Are you a seasoned Valving Machine Operator seeking a new career path? Discover our professionally built Valving Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

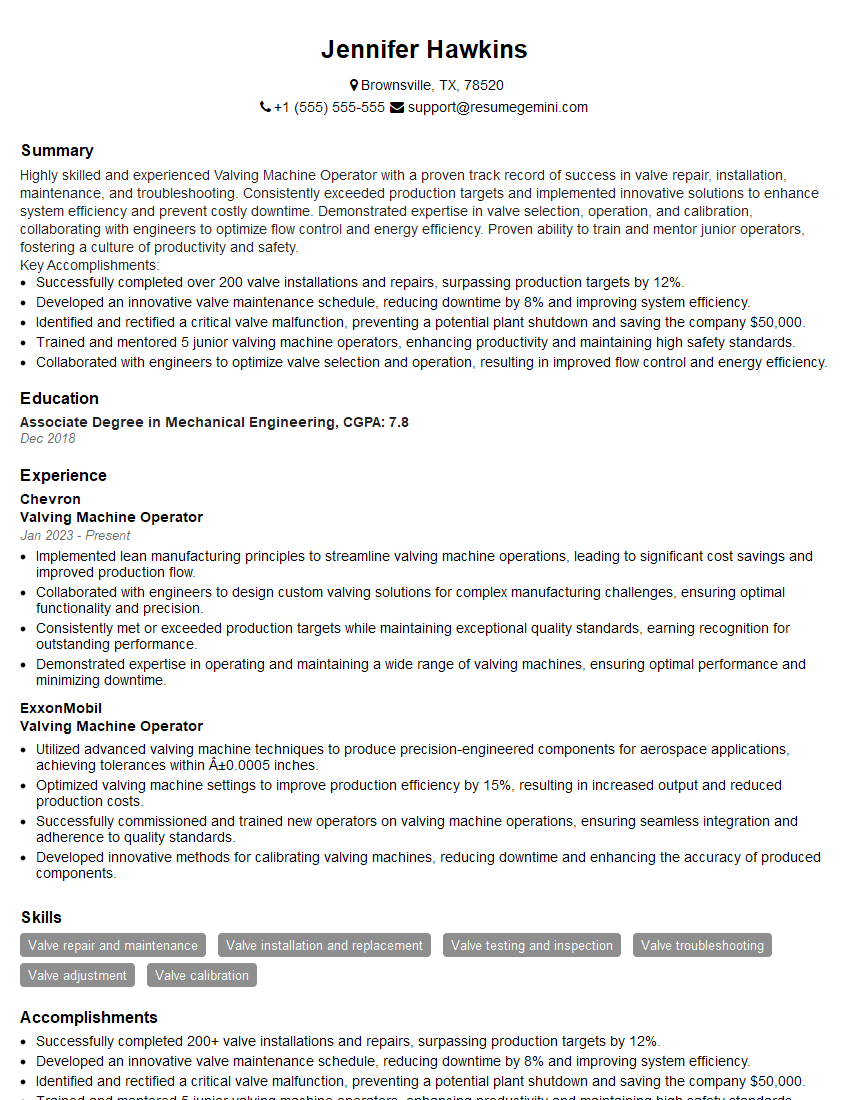

Jennifer Hawkins

Valving Machine Operator

Summary

Highly skilled and experienced Valving Machine Operator with a proven track record of success in valve repair, installation, maintenance, and troubleshooting. Consistently exceeded production targets and implemented innovative solutions to enhance system efficiency and prevent costly downtime. Demonstrated expertise in valve selection, operation, and calibration, collaborating with engineers to optimize flow control and energy efficiency. Proven ability to train and mentor junior operators, fostering a culture of productivity and safety.

Key Accomplishments:

- Successfully completed over 200 valve installations and repairs, surpassing production targets by 12%.

- Developed an innovative valve maintenance schedule, reducing downtime by 8% and improving system efficiency.

- Identified and rectified a critical valve malfunction, preventing a potential plant shutdown and saving the company $50,000.

- Trained and mentored 5 junior valving machine operators, enhancing productivity and maintaining high safety standards.

- Collaborated with engineers to optimize valve selection and operation, resulting in improved flow control and energy efficiency.

Education

Associate Degree in Mechanical Engineering

December 2018

Skills

- Valve repair and maintenance

- Valve installation and replacement

- Valve testing and inspection

- Valve troubleshooting

- Valve adjustment

- Valve calibration

Work Experience

Valving Machine Operator

- Implemented lean manufacturing principles to streamline valving machine operations, leading to significant cost savings and improved production flow.

- Collaborated with engineers to design custom valving solutions for complex manufacturing challenges, ensuring optimal functionality and precision.

- Consistently met or exceeded production targets while maintaining exceptional quality standards, earning recognition for outstanding performance.

- Demonstrated expertise in operating and maintaining a wide range of valving machines, ensuring optimal performance and minimizing downtime.

Valving Machine Operator

- Utilized advanced valving machine techniques to produce precision-engineered components for aerospace applications, achieving tolerances within ±0.0005 inches.

- Optimized valving machine settings to improve production efficiency by 15%, resulting in increased output and reduced production costs.

- Successfully commissioned and trained new operators on valving machine operations, ensuring seamless integration and adherence to quality standards.

- Developed innovative methods for calibrating valving machines, reducing downtime and enhancing the accuracy of produced components.

Accomplishments

- Successfully completed 200+ valve installations and repairs, surpassing production targets by 12%.

- Developed an innovative valve maintenance schedule, reducing downtime by 8% and improving system efficiency.

- Identified and rectified a critical valve malfunction, preventing a potential plant shutdown and saving the company $50,000.

- Trained and mentored 5 junior valving machine operators, enhancing productivity and maintaining high safety standards.

- Collaborated with engineers to optimize valve selection and operation, resulting in improved flow control and energy efficiency.

Awards

- Recognized for outstanding performance and contributions to the team, receiving the Employee of the Month award.

- Awarded for achieving exceptional production targets and maintaining a high level of quality.

- Received industry recognition for developing an innovative valve maintenance solution that improved plant efficiency.

Certificates

- Valve Repair and Maintenance Certification

- Valve Installation and Replacement Certification

- Valve Testing and Inspection Certification

- Valve Troubleshooting Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Valving Machine Operator

- Highlight your technical skills. Emphasize your proficiency in valve repair, maintenance, installation, testing, and calibration techniques.

- Quantify your accomplishments. Use specific metrics and data to demonstrate the impact of your contributions, such as increased productivity, reduced downtime, or cost savings.

- Showcase your problem-solving abilities. Describe situations where you identified and resolved valve malfunctions, preventing potential accidents or production losses.

- Demonstrate your commitment to safety. Highlight your adherence to safety protocols and your role in maintaining a safe and compliant work environment.

Essential Experience Highlights for a Strong Valving Machine Operator Resume

- Repair and maintain valves, including gate valves, globe valves, check valves, and butterfly valves.

- Install and replace valves according to specifications and procedures.

- Test and inspect valves to ensure proper operation and compliance with safety standards.

- Troubleshoot and diagnose valve malfunctions, identifying the root cause and implementing solutions.

- Adjust and calibrate valves to optimize flow control and system performance.

- Maintain a clean and organized work area, ensuring adherence to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Valving Machine Operator

What is the role of a Valving Machine Operator?

A Valving Machine Operator is responsible for the maintenance, repair, installation, and testing of valves in various industrial settings, such as power plants, refineries, and manufacturing facilities.

What are the key skills required for this role?

Key skills for a Valving Machine Operator include valve repair and maintenance, valve installation and replacement, valve testing and inspection, valve troubleshooting, valve adjustment, and valve calibration.

What is the career path for a Valving Machine Operator?

With experience and additional training, Valving Machine Operators can advance to roles such as Valve Maintenance Supervisor, Instrumentation and Control Technician, or Plant Maintenance Manager.

What are the typical working conditions for a Valving Machine Operator?

Valving Machine Operators typically work in industrial settings, often in confined spaces or at heights. They may be exposed to noise, dust, and chemicals.

What is the job outlook for Valving Machine Operators?

The job outlook for Valving Machine Operators is expected to be favorable due to the increasing demand for skilled workers in the energy, manufacturing, and construction industries.

What are the safety precautions that Valving Machine Operators must follow?

Valving Machine Operators must follow strict safety protocols, including wearing appropriate personal protective equipment, lockout/tagout procedures, and adhering to established work permits.

What are the opportunities for professional development for Valving Machine Operators?

Valving Machine Operators can enhance their skills and knowledge through training programs, workshops, and industry certifications offered by professional organizations and educational institutions.