Are you a seasoned Vessel Slagman seeking a new career path? Discover our professionally built Vessel Slagman Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

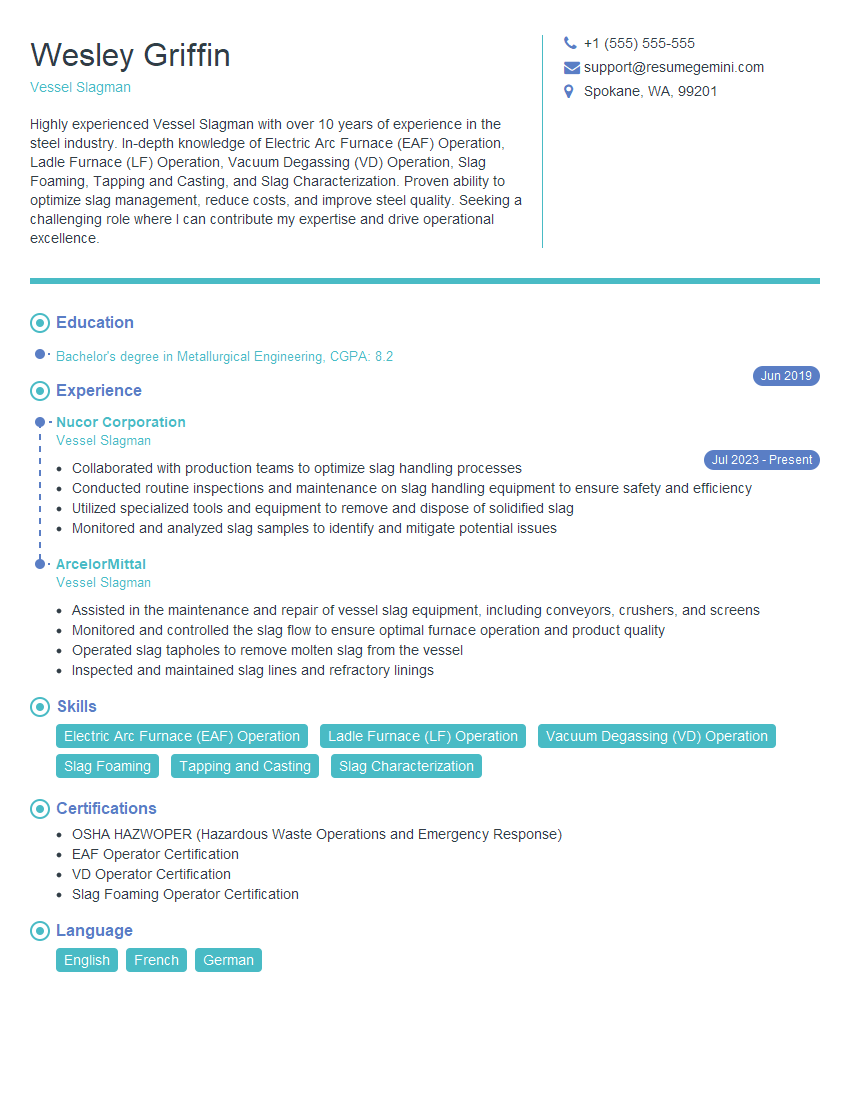

Wesley Griffin

Vessel Slagman

Summary

Highly experienced Vessel Slagman with over 10 years of experience in the steel industry. In-depth knowledge of Electric Arc Furnace (EAF) Operation, Ladle Furnace (LF) Operation, Vacuum Degassing (VD) Operation, Slag Foaming, Tapping and Casting, and Slag Characterization. Proven ability to optimize slag management, reduce costs, and improve steel quality. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Bachelor’s degree in Metallurgical Engineering

June 2019

Skills

- Electric Arc Furnace (EAF) Operation

- Ladle Furnace (LF) Operation

- Vacuum Degassing (VD) Operation

- Slag Foaming

- Tapping and Casting

- Slag Characterization

Work Experience

Vessel Slagman

- Collaborated with production teams to optimize slag handling processes

- Conducted routine inspections and maintenance on slag handling equipment to ensure safety and efficiency

- Utilized specialized tools and equipment to remove and dispose of solidified slag

- Monitored and analyzed slag samples to identify and mitigate potential issues

Vessel Slagman

- Assisted in the maintenance and repair of vessel slag equipment, including conveyors, crushers, and screens

- Monitored and controlled the slag flow to ensure optimal furnace operation and product quality

- Operated slag tapholes to remove molten slag from the vessel

- Inspected and maintained slag lines and refractory linings

Certificates

- OSHA HAZWOPER (Hazardous Waste Operations and Emergency Response)

- EAF Operator Certification

- VD Operator Certification

- Slag Foaming Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vessel Slagman

- Highlight your experience in EAF, LF, and VD operations, as well as your knowledge of slag characterization and management.

- Quantify your accomplishments and provide specific examples of how you have optimized slag management and improved steel quality.

- Demonstrate your understanding of safety protocols and environmental regulations related to slag handling and disposal.

- Tailor your resume to the specific requirements of the job you are applying for. Highlight the skills and experience that are most relevant to the role.

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Vessel Slagman Resume

- Operate and maintain Electric Arc Furnaces (EAFs), Ladle Furnaces (LFs), and Vacuum Degassing (VD) units to produce high-quality steel.

- Develop and implement slag management strategies to optimize slag composition, minimize slag volume, and reduce operating costs.

- Conduct slag characterization tests to determine slag composition, viscosity, and foaming properties.

- Troubleshoot and resolve operational issues related to slag foaming, tapping, and casting.

- Ensure adherence to safety protocols and environmental regulations related to slag handling and disposal.

- Collaborate with other team members to optimize production processes and improve overall plant efficiency.

Frequently Asked Questions (FAQ’s) For Vessel Slagman

What is the role of a Vessel Slagman?

A Vessel Slagman is responsible for managing slag, a byproduct of steel production, in electric arc furnaces, ladle furnaces, and vacuum degassing units. They optimize slag composition, minimize slag volume, and ensure adherence to safety and environmental regulations related to slag handling and disposal.

What are the key skills required for a Vessel Slagman?

Key skills for a Vessel Slagman include knowledge of EAF, LF, and VD operations, slag characterization and management, troubleshooting, and adherence to safety and environmental regulations.

What is the career path for a Vessel Slagman?

Vessel Slagmen can advance to roles such as Production Supervisor, Plant Manager, or Technical Manager in the steel industry.

What are the job prospects for Vessel Slagmen?

Job prospects for Vessel Slagmen are expected to be good as the steel industry continues to grow. There is a demand for skilled professionals who can optimize slag management and improve steel quality.

What is the average salary for a Vessel Slagman?

The average salary for a Vessel Slagman in the United States is around $70,000 per year.

What are the working conditions for a Vessel Slagman?

Vessel Slagmen typically work in steel mills, which can be hot, noisy, and dusty. They may also work in shifts, including nights and weekends.

What are the benefits of being a Vessel Slagman?

Benefits of being a Vessel Slagman include job security, competitive salaries, and the opportunity to work in a challenging and rewarding field.

What are the challenges of being a Vessel Slagman?

Challenges of being a Vessel Slagman include working in a hot, noisy, and dusty environment, as well as working in shifts, including nights and weekends.