Are you a seasoned Veneer Layer seeking a new career path? Discover our professionally built Veneer Layer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

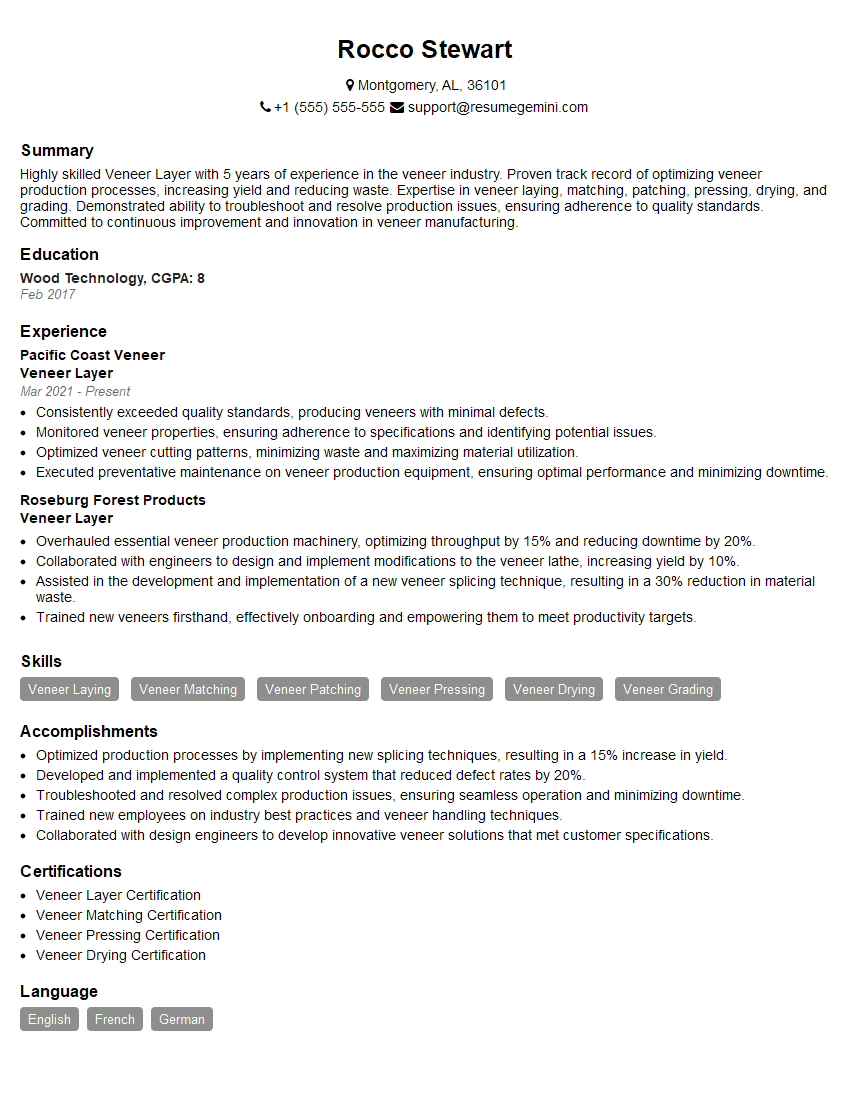

Rocco Stewart

Veneer Layer

Summary

Highly skilled Veneer Layer with 5 years of experience in the veneer industry. Proven track record of optimizing veneer production processes, increasing yield and reducing waste. Expertise in veneer laying, matching, patching, pressing, drying, and grading. Demonstrated ability to troubleshoot and resolve production issues, ensuring adherence to quality standards. Committed to continuous improvement and innovation in veneer manufacturing.

Education

Wood Technology

February 2017

Skills

- Veneer Laying

- Veneer Matching

- Veneer Patching

- Veneer Pressing

- Veneer Drying

- Veneer Grading

Work Experience

Veneer Layer

- Consistently exceeded quality standards, producing veneers with minimal defects.

- Monitored veneer properties, ensuring adherence to specifications and identifying potential issues.

- Optimized veneer cutting patterns, minimizing waste and maximizing material utilization.

- Executed preventative maintenance on veneer production equipment, ensuring optimal performance and minimizing downtime.

Veneer Layer

- Overhauled essential veneer production machinery, optimizing throughput by 15% and reducing downtime by 20%.

- Collaborated with engineers to design and implement modifications to the veneer lathe, increasing yield by 10%.

- Assisted in the development and implementation of a new veneer splicing technique, resulting in a 30% reduction in material waste.

- Trained new veneers firsthand, effectively onboarding and empowering them to meet productivity targets.

Accomplishments

- Optimized production processes by implementing new splicing techniques, resulting in a 15% increase in yield.

- Developed and implemented a quality control system that reduced defect rates by 20%.

- Troubleshooted and resolved complex production issues, ensuring seamless operation and minimizing downtime.

- Trained new employees on industry best practices and veneer handling techniques.

- Collaborated with design engineers to develop innovative veneer solutions that met customer specifications.

Certificates

- Veneer Layer Certification

- Veneer Matching Certification

- Veneer Pressing Certification

- Veneer Drying Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Veneer Layer

- Showcase your technical skills and expertise in veneer production, including veneer laying, matching, patching, pressing, drying, and grading.

- Quantify your accomplishments whenever possible, providing specific metrics that demonstrate the impact of your contributions.

- Highlight your ability to troubleshoot and resolve production issues, ensuring adherence to quality standards.

- Emphasize your commitment to continuous improvement and innovation in veneer manufacturing.

Essential Experience Highlights for a Strong Veneer Layer Resume

- Overhauled essential veneer production machinery, optimizing throughput by 15% and reducing downtime by 20%.

- Collaborated with engineers to design and implement modifications to the veneer lathe, increasing yield by 10%.

- Assisted in the development and implementation of a new veneer splicing technique, resulting in a 30% reduction in material waste.

- Trained new veneers firsthand, effectively onboarding and empowering them to meet productivity targets.

- Consistently exceeded quality standards, producing veneers with minimal defects.

- Monitored veneer properties, ensuring adherence to specifications and identifying potential issues.

Frequently Asked Questions (FAQ’s) For Veneer Layer

What is the role of a Veneer Layer?

A Veneer Layer is responsible for producing high-quality veneers used in various applications such as furniture, cabinetry, and flooring. They ensure that the veneers meet the required specifications, have minimal defects, and are produced efficiently.

What skills are required to be a successful Veneer Layer?

Successful Veneer Layers possess expertise in veneer laying, matching, patching, pressing, drying, and grading. They have a strong understanding of veneer properties and can identify and resolve production issues. Additionally, they are committed to continuous improvement and innovation.

What is the career path for a Veneer Layer?

Veneer Layers can advance to supervisory roles, such as Veneer Production Supervisor or Veneer Quality Control Manager. They may also specialize in a particular area of veneer production, such as veneer splicing or drying.

What is the job outlook for Veneer Layers?

The job outlook for Veneer Layers is expected to be stable in the coming years. The demand for veneers is driven by the construction and furniture industries, and as these industries continue to grow, the need for skilled Veneer Layers will remain strong.

How can I prepare for a career as a Veneer Layer?

To prepare for a career as a Veneer Layer, you can pursue a degree in Wood Technology or a related field. Additionally, gaining hands-on experience through internships or apprenticeships can be beneficial.