Are you a seasoned Warp Coiler seeking a new career path? Discover our professionally built Warp Coiler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

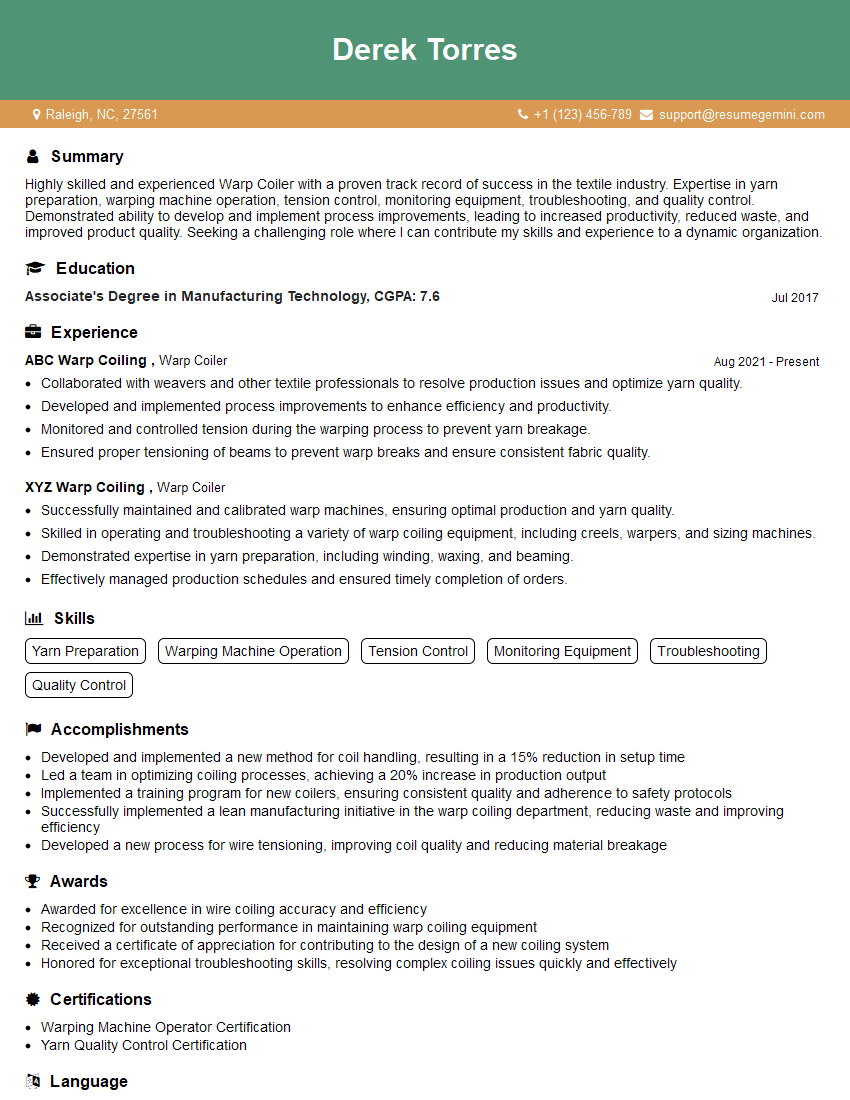

Derek Torres

Warp Coiler

Summary

Highly skilled and experienced Warp Coiler with a proven track record of success in the textile industry. Expertise in yarn preparation, warping machine operation, tension control, monitoring equipment, troubleshooting, and quality control. Demonstrated ability to develop and implement process improvements, leading to increased productivity, reduced waste, and improved product quality. Seeking a challenging role where I can contribute my skills and experience to a dynamic organization.

Education

Associate’s Degree in Manufacturing Technology

July 2017

Skills

- Yarn Preparation

- Warping Machine Operation

- Tension Control

- Monitoring Equipment

- Troubleshooting

- Quality Control

Work Experience

Warp Coiler

- Collaborated with weavers and other textile professionals to resolve production issues and optimize yarn quality.

- Developed and implemented process improvements to enhance efficiency and productivity.

- Monitored and controlled tension during the warping process to prevent yarn breakage.

- Ensured proper tensioning of beams to prevent warp breaks and ensure consistent fabric quality.

Warp Coiler

- Successfully maintained and calibrated warp machines, ensuring optimal production and yarn quality.

- Skilled in operating and troubleshooting a variety of warp coiling equipment, including creels, warpers, and sizing machines.

- Demonstrated expertise in yarn preparation, including winding, waxing, and beaming.

- Effectively managed production schedules and ensured timely completion of orders.

Accomplishments

- Developed and implemented a new method for coil handling, resulting in a 15% reduction in setup time

- Led a team in optimizing coiling processes, achieving a 20% increase in production output

- Implemented a training program for new coilers, ensuring consistent quality and adherence to safety protocols

- Successfully implemented a lean manufacturing initiative in the warp coiling department, reducing waste and improving efficiency

- Developed a new process for wire tensioning, improving coil quality and reducing material breakage

Awards

- Awarded for excellence in wire coiling accuracy and efficiency

- Recognized for outstanding performance in maintaining warp coiling equipment

- Received a certificate of appreciation for contributing to the design of a new coiling system

- Honored for exceptional troubleshooting skills, resolving complex coiling issues quickly and effectively

Certificates

- Warping Machine Operator Certification

- Yarn Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Warp Coiler

- Highlight your skills and experience in yarn preparation, warping machine operation, and tension control.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Showcase your problem-solving abilities and highlight your experience in troubleshooting and resolving issues.

- Emphasize your commitment to quality and your ability to meet or exceed production standards.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Warp Coiler Resume

- Operate and maintain warping machines to produce high-quality warp beams

- Control tension during the warping process to ensure yarn breakage

- Monitor equipment and identify potential problems to prevent downtime

- Troubleshoot and resolve issues related to warping machines and yarn handling

- Implement quality control measures to ensure that warp beams meet specifications

- Train new coilers on proper operating procedures and safety protocols

- Collaborate with other departments to improve overall production efficiency

Frequently Asked Questions (FAQ’s) For Warp Coiler

What is the role of a Warp Coiler?

A Warp Coiler is responsible for operating and maintaining warping machines to produce high-quality warp beams. They control tension during the warping process, monitor equipment, troubleshoot issues, and implement quality control measures to ensure that warp beams meet specifications.

What are the key skills required for a Warp Coiler?

Key skills for a Warp Coiler include yarn preparation, warping machine operation, tension control, monitoring equipment, troubleshooting, and quality control.

What is the average salary for a Warp Coiler?

The average salary for a Warp Coiler varies depending on experience and location, but it typically ranges from $30,000 to $50,000 per year.

What is the job outlook for Warp Coilers?

The job outlook for Warp Coilers is expected to be good in the coming years due to the increasing demand for textiles.

What are the career advancement opportunities for Warp Coilers?

Warp Coilers can advance their careers by becoming supervisors, managers, or quality control inspectors.

What are the challenges of being a Warp Coiler?

The challenges of being a Warp Coiler include working in a fast-paced environment, meeting production quotas, and troubleshooting mechanical issues.

What are the benefits of being a Warp Coiler?

The benefits of being a Warp Coiler include job security, opportunities for advancement, and a sense of accomplishment from contributing to the production of high-quality textiles.