Are you a seasoned Welder-Fabricator seeking a new career path? Discover our professionally built Welder-Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

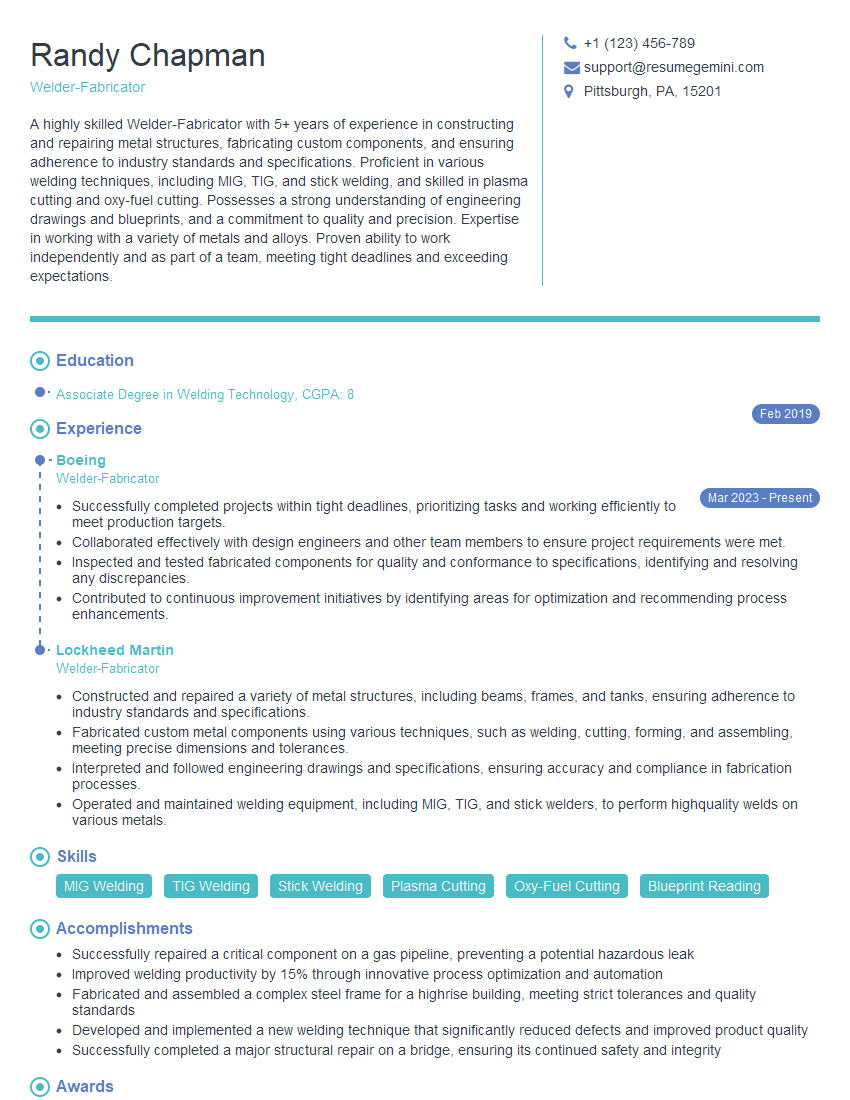

Randy Chapman

Welder-Fabricator

Summary

A highly skilled Welder-Fabricator with 5+ years of experience in constructing and repairing metal structures, fabricating custom components, and ensuring adherence to industry standards and specifications. Proficient in various welding techniques, including MIG, TIG, and stick welding, and skilled in plasma cutting and oxy-fuel cutting. Possesses a strong understanding of engineering drawings and blueprints, and a commitment to quality and precision. Expertise in working with a variety of metals and alloys. Proven ability to work independently and as part of a team, meeting tight deadlines and exceeding expectations.

Education

Associate Degree in Welding Technology

February 2019

Skills

- MIG Welding

- TIG Welding

- Stick Welding

- Plasma Cutting

- Oxy-Fuel Cutting

- Blueprint Reading

Work Experience

Welder-Fabricator

- Successfully completed projects within tight deadlines, prioritizing tasks and working efficiently to meet production targets.

- Collaborated effectively with design engineers and other team members to ensure project requirements were met.

- Inspected and tested fabricated components for quality and conformance to specifications, identifying and resolving any discrepancies.

- Contributed to continuous improvement initiatives by identifying areas for optimization and recommending process enhancements.

Welder-Fabricator

- Constructed and repaired a variety of metal structures, including beams, frames, and tanks, ensuring adherence to industry standards and specifications.

- Fabricated custom metal components using various techniques, such as welding, cutting, forming, and assembling, meeting precise dimensions and tolerances.

- Interpreted and followed engineering drawings and specifications, ensuring accuracy and compliance in fabrication processes.

- Operated and maintained welding equipment, including MIG, TIG, and stick welders, to perform highquality welds on various metals.

Accomplishments

- Successfully repaired a critical component on a gas pipeline, preventing a potential hazardous leak

- Improved welding productivity by 15% through innovative process optimization and automation

- Fabricated and assembled a complex steel frame for a highrise building, meeting strict tolerances and quality standards

- Developed and implemented a new welding technique that significantly reduced defects and improved product quality

- Successfully completed a major structural repair on a bridge, ensuring its continued safety and integrity

Awards

- Awarded Welder of the Year in the National Welding Competition

- Recognized for exceptional craftsmanship and attention to detail in the fabrication of custom metal structures

- Received the Excellence in Welding award from the American Welding Society

- Won the Best Welded Fabrication award at the International Welding Exhibition

Certificates

- AWS Certified Welder

- ASME Certified Welder

- OSHA 30-Hour Safety Training

- NCCER Welding Curriculum

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Welder-Fabricator

- Highlight your welding skills and experience in different welding techniques such as MIG, TIG, and stick welding.

- Emphasize your ability to fabricate custom metal components and work with various metals and alloys.

- Showcase your knowledge of engineering drawings and blueprints, as well as your attention to detail and precision.

- Include any certifications or training programs that demonstrate your expertise in welding and fabrication.

Essential Experience Highlights for a Strong Welder-Fabricator Resume

- Fabricate and repair metal structures, including beams, frames, and tanks, ensuring adherence to industry standards and specifications.

- Fabricate custom metal components using various techniques, such as welding, cutting, forming, and assembling, meeting precise dimensions and tolerances.

- Interpret and follow engineering drawings and specifications, ensuring accuracy and compliance in fabrication processes.

- Operate and maintain welding equipment, including MIG, TIG, and stick welders, to perform high-quality welds on various metals.

- Inspect and test fabricated components for quality and conformance to specifications, identifying and resolving any discrepancies.

- Collaborate effectively with design engineers and other team members to ensure project requirements were met.

- Contribute to continuous improvement initiatives by identifying areas for optimization and recommending process enhancements.

Frequently Asked Questions (FAQ’s) For Welder-Fabricator

What are the essential skills for a Welder-Fabricator?

Essential skills for a Welder-Fabricator include proficiency in various welding techniques, such as MIG, TIG, and stick welding, as well as plasma cutting and oxy-fuel cutting. Knowledge of engineering drawings and blueprints, along with a strong understanding of metal properties and fabrication processes, is also crucial.

What are the primary responsibilities of a Welder-Fabricator?

Key responsibilities of a Welder-Fabricator involve fabricating and repairing metal structures, custom metal components, and adhering to industry standards and specifications. They interpret engineering drawings, operate welding equipment, inspect and test components, collaborate with engineers, and contribute to continuous improvement initiatives.

What industries employ Welder-Fabricators?

Welder-Fabricators are employed in various industries, including construction, manufacturing, shipbuilding, automotive, and aerospace. They work on projects ranging from small repairs to large-scale fabrication of complex structures.

What is the average salary for a Welder-Fabricator?

The average salary for a Welder-Fabricator varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for welders, cutters, solderers, and brazers was $47,610 in May 2021.

What is the job outlook for Welder-Fabricators?

The job outlook for Welder-Fabricators is expected to be positive in the coming years. The aging workforce and increasing demand for skilled welders in various industries contribute to this growth.

What are the educational requirements for a Welder-Fabricator?

Educational requirements for a Welder-Fabricator typically include an associate degree in welding technology or a related field. Additionally, many Welder-Fabricators complete apprenticeships or on-the-job training programs to gain practical experience.

What are the career advancement opportunities for a Welder-Fabricator?

Career advancement opportunities for a Welder-Fabricator can include promotions to lead welder, welding supervisor, welding inspector, or welding engineer. With experience and additional training, Welder-Fabricators can also start their own welding businesses.