Are you a seasoned Wafer Fabricator seeking a new career path? Discover our professionally built Wafer Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

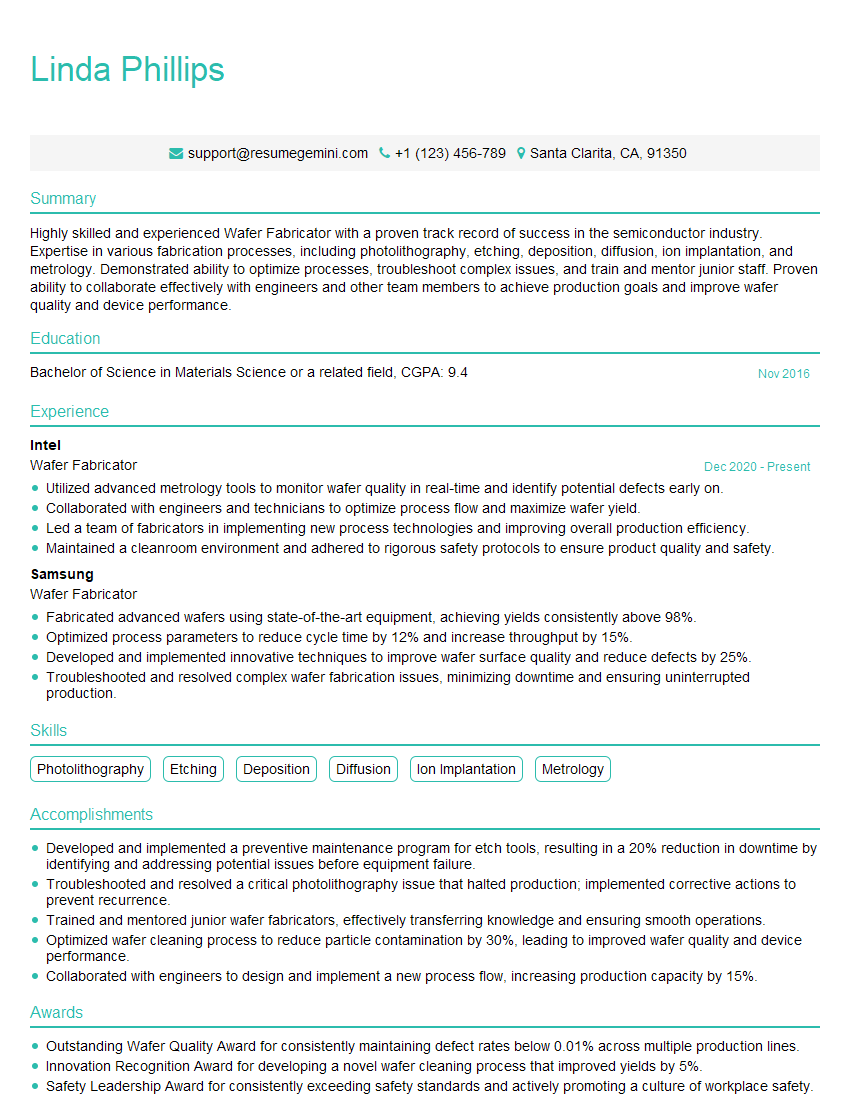

Linda Phillips

Wafer Fabricator

Summary

Highly skilled and experienced Wafer Fabricator with a proven track record of success in the semiconductor industry. Expertise in various fabrication processes, including photolithography, etching, deposition, diffusion, ion implantation, and metrology. Demonstrated ability to optimize processes, troubleshoot complex issues, and train and mentor junior staff. Proven ability to collaborate effectively with engineers and other team members to achieve production goals and improve wafer quality and device performance.

Education

Bachelor of Science in Materials Science or a related field

November 2016

Skills

- Photolithography

- Etching

- Deposition

- Diffusion

- Ion Implantation

- Metrology

Work Experience

Wafer Fabricator

- Utilized advanced metrology tools to monitor wafer quality in real-time and identify potential defects early on.

- Collaborated with engineers and technicians to optimize process flow and maximize wafer yield.

- Led a team of fabricators in implementing new process technologies and improving overall production efficiency.

- Maintained a cleanroom environment and adhered to rigorous safety protocols to ensure product quality and safety.

Wafer Fabricator

- Fabricated advanced wafers using state-of-the-art equipment, achieving yields consistently above 98%.

- Optimized process parameters to reduce cycle time by 12% and increase throughput by 15%.

- Developed and implemented innovative techniques to improve wafer surface quality and reduce defects by 25%.

- Troubleshooted and resolved complex wafer fabrication issues, minimizing downtime and ensuring uninterrupted production.

Accomplishments

- Developed and implemented a preventive maintenance program for etch tools, resulting in a 20% reduction in downtime by identifying and addressing potential issues before equipment failure.

- Troubleshooted and resolved a critical photolithography issue that halted production; implemented corrective actions to prevent recurrence.

- Trained and mentored junior wafer fabricators, effectively transferring knowledge and ensuring smooth operations.

- Optimized wafer cleaning process to reduce particle contamination by 30%, leading to improved wafer quality and device performance.

- Collaborated with engineers to design and implement a new process flow, increasing production capacity by 15%.

Awards

- Outstanding Wafer Quality Award for consistently maintaining defect rates below 0.01% across multiple production lines.

- Innovation Recognition Award for developing a novel wafer cleaning process that improved yields by 5%.

- Safety Leadership Award for consistently exceeding safety standards and actively promoting a culture of workplace safety.

- Excellence in Process Control Award for consistently meeting and exceeding critical dimension (CD) and overlay specifications.

Certificates

- Certified Wafer Fabricator (CWF)

- SMIF Compliance Certification

- OSHA Safety Certification

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wafer Fabricator

- Showcase your technical expertise and experience in semiconductor fabrication processes.

- Quantify your accomplishments with specific metrics and results, such as reduced downtime, improved yield, or increased production capacity.

- Highlight your troubleshooting and problem-solving skills, demonstrating your ability to resolve complex production issues.

- Emphasize your training and mentoring experience, indicating your ability to effectively transfer knowledge and develop junior staff.

- Include keywords relevant to the semiconductor industry and wafer fabrication processes to enhance your resume’s visibility to potential employers.

Essential Experience Highlights for a Strong Wafer Fabricator Resume

- Develop and implement preventive maintenance programs to minimize equipment downtime

- Troubleshoot and resolve critical production issues to ensure smooth operations

- Train and mentor junior wafer fabricators to transfer knowledge and ensure operational efficiency

- Optimize fabrication processes to improve wafer quality, device performance, and production capacity

- Collaborate with engineers to design and implement new process flows to enhance productivity

- Conduct regular quality control inspections to ensure adherence to specifications and standards

- Maintain a clean and organized work environment to minimize contamination and defects

- Stay abreast of industry best practices and emerging technologies to continuously improve fabrication processes

Frequently Asked Questions (FAQ’s) For Wafer Fabricator

What is the role of a wafer fabricator?

A wafer fabricator is responsible for producing semiconductor wafers, which are used in the manufacturing of electronic devices such as transistors, integrated circuits, and solar cells. They operate and maintain fabrication equipment, troubleshoot and resolve production issues, and optimize processes to ensure the quality and yield of the wafers.

What skills are essential for a wafer fabricator?

Essential skills for a wafer fabricator include expertise in semiconductor fabrication processes, troubleshooting and problem-solving abilities, knowledge of metrology techniques, and a strong understanding of cleanroom procedures. They should also possess good communication and teamwork skills, as they often collaborate with engineers and other team members.

What is the career path for a wafer fabricator?

With experience and additional training, wafer fabricators can advance to roles such as process engineer, quality control manager, or production supervisor. They may also pursue specialized roles in areas such as lithography, etching, or deposition.

What are the job prospects for wafer fabricators?

The job outlook for wafer fabricators is expected to grow in the coming years due to the increasing demand for semiconductors in various electronic devices. The semiconductor industry is constantly evolving, and wafer fabricators who stay abreast of emerging technologies and best practices will have the best job prospects.

How can I prepare for a career as a wafer fabricator?

To prepare for a career as a wafer fabricator, consider pursuing a degree in materials science, electrical engineering, or a related field. Gain hands-on experience through internships or research projects in the semiconductor industry. Additionally, stay updated on the latest advancements in semiconductor fabrication technologies and cleanroom practices.