Are you a seasoned Welding Pantograph Operator seeking a new career path? Discover our professionally built Welding Pantograph Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

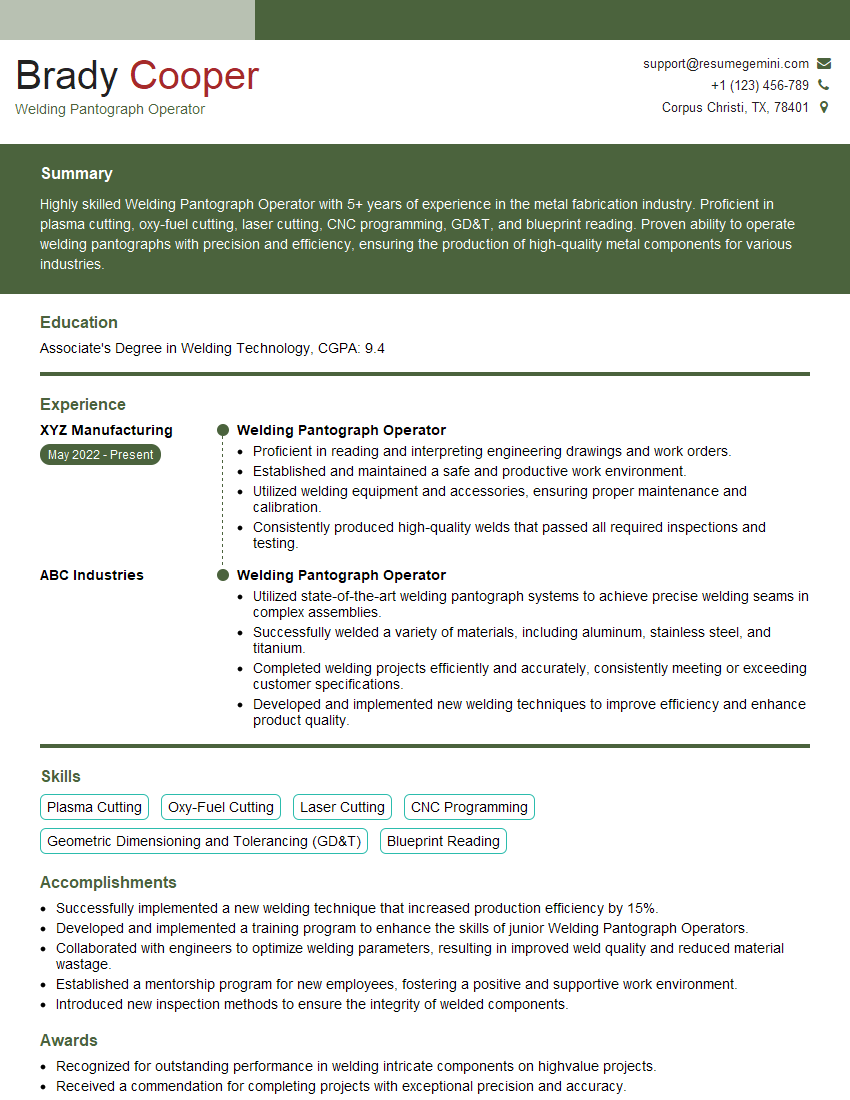

Brady Cooper

Welding Pantograph Operator

Summary

Highly skilled Welding Pantograph Operator with 5+ years of experience in the metal fabrication industry. Proficient in plasma cutting, oxy-fuel cutting, laser cutting, CNC programming, GD&T, and blueprint reading. Proven ability to operate welding pantographs with precision and efficiency, ensuring the production of high-quality metal components for various industries.

Education

Associate’s Degree in Welding Technology

April 2018

Skills

- Plasma Cutting

- Oxy-Fuel Cutting

- Laser Cutting

- CNC Programming

- Geometric Dimensioning and Tolerancing (GD&T)

- Blueprint Reading

Work Experience

Welding Pantograph Operator

- Proficient in reading and interpreting engineering drawings and work orders.

- Established and maintained a safe and productive work environment.

- Utilized welding equipment and accessories, ensuring proper maintenance and calibration.

- Consistently produced high-quality welds that passed all required inspections and testing.

Welding Pantograph Operator

- Utilized state-of-the-art welding pantograph systems to achieve precise welding seams in complex assemblies.

- Successfully welded a variety of materials, including aluminum, stainless steel, and titanium.

- Completed welding projects efficiently and accurately, consistently meeting or exceeding customer specifications.

- Developed and implemented new welding techniques to improve efficiency and enhance product quality.

Accomplishments

- Successfully implemented a new welding technique that increased production efficiency by 15%.

- Developed and implemented a training program to enhance the skills of junior Welding Pantograph Operators.

- Collaborated with engineers to optimize welding parameters, resulting in improved weld quality and reduced material wastage.

- Established a mentorship program for new employees, fostering a positive and supportive work environment.

- Introduced new inspection methods to ensure the integrity of welded components.

Awards

- Recognized for outstanding performance in welding intricate components on highvalue projects.

- Received a commendation for completing projects with exceptional precision and accuracy.

- Awarded a safety accolade for implementing innovative measures to improve workplace safety.

- Won a regional competition for producing the highest quality weldments.

Certificates

- AWS Certified Welder

- ASME Code Welding Certification

- ISO 9001:2015 Certified

- OSHA 30-Hour Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Welding Pantograph Operator

- Highlight your experience in operating welding pantographs and proficiency in cutting techniques.

- Quantify your accomplishments with specific metrics whenever possible, such as increased productivity or reduced scrap rates.

- Include keywords relevant to the job, such as plasma cutting, oxy-fuel cutting, laser cutting, CNC programming, GD&T, and blueprint reading.

- Proofread your resume carefully for errors in grammar, spelling, and formatting.

- Consider getting your resume reviewed by a career counselor or professional resume writer.

Essential Experience Highlights for a Strong Welding Pantograph Operator Resume

- Operate welding pantographs to cut, shape, and weld metal components according to blueprints and specifications.

- Select and install appropriate cutting tools and consumables for different materials and thicknesses.

- Set up and calibrate welding pantographs for optimal performance and accuracy.

- Monitor welding processes and make adjustments as needed to maintain quality and productivity.

- Inspect finished products to ensure they meet specifications and industry standards.

- Maintain and repair welding equipment to ensure optimal performance and safety.

- Follow safety protocols and regulations to ensure a safe work environment.

Frequently Asked Questions (FAQ’s) For Welding Pantograph Operator

What is a Welding Pantograph Operator?

A Welding Pantograph Operator is a skilled professional who operates welding pantographs to cut, shape, and weld metal components according to blueprints and specifications.

What skills are required to be a successful Welding Pantograph Operator?

Successful Welding Pantograph Operators typically have a strong understanding of welding techniques, CNC programming, GD&T, and blueprint reading. They are also proficient in the operation and maintenance of welding pantographs.

What industries employ Welding Pantograph Operators?

Welding Pantograph Operators are employed in various industries, including automotive, aerospace, construction, and shipbuilding.

What is the career outlook for Welding Pantograph Operators?

The career outlook for Welding Pantograph Operators is expected to be good in the coming years due to the increasing demand for metal fabrication in various industries.

What is the average salary for a Welding Pantograph Operator?

The average salary for a Welding Pantograph Operator can vary depending on experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Welding, Cutting, and Brazing Workers was $47,700 in May 2021.

What are the benefits of becoming a Welding Pantograph Operator?

Benefits of becoming a Welding Pantograph Operator include job stability, competitive salaries, and opportunities for career advancement. Welding Pantograph Operators are in high demand due to the increasing need for metal fabrication in various industries.