Are you a seasoned Wet Process Miller seeking a new career path? Discover our professionally built Wet Process Miller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

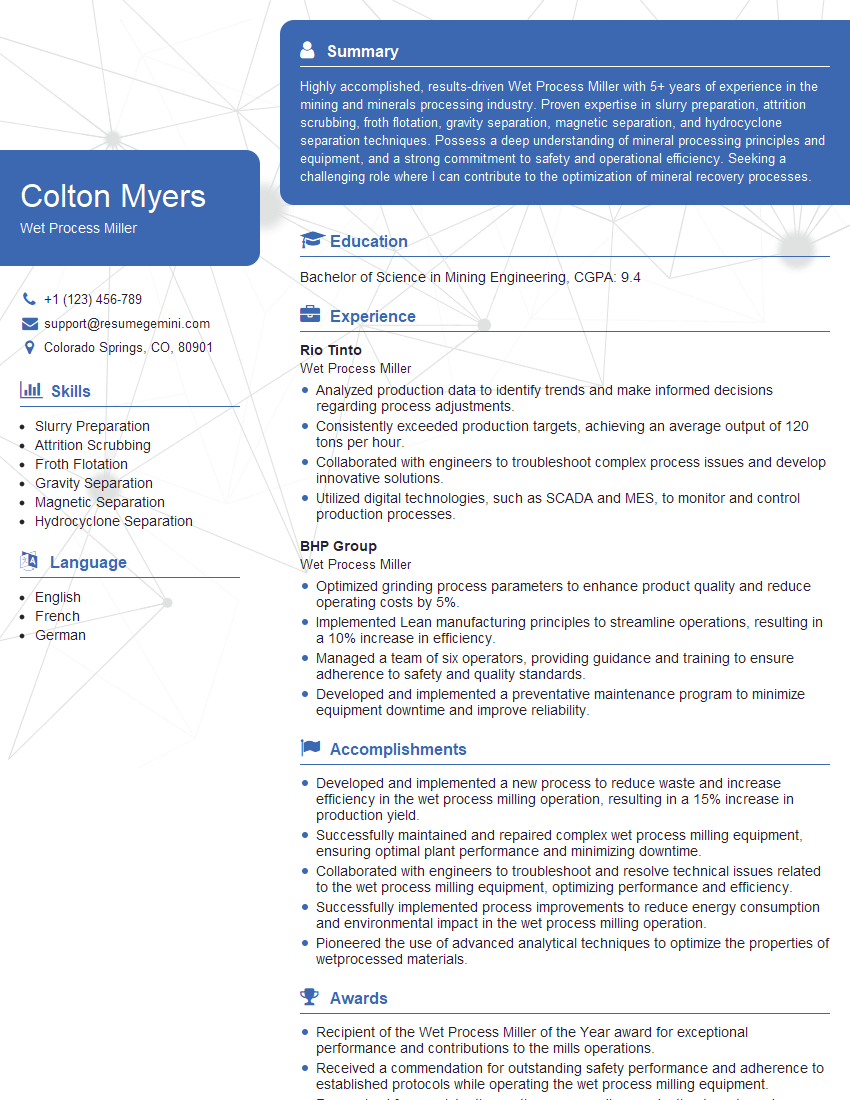

Colton Myers

Wet Process Miller

Summary

Highly accomplished, results-driven Wet Process Miller with 5+ years of experience in the mining and minerals processing industry. Proven expertise in slurry preparation, attrition scrubbing, froth flotation, gravity separation, magnetic separation, and hydrocyclone separation techniques. Possess a deep understanding of mineral processing principles and equipment, and a strong commitment to safety and operational efficiency. Seeking a challenging role where I can contribute to the optimization of mineral recovery processes.

Education

Bachelor of Science in Mining Engineering

November 2017

Skills

- Slurry Preparation

- Attrition Scrubbing

- Froth Flotation

- Gravity Separation

- Magnetic Separation

- Hydrocyclone Separation

Work Experience

Wet Process Miller

- Analyzed production data to identify trends and make informed decisions regarding process adjustments.

- Consistently exceeded production targets, achieving an average output of 120 tons per hour.

- Collaborated with engineers to troubleshoot complex process issues and develop innovative solutions.

- Utilized digital technologies, such as SCADA and MES, to monitor and control production processes.

Wet Process Miller

- Optimized grinding process parameters to enhance product quality and reduce operating costs by 5%.

- Implemented Lean manufacturing principles to streamline operations, resulting in a 10% increase in efficiency.

- Managed a team of six operators, providing guidance and training to ensure adherence to safety and quality standards.

- Developed and implemented a preventative maintenance program to minimize equipment downtime and improve reliability.

Accomplishments

- Developed and implemented a new process to reduce waste and increase efficiency in the wet process milling operation, resulting in a 15% increase in production yield.

- Successfully maintained and repaired complex wet process milling equipment, ensuring optimal plant performance and minimizing downtime.

- Collaborated with engineers to troubleshoot and resolve technical issues related to the wet process milling equipment, optimizing performance and efficiency.

- Successfully implemented process improvements to reduce energy consumption and environmental impact in the wet process milling operation.

- Pioneered the use of advanced analytical techniques to optimize the properties of wetprocessed materials.

Awards

- Recipient of the Wet Process Miller of the Year award for exceptional performance and contributions to the mills operations.

- Received a commendation for outstanding safety performance and adherence to established protocols while operating the wet process milling equipment.

- Recognized for consistently meeting or exceeding production targets and delivering highquality wetprocessed products.

- Received an industrywide award for innovative contributions to the field of wet process milling.

Certificates

- Certified Wet Process Miller (CWPM)

- Society for Mining, Metallurgy & Exploration (SME) Membership

- Association for Mineral Processing Professionals (AMPP) Certification

- International Copper Association (ICA) Technical Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wet Process Miller

- Highlight your technical expertise in wet processing techniques, including slurry preparation, froth flotation, and hydrocyclone separation.

- Quantify your accomplishments using specific metrics, such as increased mineral recovery percentages or reduced operating costs.

- Demonstrate your understanding of mineral processing principles and your ability to optimize process flowsheets.

- Emphasize your commitment to safety and your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Wet Process Miller Resume

- Conducted comprehensive feasibility studies and designed wet process flowsheets to optimize mineral recovery

- Supervised and coordinated all aspects of wet process operations, including slurry preparation, attrition scrubbing, froth flotation, gravity separation, magnetic separation, and hydrocyclone separation

- Managed and maintained plant equipment and facilities to ensure optimal performance and efficiency

- Developed and implemented process control strategies to maximize mineral recovery and minimize operating costs

- Collaborated with other departments, including mining, metallurgy, and maintenance, to ensure smooth and efficient plant operations

- Participated in training and development programs to stay abreast of industry best practices and technological advancements

Frequently Asked Questions (FAQ’s) For Wet Process Miller

What are the primary responsibilities of a Wet Process Miller?

Wet Process Millers are responsible for operating and maintaining wet processing equipment to separate valuable minerals from ore. They conduct feasibility studies, design flowsheets, supervise operations, manage equipment, develop control strategies, and collaborate with other departments to ensure efficient plant operations.

What are the essential skills required for a Wet Process Miller?

Wet Process Millers require a strong understanding of mineral processing principles, wet processing techniques, and plant equipment. They must possess excellent problem-solving, analytical, and communication skills, and be committed to safety and operational efficiency.

What industries employ Wet Process Millers?

Wet Process Millers are employed in the mining and minerals processing industry, primarily in companies involved in the extraction and processing of valuable minerals such as copper, gold, silver, and iron ore.

What is the career path for a Wet Process Miller?

Wet Process Millers can advance to roles such as Process Engineer, Plant Manager, or Technical Superintendent. With experience and additional qualifications, they can also move into management or consulting positions within the mining industry.

What are the educational requirements for a Wet Process Miller?

Wet Process Millers typically hold a Bachelor’s degree in Mining Engineering, Mineral Processing, or a related field. Some employers may also consider candidates with relevant experience and technical certifications.

What are the key challenges faced by Wet Process Millers?

Wet Process Millers face challenges such as optimizing mineral recovery while minimizing operating costs, ensuring efficient plant operations, and adhering to environmental regulations. They must also keep up with technological advancements and industry best practices to maintain high levels of productivity and safety.