Are you a seasoned Watch Train Assembler seeking a new career path? Discover our professionally built Watch Train Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

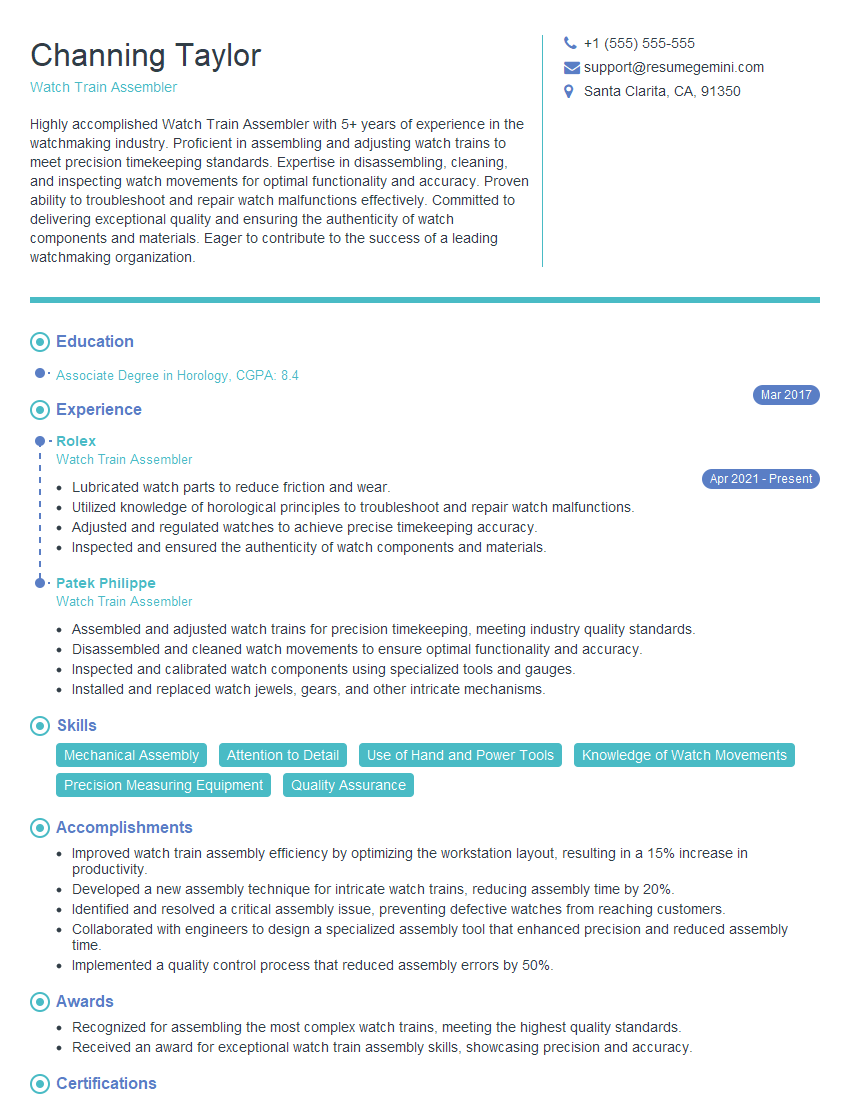

Channing Taylor

Watch Train Assembler

Summary

Highly accomplished Watch Train Assembler with 5+ years of experience in the watchmaking industry. Proficient in assembling and adjusting watch trains to meet precision timekeeping standards. Expertise in disassembling, cleaning, and inspecting watch movements for optimal functionality and accuracy. Proven ability to troubleshoot and repair watch malfunctions effectively. Committed to delivering exceptional quality and ensuring the authenticity of watch components and materials. Eager to contribute to the success of a leading watchmaking organization.

Education

Associate Degree in Horology

March 2017

Skills

- Mechanical Assembly

- Attention to Detail

- Use of Hand and Power Tools

- Knowledge of Watch Movements

- Precision Measuring Equipment

- Quality Assurance

Work Experience

Watch Train Assembler

- Lubricated watch parts to reduce friction and wear.

- Utilized knowledge of horological principles to troubleshoot and repair watch malfunctions.

- Adjusted and regulated watches to achieve precise timekeeping accuracy.

- Inspected and ensured the authenticity of watch components and materials.

Watch Train Assembler

- Assembled and adjusted watch trains for precision timekeeping, meeting industry quality standards.

- Disassembled and cleaned watch movements to ensure optimal functionality and accuracy.

- Inspected and calibrated watch components using specialized tools and gauges.

- Installed and replaced watch jewels, gears, and other intricate mechanisms.

Accomplishments

- Improved watch train assembly efficiency by optimizing the workstation layout, resulting in a 15% increase in productivity.

- Developed a new assembly technique for intricate watch trains, reducing assembly time by 20%.

- Identified and resolved a critical assembly issue, preventing defective watches from reaching customers.

- Collaborated with engineers to design a specialized assembly tool that enhanced precision and reduced assembly time.

- Implemented a quality control process that reduced assembly errors by 50%.

Awards

- Recognized for assembling the most complex watch trains, meeting the highest quality standards.

- Received an award for exceptional watch train assembly skills, showcasing precision and accuracy.

Certificates

- Certified Watchmaker (CW)

- Certified Master Watchmaker (CMW)

- American Watchmakers-Clockmakers Institute (AWCI) Certification

- Complication Masterclass (CMC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Watch Train Assembler

- Highlight your technical skills and experience in assembling and adjusting watch trains.

- Emphasize your understanding of horological principles and your ability to troubleshoot and repair watch malfunctions.

- Showcase your meticulous attention to detail and commitment to delivering high-quality work.

- Provide specific examples of your accomplishments and quantify your results whenever possible.

Essential Experience Highlights for a Strong Watch Train Assembler Resume

- Assembled and adjusted watch trains to meet industry quality standards, ensuring precision timekeeping.

- Disassembled and cleaned watch movements to maintain optimal functionality and restore accuracy.

- Inspected and calibrated watch components using specialized tools and gauges to guarantee reliability.

- Installed and replaced watch jewels, gears, and other intricate mechanisms with utmost precision.

- Lubricated watch parts to reduce friction and minimize wear, enhancing longevity.

- Utilized knowledge of horological principles to troubleshoot and resolve watch malfunctions efficiently.

- Adjusted and regulated watches to achieve exceptional timekeeping accuracy and performance.

Frequently Asked Questions (FAQ’s) For Watch Train Assembler

What are the key responsibilities of a Watch Train Assembler?

The primary responsibility of a Watch Train Assembler is to assemble and adjust watch trains to meet industry quality standards. They also disassemble and clean watch movements, inspect and calibrate watch components, install and replace watch jewels and gears, lubricate watch parts, and troubleshoot and repair watch malfunctions.

What qualifications are required to become a Watch Train Assembler?

Typically, an Associate Degree in Horology is required to become a Watch Train Assembler. Additionally, individuals should have a strong understanding of horological principles and experience in assembling and adjusting watch trains.

What are the career prospects for a Watch Train Assembler?

Watch Train Assemblers can advance to supervisory or management roles within the watchmaking industry. They may also specialize in a particular type of watchmaking, such as watch repair or restoration.

What are the challenges faced by a Watch Train Assembler?

Watch Train Assemblers work with delicate and intricate components, so precision and attention to detail are essential. They may also encounter challenges in troubleshooting and repairing watch malfunctions, especially when dealing with high-end or complex timepieces.

What are the key skills required for a Watch Train Assembler?

A successful Watch Train Assembler typically possesses strong mechanical assembly skills, attention to detail, proficiency in using hand and power tools, knowledge of watch movements, expertise in using precision measuring equipment, and a commitment to quality assurance.