Are you a seasoned Vacuum Metalizer Operator seeking a new career path? Discover our professionally built Vacuum Metalizer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

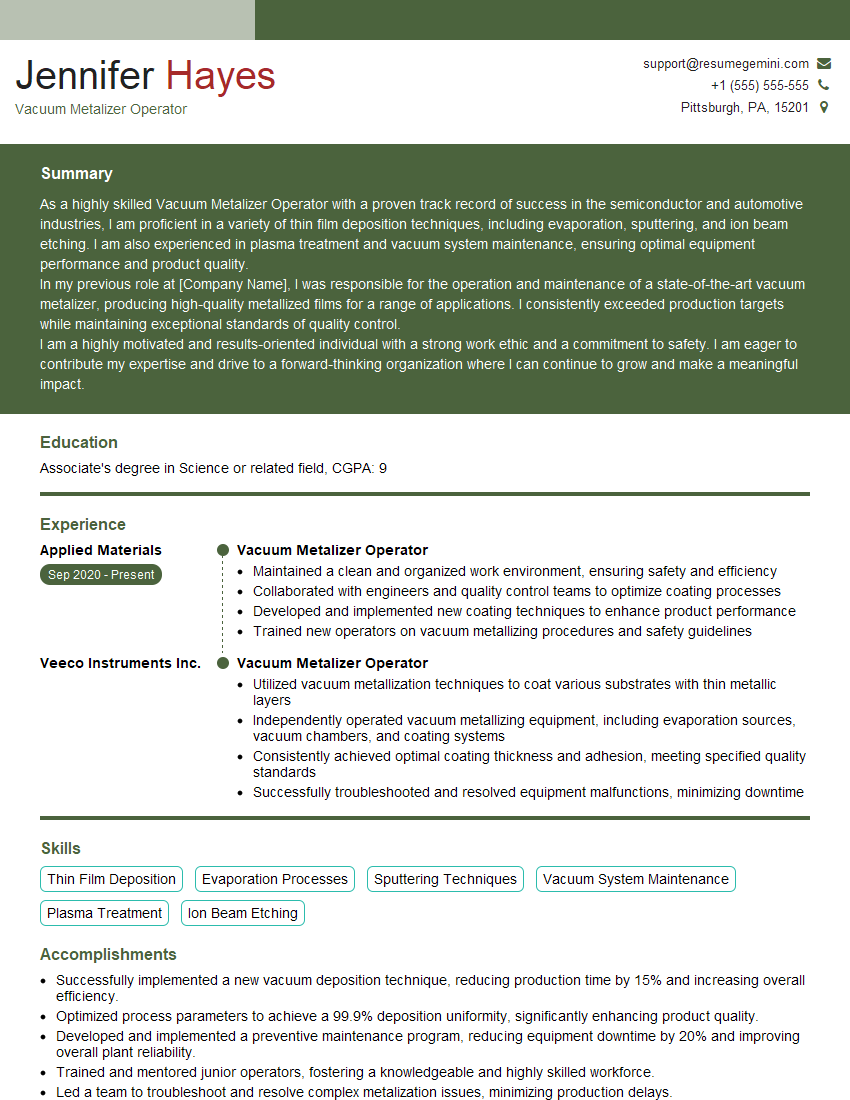

Jennifer Hayes

Vacuum Metalizer Operator

Summary

As a highly skilled Vacuum Metalizer Operator with a proven track record of success in the semiconductor and automotive industries, I am proficient in a variety of thin film deposition techniques, including evaporation, sputtering, and ion beam etching. I am also experienced in plasma treatment and vacuum system maintenance, ensuring optimal equipment performance and product quality.

In my previous role at [Company Name], I was responsible for the operation and maintenance of a state-of-the-art vacuum metalizer, producing high-quality metallized films for a range of applications. I consistently exceeded production targets while maintaining exceptional standards of quality control.

I am a highly motivated and results-oriented individual with a strong work ethic and a commitment to safety. I am eager to contribute my expertise and drive to a forward-thinking organization where I can continue to grow and make a meaningful impact.

Education

Associate’s degree in Science or related field

August 2016

Skills

- Thin Film Deposition

- Evaporation Processes

- Sputtering Techniques

- Vacuum System Maintenance

- Plasma Treatment

- Ion Beam Etching

Work Experience

Vacuum Metalizer Operator

- Maintained a clean and organized work environment, ensuring safety and efficiency

- Collaborated with engineers and quality control teams to optimize coating processes

- Developed and implemented new coating techniques to enhance product performance

- Trained new operators on vacuum metallizing procedures and safety guidelines

Vacuum Metalizer Operator

- Utilized vacuum metallization techniques to coat various substrates with thin metallic layers

- Independently operated vacuum metallizing equipment, including evaporation sources, vacuum chambers, and coating systems

- Consistently achieved optimal coating thickness and adhesion, meeting specified quality standards

- Successfully troubleshooted and resolved equipment malfunctions, minimizing downtime

Accomplishments

- Successfully implemented a new vacuum deposition technique, reducing production time by 15% and increasing overall efficiency.

- Optimized process parameters to achieve a 99.9% deposition uniformity, significantly enhancing product quality.

- Developed and implemented a preventive maintenance program, reducing equipment downtime by 20% and improving overall plant reliability.

- Trained and mentored junior operators, fostering a knowledgeable and highly skilled workforce.

- Led a team to troubleshoot and resolve complex metalization issues, minimizing production delays.

Awards

- Received the Operator of the Year award for consistently surpassing production targets and maintaining highquality standards.

- Honored with the Excellence in Metalization award for exceptional expertise and contributions to the field.

- Recognized as Top Performer for consistently exceeding expectations in productivity, quality, and customer satisfaction.

- Received the Safety Champion award for promoting a positive safety culture and ensuring a workplace free of incidents.

Certificates

- Vacuum Metalizing Certificate

- American Vacuum Society (AVS) Certification

- ISO 9001:2015 Internal Auditor

- OSHA 10-Hour General Industry Safety Certificate

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vacuum Metalizer Operator

- Highlight your technical skills and experience in thin film deposition techniques.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your knowledge of vacuum system maintenance and troubleshooting.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Vacuum Metalizer Operator Resume

- Operate and maintain vacuum metalizers to deposit thin films on various substrates

- Monitor and control process parameters to ensure optimal film quality and adhesion

- Perform preventive and corrective maintenance on vacuum systems, pumps, and other equipment

- Troubleshoot and resolve technical issues related to vacuum processes and equipment

- Maintain a clean and organized work environment in accordance with safety regulations

- Collaborate with engineers and technicians to develop and improve vacuum metalizing processes

- Stay up-to-date on the latest advancements in vacuum metalizing technology

Frequently Asked Questions (FAQ’s) For Vacuum Metalizer Operator

What is vacuum metalizing?

Vacuum metalizing is a process of depositing a thin layer of metal onto a substrate in a vacuum environment. This process is used to improve the surface properties of the substrate, such as its electrical conductivity, corrosion resistance, or reflectivity.

What are the different types of thin film deposition techniques?

There are several different thin film deposition techniques, including evaporation, sputtering, and ion beam etching. Each technique has its own advantages and disadvantages, depending on the desired film properties and substrate material.

What are the key responsibilities of a Vacuum Metalizer Operator?

The key responsibilities of a Vacuum Metalizer Operator include operating and maintaining vacuum metalizers, monitoring and controlling process parameters, performing preventive and corrective maintenance, troubleshooting technical issues, and maintaining a clean and organized work environment.

What are the career prospects for Vacuum Metalizer Operators?

Vacuum Metalizer Operators can advance their careers by gaining experience in different thin film deposition techniques, becoming certified in vacuum technology, or moving into supervisory or management roles.

What are the safety precautions that Vacuum Metalizer Operators must follow?

Vacuum Metalizer Operators must follow a number of safety precautions, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of the potential hazards of working with vacuum systems and hazardous materials.

What are the key skills that Vacuum Metalizer Operators need?

Vacuum Metalizer Operators need a strong understanding of thin film deposition techniques, vacuum system maintenance, and troubleshooting. They should also have good communication and interpersonal skills, and be able to work independently and as part of a team.