Are you a seasoned Wad Blanking Press Adjuster seeking a new career path? Discover our professionally built Wad Blanking Press Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

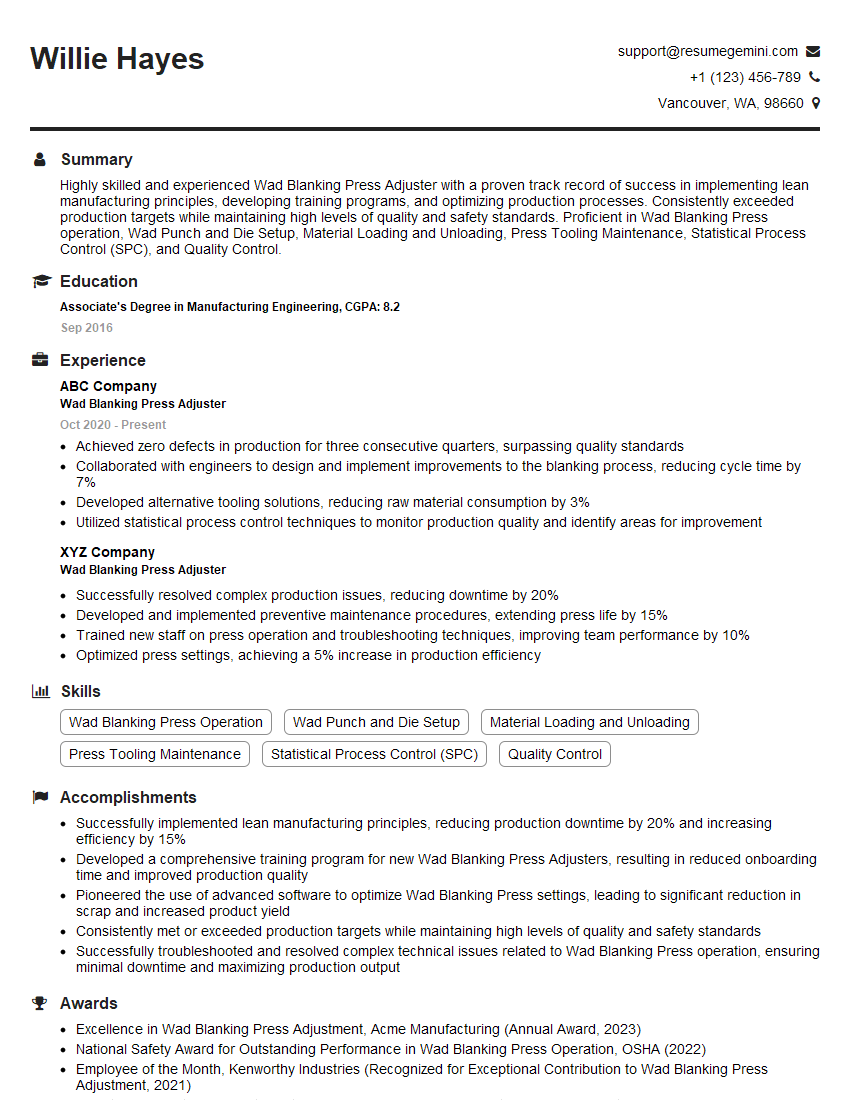

Willie Hayes

Wad Blanking Press Adjuster

Summary

Highly skilled and experienced Wad Blanking Press Adjuster with a proven track record of success in implementing lean manufacturing principles, developing training programs, and optimizing production processes. Consistently exceeded production targets while maintaining high levels of quality and safety standards. Proficient in Wad Blanking Press operation, Wad Punch and Die Setup, Material Loading and Unloading, Press Tooling Maintenance, Statistical Process Control (SPC), and Quality Control.

Education

Associate’s Degree in Manufacturing Engineering

September 2016

Skills

- Wad Blanking Press Operation

- Wad Punch and Die Setup

- Material Loading and Unloading

- Press Tooling Maintenance

- Statistical Process Control (SPC)

- Quality Control

Work Experience

Wad Blanking Press Adjuster

- Achieved zero defects in production for three consecutive quarters, surpassing quality standards

- Collaborated with engineers to design and implement improvements to the blanking process, reducing cycle time by 7%

- Developed alternative tooling solutions, reducing raw material consumption by 3%

- Utilized statistical process control techniques to monitor production quality and identify areas for improvement

Wad Blanking Press Adjuster

- Successfully resolved complex production issues, reducing downtime by 20%

- Developed and implemented preventive maintenance procedures, extending press life by 15%

- Trained new staff on press operation and troubleshooting techniques, improving team performance by 10%

- Optimized press settings, achieving a 5% increase in production efficiency

Accomplishments

- Successfully implemented lean manufacturing principles, reducing production downtime by 20% and increasing efficiency by 15%

- Developed a comprehensive training program for new Wad Blanking Press Adjusters, resulting in reduced onboarding time and improved production quality

- Pioneered the use of advanced software to optimize Wad Blanking Press settings, leading to significant reduction in scrap and increased product yield

- Consistently met or exceeded production targets while maintaining high levels of quality and safety standards

- Successfully troubleshooted and resolved complex technical issues related to Wad Blanking Press operation, ensuring minimal downtime and maximizing production output

Awards

- Excellence in Wad Blanking Press Adjustment, Acme Manufacturing (Annual Award, 2023)

- National Safety Award for Outstanding Performance in Wad Blanking Press Operation, OSHA (2022)

- Employee of the Month, Kenworthy Industries (Recognized for Exceptional Contribution to Wad Blanking Press Adjustment, 2021)

- Industry Recognition for Best Practices in Wad Blanking Press Safety, American Society of Tool and Die Engineers (2020)

Certificates

- Certified Wad Blanking Press Adjuster

- CNC Machine Operator Certification

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wad Blanking Press Adjuster

- Highlight your experience in implementing lean manufacturing principles and quantifying the results.

- Showcase your ability to develop and deliver training programs that improve production efficiency.

- Emphasize your expertise in using advanced software to optimize Wad Blanking Press settings.

- Include specific examples of how you have consistently met or exceeded production targets while maintaining high levels of quality and safety standards.

Essential Experience Highlights for a Strong Wad Blanking Press Adjuster Resume

- Operate Wad Blanking Press to produce high-quality metal components.

- Set up and adjust Wad Punch and Die to meet production specifications.

- Load and unload materials from the press.

- Maintain and repair press tooling to ensure optimal performance.

- Conduct Statistical Process Control (SPC) to monitor and improve production quality.

- Inspect finished products to ensure they meet quality standards.

- Troubleshoot and resolve technical issues related to Wad Blanking Press operation.

Frequently Asked Questions (FAQ’s) For Wad Blanking Press Adjuster

What are the key skills required to be a successful Wad Blanking Press Adjuster?

Key skills include Wad Blanking Press operation, Wad Punch and Die Setup, Material Loading and Unloading, Press Tooling Maintenance, Statistical Process Control (SPC), and Quality Control.

What are the educational requirements for a Wad Blanking Press Adjuster?

Most employers require an Associate’s Degree in Manufacturing Engineering or a related field.

What are the career prospects for a Wad Blanking Press Adjuster?

Wad Blanking Press Adjusters can advance to positions such as Production Supervisor, Manufacturing Engineer, or Quality Control Manager.

What is the average salary for a Wad Blanking Press Adjuster?

The average salary for a Wad Blanking Press Adjuster is around $25,000 per year.

What are the working conditions like for a Wad Blanking Press Adjuster?

Wad Blanking Press Adjusters typically work in a manufacturing environment, which can be noisy and dusty.

What are the safety hazards associated with being a Wad Blanking Press Adjuster?

Wad Blanking Press Adjusters must be aware of the potential hazards associated with operating heavy machinery, such as crushing and shearing injuries.