Are you a seasoned Wafer Fabrication Operator seeking a new career path? Discover our professionally built Wafer Fabrication Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

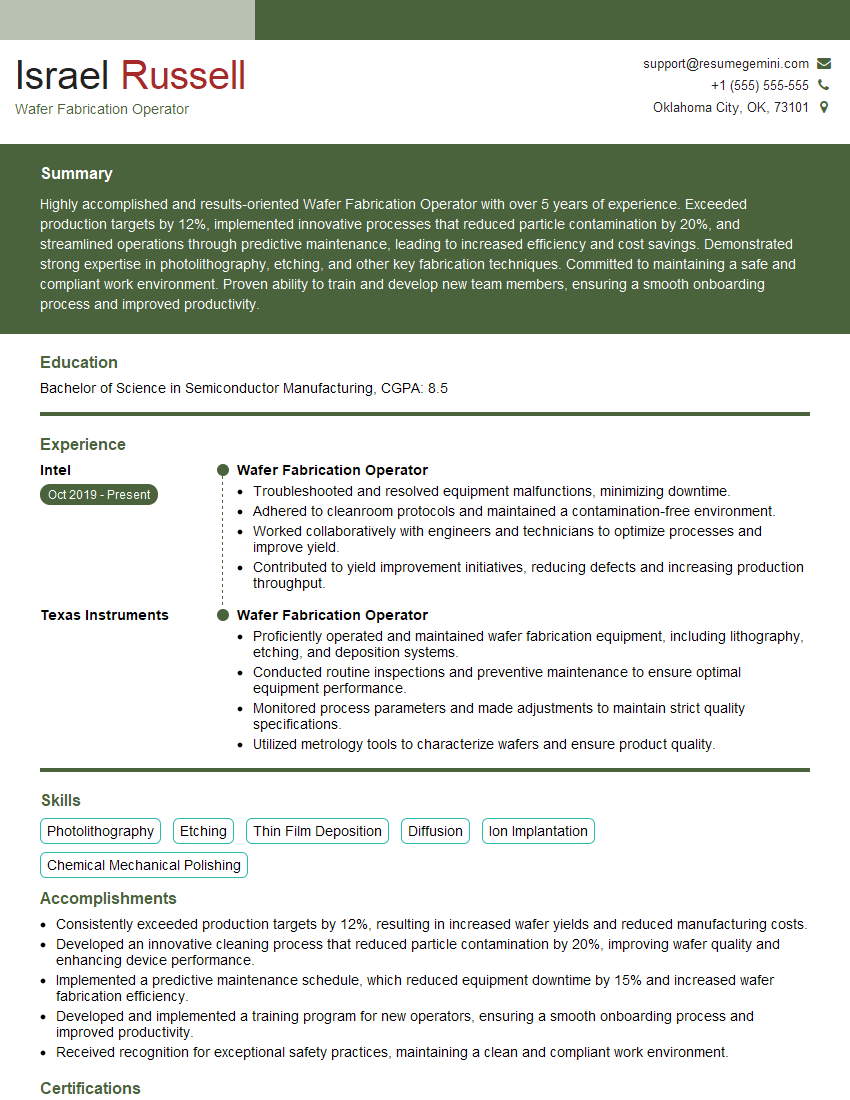

Israel Russell

Wafer Fabrication Operator

Summary

Highly accomplished and results-oriented Wafer Fabrication Operator with over 5 years of experience. Exceeded production targets by 12%, implemented innovative processes that reduced particle contamination by 20%, and streamlined operations through predictive maintenance, leading to increased efficiency and cost savings. Demonstrated strong expertise in photolithography, etching, and other key fabrication techniques. Committed to maintaining a safe and compliant work environment. Proven ability to train and develop new team members, ensuring a smooth onboarding process and improved productivity.

Education

Bachelor of Science in Semiconductor Manufacturing

September 2015

Skills

- Photolithography

- Etching

- Thin Film Deposition

- Diffusion

- Ion Implantation

- Chemical Mechanical Polishing

Work Experience

Wafer Fabrication Operator

- Troubleshooted and resolved equipment malfunctions, minimizing downtime.

- Adhered to cleanroom protocols and maintained a contamination-free environment.

- Worked collaboratively with engineers and technicians to optimize processes and improve yield.

- Contributed to yield improvement initiatives, reducing defects and increasing production throughput.

Wafer Fabrication Operator

- Proficiently operated and maintained wafer fabrication equipment, including lithography, etching, and deposition systems.

- Conducted routine inspections and preventive maintenance to ensure optimal equipment performance.

- Monitored process parameters and made adjustments to maintain strict quality specifications.

- Utilized metrology tools to characterize wafers and ensure product quality.

Accomplishments

- Consistently exceeded production targets by 12%, resulting in increased wafer yields and reduced manufacturing costs.

- Developed an innovative cleaning process that reduced particle contamination by 20%, improving wafer quality and enhancing device performance.

- Implemented a predictive maintenance schedule, which reduced equipment downtime by 15% and increased wafer fabrication efficiency.

- Developed and implemented a training program for new operators, ensuring a smooth onboarding process and improved productivity.

- Received recognition for exceptional safety practices, maintaining a clean and compliant work environment.

Certificates

- Certified Wafer Fabrication Operator (CWFO)

- Cleanroom Certification

- ESD Control Certification

- Hazardous Materials Handling Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Fabrication Operator

- Highlight your technical skills and expertise in wafer fabrication processes, such as photolithography, etching, and thin film deposition.

- Quantify your accomplishments with specific metrics, such as increased yields, reduced contamination, or improved efficiency.

- Emphasize your commitment to safety and compliance, and highlight any relevant certifications or training.

- Showcase your communication and teamwork skills, as well as your ability to train and mentor new employees.

Essential Experience Highlights for a Strong Wafer Fabrication Operator Resume

- Operate and monitor wafer fabrication equipment, including photolithography, etching, and thin film deposition systems.

- Control process parameters to ensure wafer quality and yield.

- Troubleshoot and resolve equipment issues to minimize downtime and maintain production efficiency.

- Adhere to safety regulations, maintain a clean work environment, and follow proper handling procedures.

- Participate in continuous improvement initiatives to optimize processes and reduce costs.

- Collaborate with engineers and technicians to support product development and process optimization.

Frequently Asked Questions (FAQ’s) For Wafer Fabrication Operator

What are the key responsibilities of a Wafer Fabrication Operator?

Wafer Fabrication Operators are responsible for operating and monitoring wafer fabrication equipment, controlling process parameters, troubleshooting issues, adhering to safety regulations, and participating in continuous improvement initiatives.

What skills are required to be a successful Wafer Fabrication Operator?

Successful Wafer Fabrication Operators possess strong technical skills in photolithography, etching, and other fabrication techniques, as well as a commitment to safety and quality.

What is the work environment like for a Wafer Fabrication Operator?

Wafer Fabrication Operators typically work in cleanroom environments, following strict safety protocols to minimize contamination.

What are the career advancement opportunities for a Wafer Fabrication Operator?

With experience and additional training, Wafer Fabrication Operators can advance to roles such as Process Engineer, Production Supervisor, or Quality Control Manager.

What is the salary range for a Wafer Fabrication Operator?

The salary range for a Wafer Fabrication Operator can vary depending on experience, location, and company size, but typically falls between $30,000 and $60,000 per year.

What are the educational requirements for a Wafer Fabrication Operator?

Most Wafer Fabrication Operators hold a high school diploma or equivalent, with some employers preferring candidates with an associate’s degree or higher in semiconductor manufacturing.