Are you a seasoned Wafer Abrading Machine Tender seeking a new career path? Discover our professionally built Wafer Abrading Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

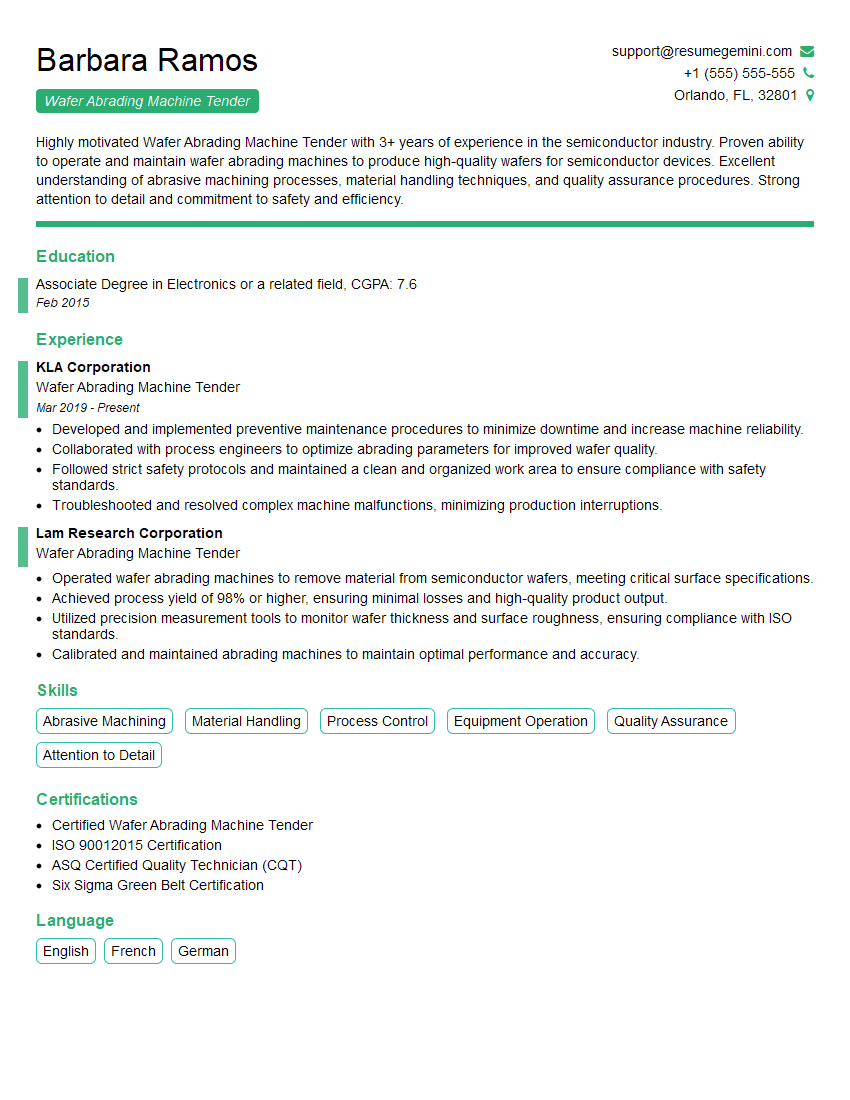

Barbara Ramos

Wafer Abrading Machine Tender

Summary

Highly motivated Wafer Abrading Machine Tender with 3+ years of experience in the semiconductor industry. Proven ability to operate and maintain wafer abrading machines to produce high-quality wafers for semiconductor devices. Excellent understanding of abrasive machining processes, material handling techniques, and quality assurance procedures. Strong attention to detail and commitment to safety and efficiency.

Education

Associate Degree in Electronics or a related field

February 2015

Skills

- Abrasive Machining

- Material Handling

- Process Control

- Equipment Operation

- Quality Assurance

- Attention to Detail

Work Experience

Wafer Abrading Machine Tender

- Developed and implemented preventive maintenance procedures to minimize downtime and increase machine reliability.

- Collaborated with process engineers to optimize abrading parameters for improved wafer quality.

- Followed strict safety protocols and maintained a clean and organized work area to ensure compliance with safety standards.

- Troubleshooted and resolved complex machine malfunctions, minimizing production interruptions.

Wafer Abrading Machine Tender

- Operated wafer abrading machines to remove material from semiconductor wafers, meeting critical surface specifications.

- Achieved process yield of 98% or higher, ensuring minimal losses and high-quality product output.

- Utilized precision measurement tools to monitor wafer thickness and surface roughness, ensuring compliance with ISO standards.

- Calibrated and maintained abrading machines to maintain optimal performance and accuracy.

Certificates

- Certified Wafer Abrading Machine Tender

- ISO 90012015 Certification

- ASQ Certified Quality Technician (CQT)

- Six Sigma Green Belt Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Abrading Machine Tender

- Highlight your experience with specific types of wafer abrading machines, such as CMP or PSG.

- Quantify your accomplishments by providing specific metrics, such as number of wafers processed or reduction in defect rates.

- Demonstrate your knowledge of wafer preparation processes and quality control techniques.

- Emphasize your attention to detail and ability to work in a fast-paced and cleanroom environment.

Essential Experience Highlights for a Strong Wafer Abrading Machine Tender Resume

- Operate wafer abrading machines to prepare wafers for semiconductor device fabrication

- Monitor and adjust machine parameters to ensure optimal performance and wafer quality

- Handle and transport wafers using proper techniques to prevent damage or contamination

- Perform periodic maintenance and calibration of wafer abrading machines to maintain accuracy and precision

- Inspect wafers for defects and take corrective actions to maintain quality standards

- Collaborate with engineers and technicians to troubleshoot and resolve machine or process issues

- Maintain a clean and organized work environment to prevent contamination and ensure safety

Frequently Asked Questions (FAQ’s) For Wafer Abrading Machine Tender

What is the role of a Wafer Abrading Machine Tender?

A Wafer Abrading Machine Tender operates and maintains wafer abrading machines to prepare wafers for semiconductor device fabrication. This involves setting up and operating the machine, monitoring its performance, and inspecting wafers for defects.

What are the key skills required for this role?

Key skills for a Wafer Abrading Machine Tender include: abrasive machining, material handling, process control, equipment operation, quality assurance, and attention to detail.

What is the typical work environment for a Wafer Abrading Machine Tender?

Wafer Abrading Machine Tenders typically work in a cleanroom environment where they are responsible for operating and maintaining wafer abrading machines. They must follow strict safety procedures and maintain a high level of cleanliness to prevent contamination of the wafers.

What are the career advancement opportunities for a Wafer Abrading Machine Tender?

With experience and additional training, Wafer Abrading Machine Tenders can advance to roles such as Process Technician, Quality Control Inspector, or Equipment Maintenance Technician.

What is the expected salary range for this role?

The salary range for a Wafer Abrading Machine Tender can vary depending on factors such as experience, location, and company size. However, the average salary range is between $40,000 and $60,000 per year.

What are the educational requirements for this role?

While a high school diploma is typically the minimum requirement for a Wafer Abrading Machine Tender, many employers prefer candidates with an associate degree in electronics or a related field.

What are the benefits of working as a Wafer Abrading Machine Tender?

Benefits of working as a Wafer Abrading Machine Tender include: competitive salary, stable employment, opportunities for career advancement, and a chance to work in a fast-paced and challenging environment.

What are the challenges of working as a Wafer Abrading Machine Tender?

Challenges of working as a Wafer Abrading Machine Tender include: working in a cleanroom environment, following strict safety procedures, and maintaining a high level of attention to detail.