Are you a seasoned Vertical Boring Mill Operator seeking a new career path? Discover our professionally built Vertical Boring Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

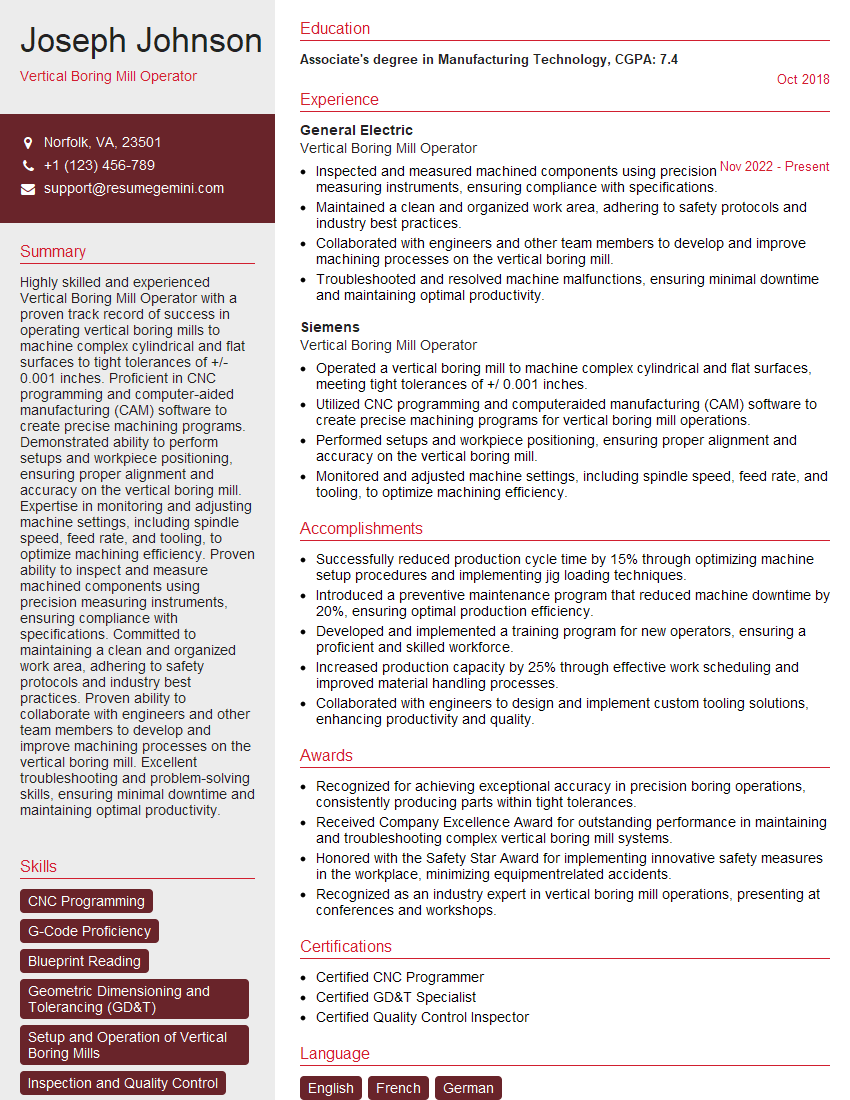

Joseph Johnson

Vertical Boring Mill Operator

Summary

Highly skilled and experienced Vertical Boring Mill Operator with a proven track record of success in operating vertical boring mills to machine complex cylindrical and flat surfaces to tight tolerances of +/- 0.001 inches. Proficient in CNC programming and computer-aided manufacturing (CAM) software to create precise machining programs. Demonstrated ability to perform setups and workpiece positioning, ensuring proper alignment and accuracy on the vertical boring mill. Expertise in monitoring and adjusting machine settings, including spindle speed, feed rate, and tooling, to optimize machining efficiency. Proven ability to inspect and measure machined components using precision measuring instruments, ensuring compliance with specifications. Committed to maintaining a clean and organized work area, adhering to safety protocols and industry best practices. Proven ability to collaborate with engineers and other team members to develop and improve machining processes on the vertical boring mill. Excellent troubleshooting and problem-solving skills, ensuring minimal downtime and maintaining optimal productivity.

Education

Associate’s degree in Manufacturing Technology

October 2018

Skills

- CNC Programming

- G-Code Proficiency

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Setup and Operation of Vertical Boring Mills

- Inspection and Quality Control

Work Experience

Vertical Boring Mill Operator

- Inspected and measured machined components using precision measuring instruments, ensuring compliance with specifications.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

- Collaborated with engineers and other team members to develop and improve machining processes on the vertical boring mill.

- Troubleshooted and resolved machine malfunctions, ensuring minimal downtime and maintaining optimal productivity.

Vertical Boring Mill Operator

- Operated a vertical boring mill to machine complex cylindrical and flat surfaces, meeting tight tolerances of +/ 0.001 inches.

- Utilized CNC programming and computeraided manufacturing (CAM) software to create precise machining programs for vertical boring mill operations.

- Performed setups and workpiece positioning, ensuring proper alignment and accuracy on the vertical boring mill.

- Monitored and adjusted machine settings, including spindle speed, feed rate, and tooling, to optimize machining efficiency.

Accomplishments

- Successfully reduced production cycle time by 15% through optimizing machine setup procedures and implementing jig loading techniques.

- Introduced a preventive maintenance program that reduced machine downtime by 20%, ensuring optimal production efficiency.

- Developed and implemented a training program for new operators, ensuring a proficient and skilled workforce.

- Increased production capacity by 25% through effective work scheduling and improved material handling processes.

- Collaborated with engineers to design and implement custom tooling solutions, enhancing productivity and quality.

Awards

- Recognized for achieving exceptional accuracy in precision boring operations, consistently producing parts within tight tolerances.

- Received Company Excellence Award for outstanding performance in maintaining and troubleshooting complex vertical boring mill systems.

- Honored with the Safety Star Award for implementing innovative safety measures in the workplace, minimizing equipmentrelated accidents.

- Recognized as an industry expert in vertical boring mill operations, presenting at conferences and workshops.

Certificates

- Certified CNC Programmer

- Certified GD&T Specialist

- Certified Quality Control Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vertical Boring Mill Operator

- Highlight your skills and experience in CNC programming and computer-aided manufacturing (CAM) software.

- Showcase your ability to operate a vertical boring mill to tight tolerances of +/- 0.001 inches.

- Emphasize your experience in performing setups and workpiece positioning, ensuring proper alignment and accuracy.

- Demonstrate your ability to monitor and adjust machine settings, including spindle speed, feed rate, and tooling, to optimize machining efficiency.

- Highlight your experience in inspecting and measuring machined components using precision measuring instruments, ensuring compliance with specifications.

Essential Experience Highlights for a Strong Vertical Boring Mill Operator Resume

- Operate a vertical boring mill to machine complex cylindrical and flat surfaces, meeting tight tolerances of +/ 0.001 inches.

- Utilize CNC programming and computer-aided manufacturing (CAM) software to create precise machining programs for vertical boring mill operations.

- Perform setups and workpiece positioning, ensuring proper alignment and accuracy on the vertical boring mill.

- Monitor and adjust machine settings, including spindle speed, feed rate, and tooling, to optimize machining efficiency.

- Inspect and measure machined components using precision measuring instruments, ensuring compliance with specifications.

- Maintain a clean and organized work area, adhering to safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Vertical Boring Mill Operator

What is a Vertical Boring Mill Operator?

A Vertical Boring Mill Operator is responsible for operating a vertical boring mill to machine complex cylindrical and flat surfaces, meeting tight tolerances of +/- 0.001 inches. They utilize CNC programming and computer-aided manufacturing (CAM) software to create precise machining programs for vertical boring mill operations. They perform setups and workpiece positioning, ensuring proper alignment and accuracy on the vertical boring mill. They monitor and adjust machine settings, including spindle speed, feed rate, and tooling, to optimize machining efficiency. They inspect and measure machined components using precision measuring instruments, ensuring compliance with specifications. They maintain a clean and organized work area, adhering to safety protocols and industry best practices.

What skills are required to be a Vertical Boring Mill Operator?

CNC programming, G-Code Proficiency, Blueprint Reading, Geometric Dimensioning and Tolerancing (GD&T), Setup and Operation of Vertical Boring Mills, Inspection and Quality Control

What is the average salary for a Vertical Boring Mill Operator?

The average salary for a Vertical Boring Mill Operator in the United States is $50,000 per year.

What is the job outlook for Vertical Boring Mill Operators?

The job outlook for Vertical Boring Mill Operators is expected to grow 4% from 2019 to 2029.

What are the working conditions for Vertical Boring Mill Operators?

Vertical Boring Mill Operators typically work in a machine shop environment. They may be exposed to loud noise, dust, and fumes. They must be able to stand for long periods of time and lift heavy objects.

What are the benefits of being a Vertical Boring Mill Operator?

Vertical Boring Mill Operators can enjoy a good salary and benefits package. They also have the opportunity to work with advanced machinery and technology. They can also take pride in knowing that they are playing a role in the manufacturing of important products.