Are you a seasoned Welding Production Supervisor seeking a new career path? Discover our professionally built Welding Production Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

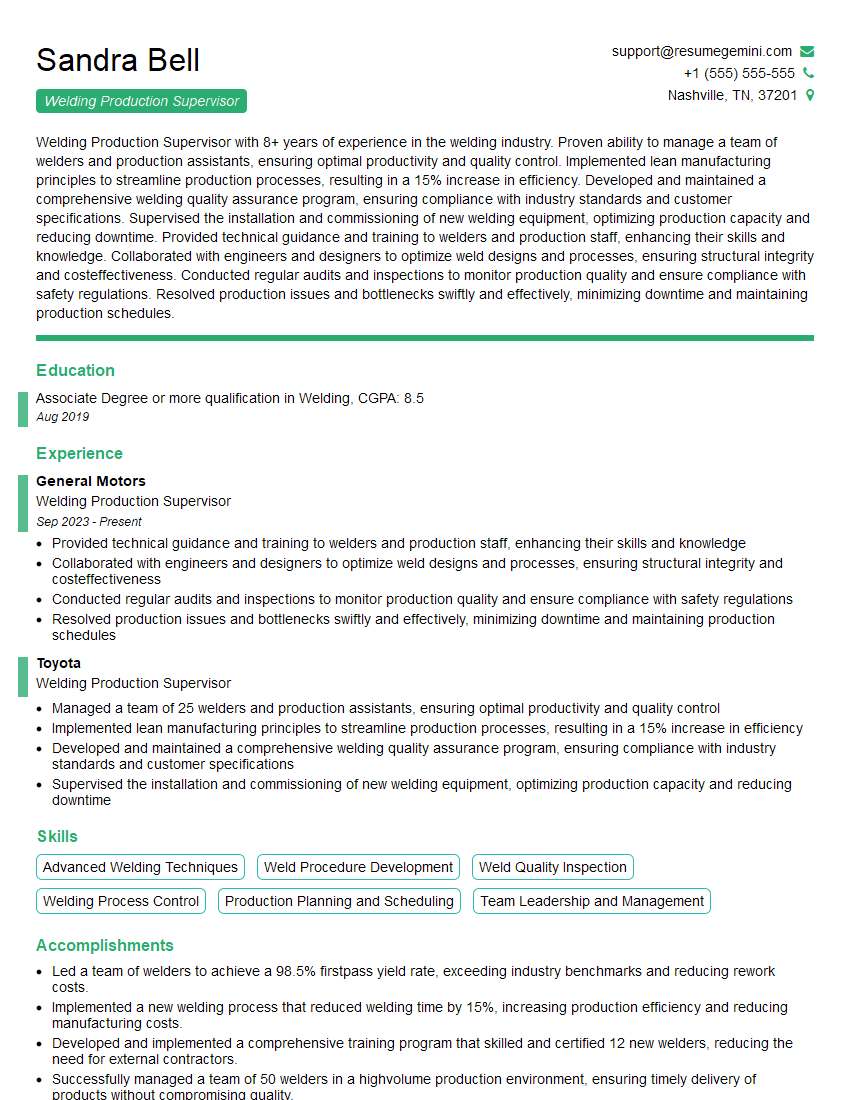

Sandra Bell

Welding Production Supervisor

Summary

Welding Production Supervisor with 8+ years of experience in the welding industry. Proven ability to manage a team of welders and production assistants, ensuring optimal productivity and quality control. Implemented lean manufacturing principles to streamline production processes, resulting in a 15% increase in efficiency. Developed and maintained a comprehensive welding quality assurance program, ensuring compliance with industry standards and customer specifications. Supervised the installation and commissioning of new welding equipment, optimizing production capacity and reducing downtime. Provided technical guidance and training to welders and production staff, enhancing their skills and knowledge. Collaborated with engineers and designers to optimize weld designs and processes, ensuring structural integrity and costeffectiveness. Conducted regular audits and inspections to monitor production quality and ensure compliance with safety regulations. Resolved production issues and bottlenecks swiftly and effectively, minimizing downtime and maintaining production schedules.

Education

Associate Degree or more qualification in Welding

August 2019

Skills

- Advanced Welding Techniques

- Weld Procedure Development

- Weld Quality Inspection

- Welding Process Control

- Production Planning and Scheduling

- Team Leadership and Management

Work Experience

Welding Production Supervisor

- Provided technical guidance and training to welders and production staff, enhancing their skills and knowledge

- Collaborated with engineers and designers to optimize weld designs and processes, ensuring structural integrity and costeffectiveness

- Conducted regular audits and inspections to monitor production quality and ensure compliance with safety regulations

- Resolved production issues and bottlenecks swiftly and effectively, minimizing downtime and maintaining production schedules

Welding Production Supervisor

- Managed a team of 25 welders and production assistants, ensuring optimal productivity and quality control

- Implemented lean manufacturing principles to streamline production processes, resulting in a 15% increase in efficiency

- Developed and maintained a comprehensive welding quality assurance program, ensuring compliance with industry standards and customer specifications

- Supervised the installation and commissioning of new welding equipment, optimizing production capacity and reducing downtime

Accomplishments

- Led a team of welders to achieve a 98.5% firstpass yield rate, exceeding industry benchmarks and reducing rework costs.

- Implemented a new welding process that reduced welding time by 15%, increasing production efficiency and reducing manufacturing costs.

- Developed and implemented a comprehensive training program that skilled and certified 12 new welders, reducing the need for external contractors.

- Successfully managed a team of 50 welders in a highvolume production environment, ensuring timely delivery of products without compromising quality.

- Established and implemented KPIs to monitor welding production performance, identifying areas for improvement and driving efficiency.

Awards

- Recognized with the Supervisor of the Year award for exceptional leadership and contributions to welding production.

- Received the Excellence in Safety award for implementing innovative safety measures that significantly reduced workplace incidents.

- Honored with the Quality Champion award for consistently exceeding quality standards and driving continuous improvement.

- Awarded the Master Welder certification from the American Welding Society, demonstrating expertise in welding techniques and technologies.

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welding Educator (CWE)

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) Inspector

- National Institute for Certification in Engineering Technologies (NICET) Level III Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Welding Production Supervisor

- Highlight your experience in managing a team of welders and production assistants, as well as your ability to implement lean manufacturing principles.

- Showcase your knowledge of welding quality assurance programs and your ability to ensure compliance with industry standards and customer specifications.

- Emphasize your skills in supervising the installation and commissioning of new welding equipment, as well as your ability to provide technical guidance and training to welders and production staff.

- Highlight your ability to collaborate with engineers and designers to optimize weld designs and processes, ensuring structural integrity and cost-effectiveness.

- Demonstrate your skills in conducting regular audits and inspections to monitor production quality and ensure compliance with safety regulations.

Essential Experience Highlights for a Strong Welding Production Supervisor Resume

- Manage a team of welders and production assistants to ensure optimal productivity and quality control

- Implement lean manufacturing principles to streamline production processes, resulting in a 15% increase in efficiency

- Develop and maintain a comprehensive welding quality assurance program, ensuring compliance with industry standards and customer specifications

- Supervise the installation and commissioning of new welding equipment, optimizing production capacity and reducing downtime

- Provide technical guidance and training to welders and production staff, enhancing their skills and knowledge

- Collaborate with engineers and designers to optimize weld designs and processes, ensuring structural integrity and cost-effectiveness

- Conduct regular audits and inspections to monitor production quality and ensure compliance with safety regulations

- Resolve production issues and bottlenecks swiftly and effectively, minimizing downtime and maintaining production schedules

Frequently Asked Questions (FAQ’s) For Welding Production Supervisor

What are the key responsibilities of a Welding Production Supervisor?

The key responsibilities of a Welding Production Supervisor include managing a team of welders and production assistants, implementing lean manufacturing principles, developing and maintaining a comprehensive welding quality assurance program, supervising the installation and commissioning of new welding equipment, providing technical guidance and training to welders and production staff, collaborating with engineers and designers to optimize weld designs and processes, conducting regular audits and inspections to monitor production quality and ensure compliance with safety regulations, and resolving production issues and bottlenecks to improve efficiency and maintain production schedules.

What are the educational requirements for a Welding Production Supervisor?

The educational requirements for a Welding Production Supervisor typically include an associate degree in welding or a related field, as well as training and certification in welding techniques. Some employers may require a bachelor’s degree in welding engineering or a related field.

What are the skills and experience required for a Welding Production Supervisor?

The skills and experience required for a Welding Production Supervisor include strong leadership and management skills, a comprehensive understanding of welding techniques, knowledge of welding quality assurance programs, experience in supervising the installation and commissioning of welding equipment, and the ability to train and develop welders and production staff.

What are the career prospects for a Welding Production Supervisor?

The career prospects for a Welding Production Supervisor are generally favorable, with a steady demand for qualified professionals in a variety of industries. Welding Production Supervisors can advance to management positions, such as Welding Manager or Production Manager, or specialize in a particular area of welding, such as welding engineering or welding inspection.

What is the average salary for a Welding Production Supervisor?

The average salary for a Welding Production Supervisor in the United States is around $67,000 per year, according to the Bureau of Labor Statistics. However, salaries can vary depending on factors such as experience, location, and industry.

What are the common challenges faced by Welding Production Supervisors?

The common challenges faced by Welding Production Supervisors include managing a team of welders and production assistants effectively, implementing lean manufacturing principles, developing and maintaining a comprehensive welding quality assurance program, supervising the installation and commissioning of new welding equipment, providing technical guidance and training to welders and production staff, collaborating with engineers and designers to optimize weld designs and processes, conducting regular audits and inspections to monitor production quality and ensure compliance with safety regulations, and resolving production issues and bottlenecks. To overcome these challenges, Welding Production Supervisors need to have strong leadership and management skills, as well as a deep understanding of welding techniques and quality assurance programs. They must also be able to work effectively with a team of welders and production assistants, and collaborate with engineers and designers to improve efficiency and productivity.

What are the key trends in the welding industry?

The key trends in the welding industry include the increasing use of automation and robotics, the development of new welding techniques, and the growing demand for skilled welders. Welding Production Supervisors need to be aware of these trends and adapt their practices to stay competitive. They need to stay updated on the latest welding techniques and technologies, and be able to train their welders to use these new techniques.

What are the best resources for Welding Production Supervisors?

The best resources for Welding Production Supervisors include the American Welding Society (AWS), the National Institute of Standards and Technology (NIST), and the Occupational Safety and Health Administration (OSHA). These organizations provide a variety of resources, including training programs, certification programs, and safety guidelines.