Are you a seasoned Wafer Fabrication Technician seeking a new career path? Discover our professionally built Wafer Fabrication Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

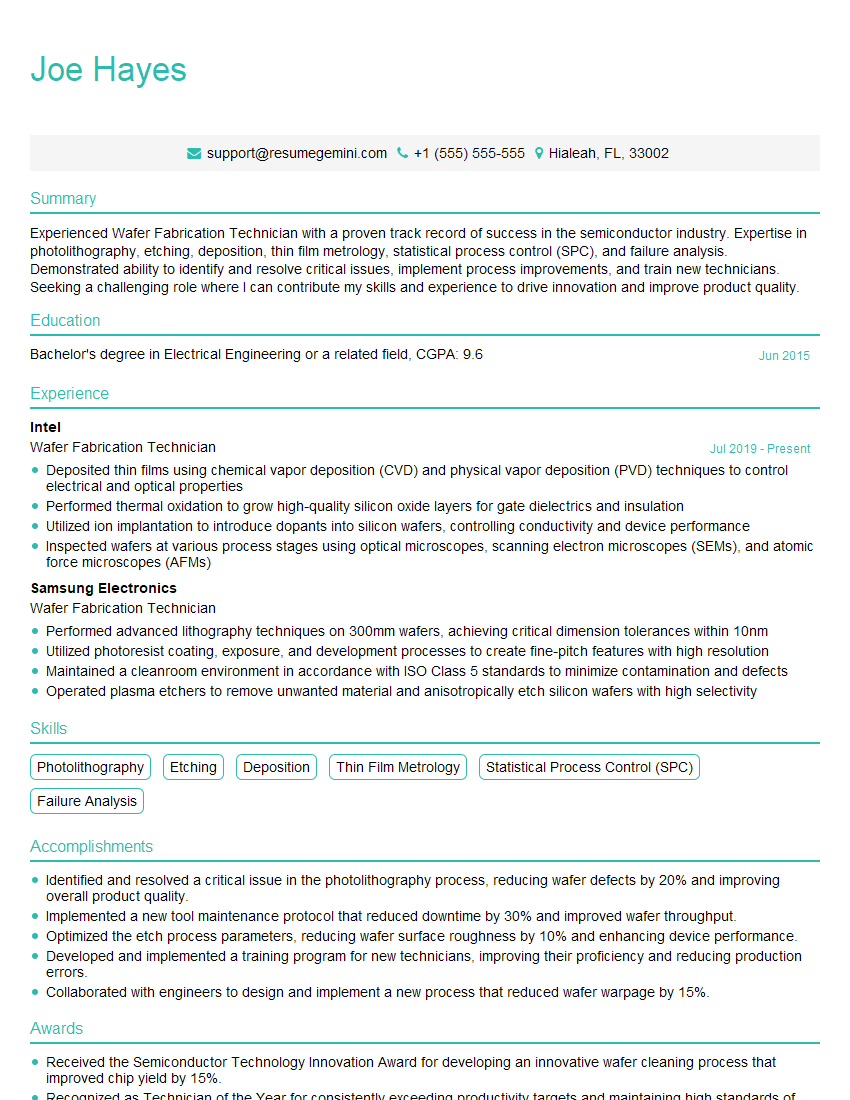

Joe Hayes

Wafer Fabrication Technician

Summary

Experienced Wafer Fabrication Technician with a proven track record of success in the semiconductor industry. Expertise in photolithography, etching, deposition, thin film metrology, statistical process control (SPC), and failure analysis. Demonstrated ability to identify and resolve critical issues, implement process improvements, and train new technicians. Seeking a challenging role where I can contribute my skills and experience to drive innovation and improve product quality.

Education

Bachelor’s degree in Electrical Engineering or a related field

June 2015

Skills

- Photolithography

- Etching

- Deposition

- Thin Film Metrology

- Statistical Process Control (SPC)

- Failure Analysis

Work Experience

Wafer Fabrication Technician

- Deposited thin films using chemical vapor deposition (CVD) and physical vapor deposition (PVD) techniques to control electrical and optical properties

- Performed thermal oxidation to grow high-quality silicon oxide layers for gate dielectrics and insulation

- Utilized ion implantation to introduce dopants into silicon wafers, controlling conductivity and device performance

- Inspected wafers at various process stages using optical microscopes, scanning electron microscopes (SEMs), and atomic force microscopes (AFMs)

Wafer Fabrication Technician

- Performed advanced lithography techniques on 300mm wafers, achieving critical dimension tolerances within 10nm

- Utilized photoresist coating, exposure, and development processes to create fine-pitch features with high resolution

- Maintained a cleanroom environment in accordance with ISO Class 5 standards to minimize contamination and defects

- Operated plasma etchers to remove unwanted material and anisotropically etch silicon wafers with high selectivity

Accomplishments

- Identified and resolved a critical issue in the photolithography process, reducing wafer defects by 20% and improving overall product quality.

- Implemented a new tool maintenance protocol that reduced downtime by 30% and improved wafer throughput.

- Optimized the etch process parameters, reducing wafer surface roughness by 10% and enhancing device performance.

- Developed and implemented a training program for new technicians, improving their proficiency and reducing production errors.

- Collaborated with engineers to design and implement a new process that reduced wafer warpage by 15%.

Awards

- Received the Semiconductor Technology Innovation Award for developing an innovative wafer cleaning process that improved chip yield by 15%.

- Recognized as Technician of the Year for consistently exceeding productivity targets and maintaining high standards of process control.

- Received a Safety Excellence Award for exceptional contributions to maintaining a safe and compliant work environment.

- Recognized as a Process Champion for expertise in troubleshooting and resolving complex technical issues.

Certificates

- Certified Wafer Fab Technician (CWFT)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Fabrication Technician

- Highlight your experience and skills in the semiconductor industry.

- Quantify your accomplishments with specific metrics, such as reducing wafer defects or improving yield.

- Demonstrate your ability to work independently and as part of a team.

- Be prepared to discuss your knowledge of wafer fabrication processes and equipment.

Essential Experience Highlights for a Strong Wafer Fabrication Technician Resume

- Operate and maintain wafer fabrication equipment, including photolithography, etching, and deposition systems

- Monitor and control process parameters to ensure wafer quality and yield

- Troubleshoot and resolve process issues, including defects, contamination, and yield loss

- Perform statistical process control (SPC) to monitor and improve process performance

- Collaborate with engineers and other team members to develop and implement process improvements

- Train and mentor new technicians

- Maintain a clean and organized work environment

Frequently Asked Questions (FAQ’s) For Wafer Fabrication Technician

What is a Wafer Fabrication Technician?

A Wafer Fabrication Technician is responsible for operating and maintaining the equipment used to manufacture semiconductor wafers. They monitor and control process parameters, troubleshoot and resolve process issues, and perform statistical process control (SPC) to ensure wafer quality and yield.

What are the qualifications for a Wafer Fabrication Technician?

A Wafer Fabrication Technician typically has a bachelor’s degree in electrical engineering or a related field, and experience in the semiconductor industry. They should also have a strong understanding of wafer fabrication processes and equipment.

What are the responsibilities of a Wafer Fabrication Technician?

The responsibilities of a Wafer Fabrication Technician include operating and maintaining wafer fabrication equipment, monitoring and controlling process parameters, troubleshooting and resolving process issues, and performing statistical process control (SPC). They also collaborate with engineers and other team members to develop and implement process improvements and train new technicians.

What are the skills required for a Wafer Fabrication Technician?

A Wafer Fabrication Technician should have a strong understanding of wafer fabrication processes and equipment, as well as experience in operating and maintaining semiconductor manufacturing equipment. They should also have good problem-solving skills, be able to work independently and as part of a team, and be able to follow instructions carefully.

What is the career outlook for a Wafer Fabrication Technician?

The career outlook for a Wafer Fabrication Technician is expected to be good over the next few years. The demand for semiconductors is growing, and this is expected to lead to increased demand for Wafer Fabrication Technicians.

What is the average salary for a Wafer Fabrication Technician?

The average salary for a Wafer Fabrication Technician is around $60,000 per year.