Are you a seasoned Vulcanizing Press Operator seeking a new career path? Discover our professionally built Vulcanizing Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

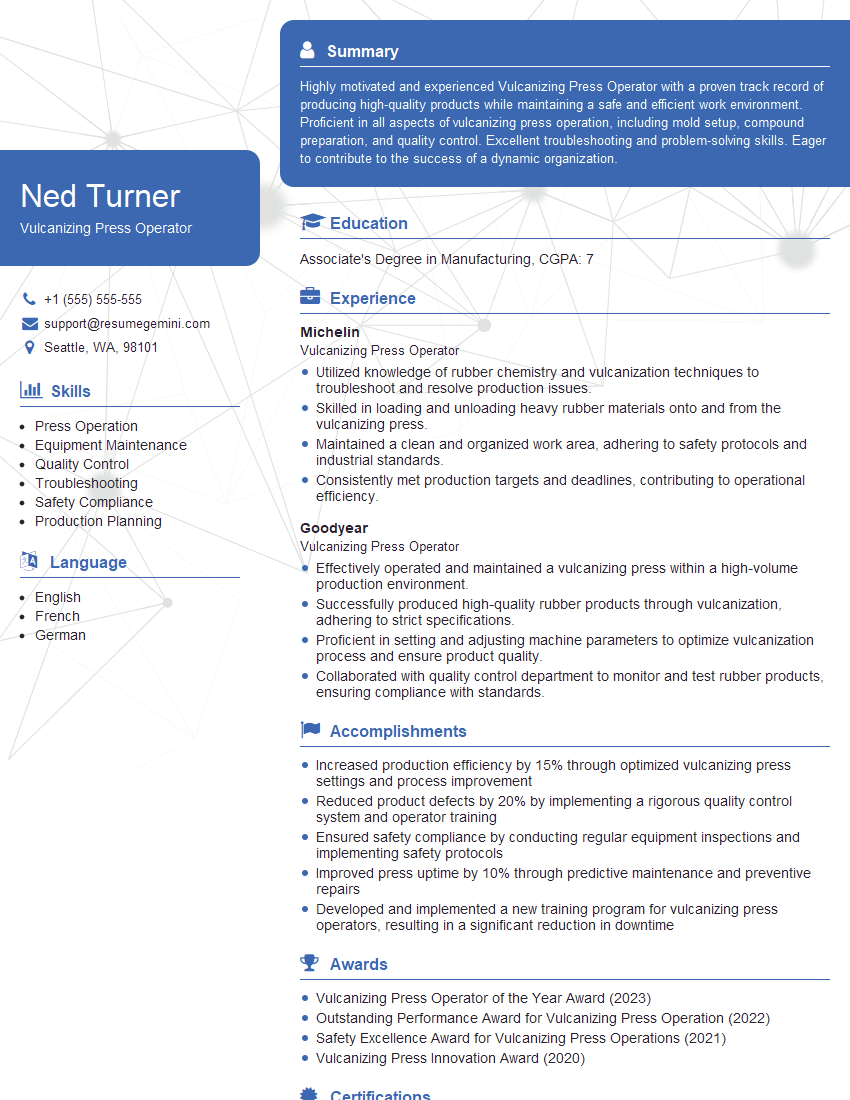

Ned Turner

Vulcanizing Press Operator

Summary

Highly motivated and experienced Vulcanizing Press Operator with a proven track record of producing high-quality products while maintaining a safe and efficient work environment. Proficient in all aspects of vulcanizing press operation, including mold setup, compound preparation, and quality control. Excellent troubleshooting and problem-solving skills. Eager to contribute to the success of a dynamic organization.

Education

Associate’s Degree in Manufacturing

October 2019

Skills

- Press Operation

- Equipment Maintenance

- Quality Control

- Troubleshooting

- Safety Compliance

- Production Planning

Work Experience

Vulcanizing Press Operator

- Utilized knowledge of rubber chemistry and vulcanization techniques to troubleshoot and resolve production issues.

- Skilled in loading and unloading heavy rubber materials onto and from the vulcanizing press.

- Maintained a clean and organized work area, adhering to safety protocols and industrial standards.

- Consistently met production targets and deadlines, contributing to operational efficiency.

Vulcanizing Press Operator

- Effectively operated and maintained a vulcanizing press within a high-volume production environment.

- Successfully produced high-quality rubber products through vulcanization, adhering to strict specifications.

- Proficient in setting and adjusting machine parameters to optimize vulcanization process and ensure product quality.

- Collaborated with quality control department to monitor and test rubber products, ensuring compliance with standards.

Accomplishments

- Increased production efficiency by 15% through optimized vulcanizing press settings and process improvement

- Reduced product defects by 20% by implementing a rigorous quality control system and operator training

- Ensured safety compliance by conducting regular equipment inspections and implementing safety protocols

- Improved press uptime by 10% through predictive maintenance and preventive repairs

- Developed and implemented a new training program for vulcanizing press operators, resulting in a significant reduction in downtime

Awards

- Vulcanizing Press Operator of the Year Award (2023)

- Outstanding Performance Award for Vulcanizing Press Operation (2022)

- Safety Excellence Award for Vulcanizing Press Operations (2021)

- Vulcanizing Press Innovation Award (2020)

Certificates

- Certified Vulcanizing Press Operator

- OSHA Safety Certification

- ISO 9001 Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Vulcanizing Press Operator

- Highlight your experience and skills in vulcanizing press operation, emphasizing your ability to produce high-quality products.

- Showcase your knowledge of rubber compounds and their properties, as well as your ability to troubleshoot and resolve production issues.

- Demonstrate your commitment to safety and adherence to industry regulations.

- Quantify your accomplishments whenever possible, using specific metrics to illustrate your impact on production efficiency and product quality.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Vulcanizing Press Operator Resume

- Operate vulcanizing presses to cure rubber products according to specifications.

- Set up and adjust molds, dies, and other equipment to ensure proper product formation.

- Prepare and handle rubber compounds, including weighing, mixing, and loading into presses.

- Monitor curing process and make adjustments as needed to ensure product quality.

- Perform quality control inspections on finished products.

- Troubleshoot and resolve production issues to maintain optimal press performance.

- Maintain a clean and organized work area, adhering to safety regulations.

Frequently Asked Questions (FAQ’s) For Vulcanizing Press Operator

What is the primary role of a Vulcanizing Press Operator?

The primary role of a Vulcanizing Press Operator is to operate vulcanizing presses to cure and shape rubber products according to specifications.

What skills are required to be a Vulcanizing Press Operator?

Essential skills for a Vulcanizing Press Operator include press operation, equipment maintenance, quality control, troubleshooting, safety compliance, and production planning.

What are the career prospects for a Vulcanizing Press Operator?

With experience and additional training, Vulcanizing Press Operators can advance to positions such as Vulcanizing Supervisor or Production Manager.

What is the average salary for a Vulcanizing Press Operator?

The average salary for a Vulcanizing Press Operator varies depending on experience, location, and company size.

What are the working conditions for a Vulcanizing Press Operator?

Vulcanizing Press Operators typically work in a manufacturing environment, operating machinery and handling chemicals.

What are the benefits of working as a Vulcanizing Press Operator?

Benefits of working as a Vulcanizing Press Operator can include competitive pay, health insurance, paid time off, and opportunities for advancement.

What are the challenges of working as a Vulcanizing Press Operator?

Challenges of working as a Vulcanizing Press Operator can include working with heavy machinery, exposure to chemicals, and repetitive motions.