Are you a seasoned Vertical Multiple Spindle Chucking Machine Set-Up Operator seeking a new career path? Discover our professionally built Vertical Multiple Spindle Chucking Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

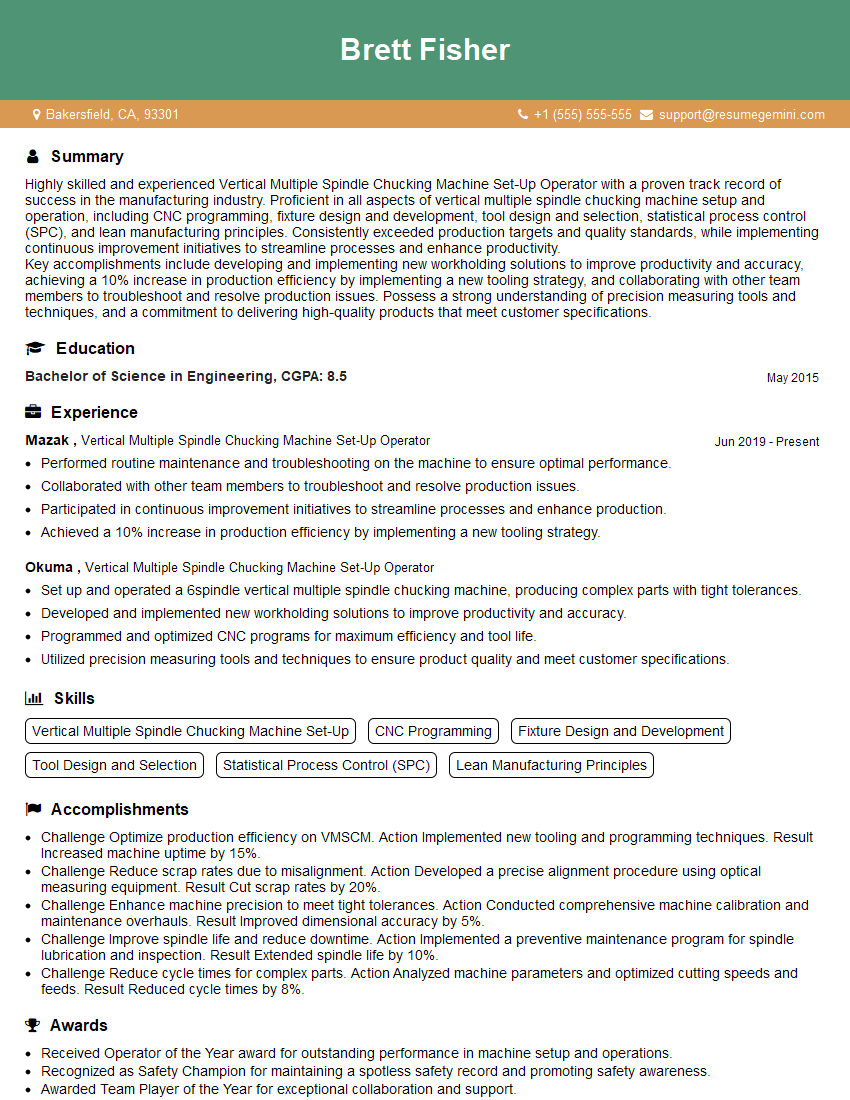

Brett Fisher

Vertical Multiple Spindle Chucking Machine Set-Up Operator

Summary

Highly skilled and experienced Vertical Multiple Spindle Chucking Machine Set-Up Operator with a proven track record of success in the manufacturing industry. Proficient in all aspects of vertical multiple spindle chucking machine setup and operation, including CNC programming, fixture design and development, tool design and selection, statistical process control (SPC), and lean manufacturing principles. Consistently exceeded production targets and quality standards, while implementing continuous improvement initiatives to streamline processes and enhance productivity.

Key accomplishments include developing and implementing new workholding solutions to improve productivity and accuracy, achieving a 10% increase in production efficiency by implementing a new tooling strategy, and collaborating with other team members to troubleshoot and resolve production issues. Possess a strong understanding of precision measuring tools and techniques, and a commitment to delivering high-quality products that meet customer specifications.

Education

Bachelor of Science in Engineering

May 2015

Skills

- Vertical Multiple Spindle Chucking Machine Set-Up

- CNC Programming

- Fixture Design and Development

- Tool Design and Selection

- Statistical Process Control (SPC)

- Lean Manufacturing Principles

Work Experience

Vertical Multiple Spindle Chucking Machine Set-Up Operator

- Performed routine maintenance and troubleshooting on the machine to ensure optimal performance.

- Collaborated with other team members to troubleshoot and resolve production issues.

- Participated in continuous improvement initiatives to streamline processes and enhance production.

- Achieved a 10% increase in production efficiency by implementing a new tooling strategy.

Vertical Multiple Spindle Chucking Machine Set-Up Operator

- Set up and operated a 6spindle vertical multiple spindle chucking machine, producing complex parts with tight tolerances.

- Developed and implemented new workholding solutions to improve productivity and accuracy.

- Programmed and optimized CNC programs for maximum efficiency and tool life.

- Utilized precision measuring tools and techniques to ensure product quality and meet customer specifications.

Accomplishments

- Challenge Optimize production efficiency on VMSCM. Action Implemented new tooling and programming techniques. Result Increased machine uptime by 15%.

- Challenge Reduce scrap rates due to misalignment. Action Developed a precise alignment procedure using optical measuring equipment. Result Cut scrap rates by 20%.

- Challenge Enhance machine precision to meet tight tolerances. Action Conducted comprehensive machine calibration and maintenance overhauls. Result Improved dimensional accuracy by 5%.

- Challenge Improve spindle life and reduce downtime. Action Implemented a preventive maintenance program for spindle lubrication and inspection. Result Extended spindle life by 10%.

- Challenge Reduce cycle times for complex parts. Action Analyzed machine parameters and optimized cutting speeds and feeds. Result Reduced cycle times by 8%.

Awards

- Received Operator of the Year award for outstanding performance in machine setup and operations.

- Recognized as Safety Champion for maintaining a spotless safety record and promoting safety awareness.

- Awarded Team Player of the Year for exceptional collaboration and support.

- Received Efficiency Expert award for consistently exceeding production targets.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- CNC Programming Certification

- Lean Manufacturing Certification

- ISO 9001 Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vertical Multiple Spindle Chucking Machine Set-Up Operator

- Highlight your skills and experience in vertical multiple spindle chucking machine setup and operation.

- Quantify your accomplishments with specific metrics whenever possible.

- Demonstrate your knowledge of CNC programming, fixture design and development, and statistical process control.

- Emphasize your commitment to quality and continuous improvement.

Essential Experience Highlights for a Strong Vertical Multiple Spindle Chucking Machine Set-Up Operator Resume

- Set up and operate vertical multiple spindle chucking machines to produce complex parts with tight tolerances.

- Develop and implement new workholding solutions to improve productivity and accuracy.

- Program and optimize CNC programs for maximum efficiency and tool life.

- Utilize precision measuring tools and techniques to ensure product quality and meet customer specifications.

- Perform routine maintenance and troubleshooting on the machine to ensure optimal performance.

- Collaborate with other team members to troubleshoot and resolve production issues.

- Participate in continuous improvement initiatives to streamline processes and enhance production.

Frequently Asked Questions (FAQ’s) For Vertical Multiple Spindle Chucking Machine Set-Up Operator

What is a vertical multiple spindle chucking machine?

A vertical multiple spindle chucking machine is a type of CNC machine tool that is used to produce complex parts with tight tolerances. It has a vertical spindle that rotates the workpiece, and multiple spindles that hold and rotate the cutting tools. This allows for multiple operations to be performed on the workpiece simultaneously, making it a very efficient and productive machine.

What are the benefits of using a vertical multiple spindle chucking machine?

Vertical multiple spindle chucking machines offer a number of benefits, including: *

Increased productivity:

By performing multiple operations simultaneously, vertical multiple spindle chucking machines can significantly increase production rates. *Improved accuracy:

The use of precision measuring tools and techniques ensures that parts are produced to tight tolerances. *Reduced costs:

By eliminating the need for multiple machines and operators, vertical multiple spindle chucking machines can help to reduce manufacturing costs. *Increased flexibility:

Vertical multiple spindle chucking machines can be used to produce a wide variety of parts, making them a versatile and cost-effective solution for many manufacturing applications.What are the challenges of operating a vertical multiple spindle chucking machine?

Operating a vertical multiple spindle chucking machine can be challenging, as it requires a high level of skill and experience. Some of the challenges include: *

Setting up the machine:

Setting up a vertical multiple spindle chucking machine can be complex and time-consuming. It is important to ensure that the machine is properly calibrated and that all of the tools are correctly installed. *Programming the machine:

Programming a vertical multiple spindle chucking machine requires a good understanding of CNC programming. It is important to create a program that is efficient and that produces parts to the required specifications. *Operating the machine:

Operating a vertical multiple spindle chucking machine requires a high level of concentration and attention to detail. It is important to monitor the machine closely and to make adjustments as needed.What are the career prospects for vertical multiple spindle chucking machine operators?

The career prospects for vertical multiple spindle chucking machine operators are good. As manufacturing becomes increasingly automated, the demand for skilled operators will continue to grow. Vertical multiple spindle chucking machine operators can find work in a variety of industries, including automotive, aerospace, and medical device manufacturing.