Are you a seasoned Varnishing Unit Operator seeking a new career path? Discover our professionally built Varnishing Unit Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

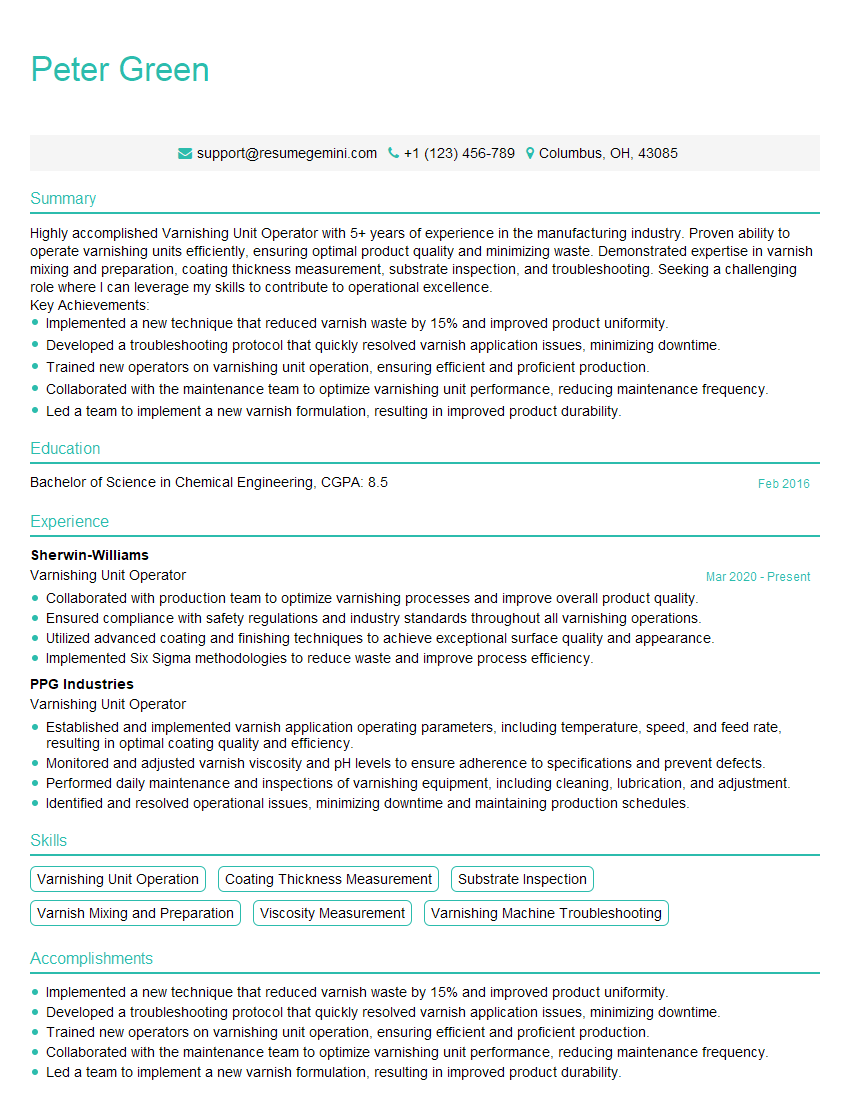

Peter Green

Varnishing Unit Operator

Summary

Highly accomplished Varnishing Unit Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate varnishing units efficiently, ensuring optimal product quality and minimizing waste. Demonstrated expertise in varnish mixing and preparation, coating thickness measurement, substrate inspection, and troubleshooting. Seeking a challenging role where I can leverage my skills to contribute to operational excellence.

Key Achievements:

- Implemented a new technique that reduced varnish waste by 15% and improved product uniformity.

- Developed a troubleshooting protocol that quickly resolved varnish application issues, minimizing downtime.

- Trained new operators on varnishing unit operation, ensuring efficient and proficient production.

- Collaborated with the maintenance team to optimize varnishing unit performance, reducing maintenance frequency.

- Led a team to implement a new varnish formulation, resulting in improved product durability.

Education

Bachelor of Science in Chemical Engineering

February 2016

Skills

- Varnishing Unit Operation

- Coating Thickness Measurement

- Substrate Inspection

- Varnish Mixing and Preparation

- Viscosity Measurement

- Varnishing Machine Troubleshooting

Work Experience

Varnishing Unit Operator

- Collaborated with production team to optimize varnishing processes and improve overall product quality.

- Ensured compliance with safety regulations and industry standards throughout all varnishing operations.

- Utilized advanced coating and finishing techniques to achieve exceptional surface quality and appearance.

- Implemented Six Sigma methodologies to reduce waste and improve process efficiency.

Varnishing Unit Operator

- Established and implemented varnish application operating parameters, including temperature, speed, and feed rate, resulting in optimal coating quality and efficiency.

- Monitored and adjusted varnish viscosity and pH levels to ensure adherence to specifications and prevent defects.

- Performed daily maintenance and inspections of varnishing equipment, including cleaning, lubrication, and adjustment.

- Identified and resolved operational issues, minimizing downtime and maintaining production schedules.

Accomplishments

- Implemented a new technique that reduced varnish waste by 15% and improved product uniformity.

- Developed a troubleshooting protocol that quickly resolved varnish application issues, minimizing downtime.

- Trained new operators on varnishing unit operation, ensuring efficient and proficient production.

- Collaborated with the maintenance team to optimize varnishing unit performance, reducing maintenance frequency.

- Led a team to implement a new varnish formulation, resulting in improved product durability.

Awards

- Awarded Employee of the Month for consistently exceeding production targets and maintaining highquality standards.

- Recognized for outstanding performance in maintaining a clean and organized work environment.

- Received Safety Award for adherence to safety protocols and contributing to a safe work atmosphere.

- Awarded for innovation in developing a new method to enhance varnish adhesion on intricate surfaces.

Certificates

- Varnishing Unit Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Varnishing Unit Operator

Highlight your technical skills.

Varnishing Unit Operators need to be proficient in the operation of varnishing units, as well as in coating thickness measurement, substrate inspection, and varnish mixing and preparation.Quantify your accomplishments.

When describing your work experience, be sure to quantify your accomplishments whenever possible. This will help employers see the impact of your work.Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. This will help your resume get noticed.Proofread carefully.

Before submitting your resume, be sure to proofread it carefully for any errors. A well-written resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Varnishing Unit Operator Resume

- Operate varnishing units to apply varnish to various substrates according to specified parameters.

- Measure coating thickness and inspect substrates to ensure adherence to quality standards.

- Mix and prepare varnish solutions according to established formulations.

- Troubleshoot and resolve varnish application issues to minimize downtime and maintain production efficiency.

- Maintain a clean and organized work area, ensuring compliance with safety regulations.

- Collaborate with other team members, including maintenance technicians and quality control personnel, to optimize varnishing processes.

- Stay abreast of industry best practices and advancements in varnishing technology.

Frequently Asked Questions (FAQ’s) For Varnishing Unit Operator

What is the role of a Varnishing Unit Operator?

Varnishing Unit Operators are responsible for operating varnishing units to apply varnish to various substrates. They also measure coating thickness, inspect substrates, mix and prepare varnish solutions, and troubleshoot varnish application issues.

What are the qualifications for a Varnishing Unit Operator?

Varnishing Unit Operators typically have a high school diploma or equivalent. They may also have some college education in chemistry or a related field. In addition, they must have experience operating varnishing units and be proficient in coating thickness measurement, substrate inspection, and varnish mixing and preparation.

What are the job duties of a Varnishing Unit Operator?

Varnishing Unit Operators perform a variety of job duties, including operating varnishing units, measuring coating thickness, inspecting substrates, mixing and preparing varnish solutions, and troubleshooting varnish application issues. They also maintain a clean and organized work area and collaborate with other team members.

What is the work environment of a Varnishing Unit Operator?

Varnishing Unit Operators typically work in manufacturing facilities. They may work indoors or outdoors, depending on the type of facility. They may also work with hazardous materials, so they must wear appropriate safety gear.

What is the salary of a Varnishing Unit Operator?

The salary of a Varnishing Unit Operator varies depending on their experience, location, and employer. According to Indeed, the average salary for a Varnishing Unit Operator in the United States is $35,000 per year.

What is the job outlook for a Varnishing Unit Operator?

The job outlook for Varnishing Unit Operators is expected to be good over the next few years. This is due to the increasing demand for varnished products in a variety of industries.