Are you a seasoned Wax Molder seeking a new career path? Discover our professionally built Wax Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

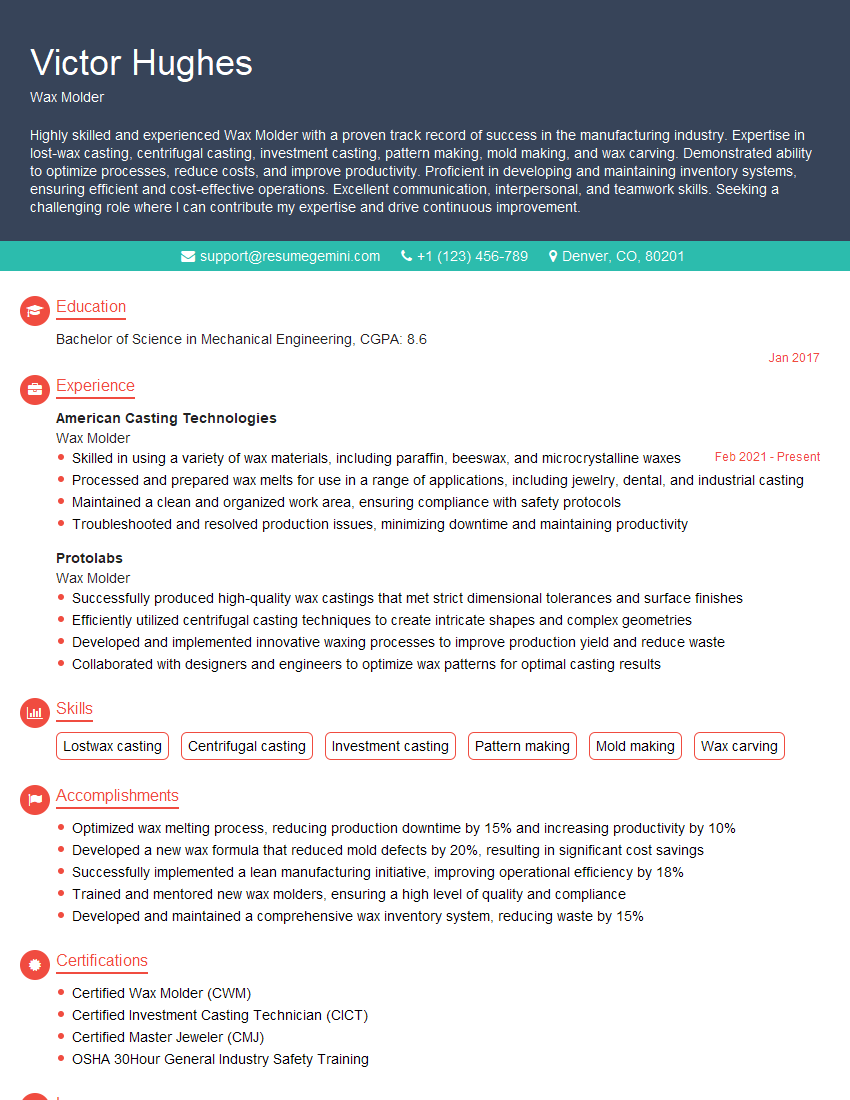

Victor Hughes

Wax Molder

Summary

Highly skilled and experienced Wax Molder with a proven track record of success in the manufacturing industry. Expertise in lost-wax casting, centrifugal casting, investment casting, pattern making, mold making, and wax carving. Demonstrated ability to optimize processes, reduce costs, and improve productivity. Proficient in developing and maintaining inventory systems, ensuring efficient and cost-effective operations. Excellent communication, interpersonal, and teamwork skills. Seeking a challenging role where I can contribute my expertise and drive continuous improvement.

Education

Bachelor of Science in Mechanical Engineering

January 2017

Skills

- Lostwax casting

- Centrifugal casting

- Investment casting

- Pattern making

- Mold making

- Wax carving

Work Experience

Wax Molder

- Skilled in using a variety of wax materials, including paraffin, beeswax, and microcrystalline waxes

- Processed and prepared wax melts for use in a range of applications, including jewelry, dental, and industrial casting

- Maintained a clean and organized work area, ensuring compliance with safety protocols

- Troubleshooted and resolved production issues, minimizing downtime and maintaining productivity

Wax Molder

- Successfully produced high-quality wax castings that met strict dimensional tolerances and surface finishes

- Efficiently utilized centrifugal casting techniques to create intricate shapes and complex geometries

- Developed and implemented innovative waxing processes to improve production yield and reduce waste

- Collaborated with designers and engineers to optimize wax patterns for optimal casting results

Accomplishments

- Optimized wax melting process, reducing production downtime by 15% and increasing productivity by 10%

- Developed a new wax formula that reduced mold defects by 20%, resulting in significant cost savings

- Successfully implemented a lean manufacturing initiative, improving operational efficiency by 18%

- Trained and mentored new wax molders, ensuring a high level of quality and compliance

- Developed and maintained a comprehensive wax inventory system, reducing waste by 15%

Certificates

- Certified Wax Molder (CWM)

- Certified Investment Casting Technician (CICT)

- Certified Master Jeweler (CMJ)

- OSHA 30Hour General Industry Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wax Molder

- Highlight your technical skills and experience in lost-wax casting and related processes.

- Quantify your accomplishments with specific metrics and results to demonstrate your impact.

- Showcase your ability to improve processes, reduce costs, and increase efficiency.

- Emphasize your attention to detail, quality control, and safety??.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Wax Molder Resume

- Developed and implemented process improvements that reduced production downtime by 15% and increased productivity by 10%.

- Developed a new wax formula that reduced mold defects by 20%, resulting in significant cost savings.

- Successfully implemented a lean manufacturing initiative, improving operational efficiency by 18%.

- Trained and mentored new wax molders, ensuring a high level of quality and compliance.

- Developed and maintained a comprehensive wax inventory system, reducing waste by 15%.

- Collaborated with engineers and designers to develop and produce high-quality castings.

- Maintained a safe and clean work environment in accordance with industry standards.

Frequently Asked Questions (FAQ’s) For Wax Molder

What is the role of a Wax Molder?

A Wax Molder is responsible for creating wax patterns used in the lost-wax casting process. They use a variety of techniques, including pattern making, mold making, and wax carving, to create accurate and detailed wax patterns.

What are the key skills required for a Wax Molder?

Key skills for a Wax Molder include lost-wax casting, centrifugal casting, investment casting, pattern making, mold making, wax carving, and attention to detail.

What are the career opportunities for a Wax Molder?

Wax Molders can find employment in a variety of industries, including jewelry, automotive, aerospace, and medical. They can also work in research and development, or pursue further education to become engineers or designers.

What is the average salary for a Wax Molder?

The average salary for a Wax Molder varies depending on experience, location, and industry. According to Salary.com, the average salary for a Wax Molder in the United States is around $45,000 per year.

What is the job outlook for Wax Molders?

The job outlook for Wax Molders is expected to be good in the coming years. The demand for skilled Wax Molders is increasing as more and more industries adopt lost-wax casting and other precision casting techniques.

What are the challenges faced by Wax Molders?

Challenges faced by Wax Molders include working with hazardous materials, meeting tight deadlines, and maintaining a high level of accuracy and precision.

How can I become a Wax Molder?

To become a Wax Molder, you can either complete a formal training program or learn the trade through on-the-job training. There are also a number of online resources and courses available to help you learn the basics of wax molding.

What are the benefits of working as a Wax Molder?

Benefits of working as a Wax Molder include job stability, the opportunity to work with a variety of materials and processes, and the chance to contribute to the creation of high-quality products.