Are you a seasoned Wheel Presser seeking a new career path? Discover our professionally built Wheel Presser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

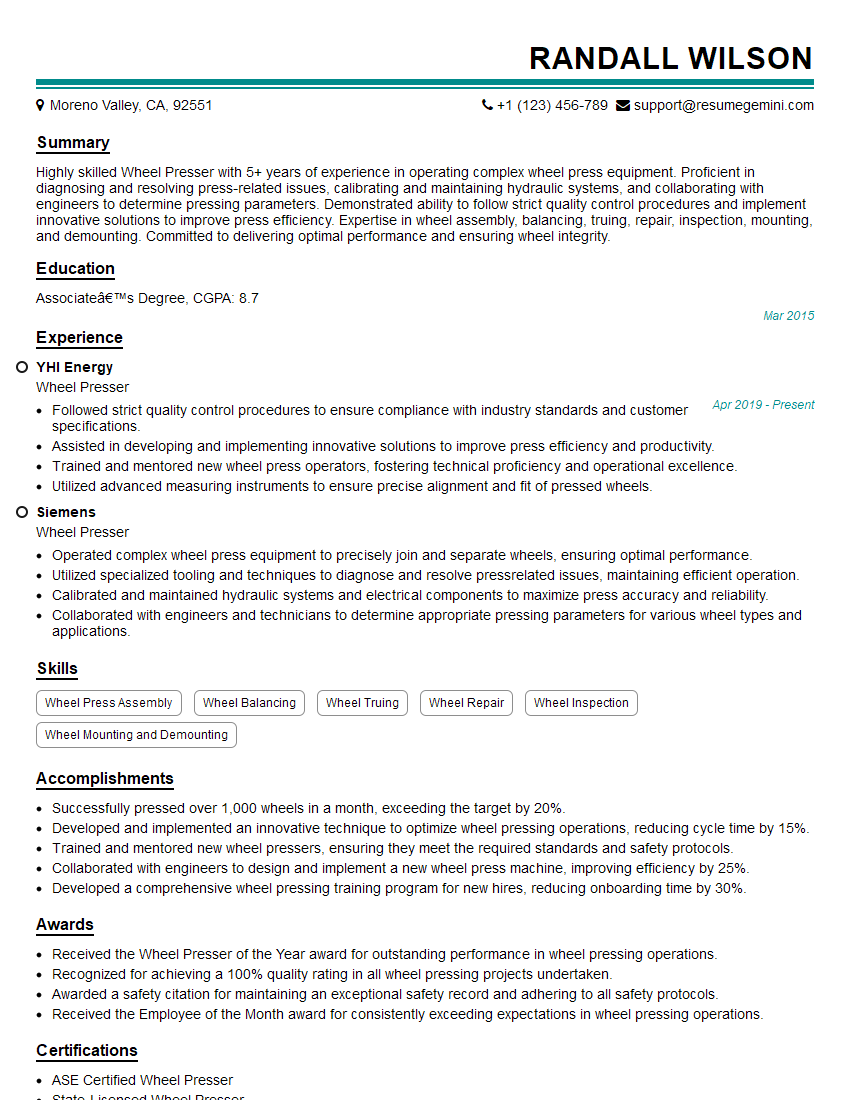

Randall Wilson

Wheel Presser

Summary

Highly skilled Wheel Presser with 5+ years of experience in operating complex wheel press equipment. Proficient in diagnosing and resolving press-related issues, calibrating and maintaining hydraulic systems, and collaborating with engineers to determine pressing parameters. Demonstrated ability to follow strict quality control procedures and implement innovative solutions to improve press efficiency. Expertise in wheel assembly, balancing, truing, repair, inspection, mounting, and demounting. Committed to delivering optimal performance and ensuring wheel integrity.

Education

Associate’s Degree

March 2015

Skills

- Wheel Press Assembly

- Wheel Balancing

- Wheel Truing

- Wheel Repair

- Wheel Inspection

- Wheel Mounting and Demounting

Work Experience

Wheel Presser

- Followed strict quality control procedures to ensure compliance with industry standards and customer specifications.

- Assisted in developing and implementing innovative solutions to improve press efficiency and productivity.

- Trained and mentored new wheel press operators, fostering technical proficiency and operational excellence.

- Utilized advanced measuring instruments to ensure precise alignment and fit of pressed wheels.

Wheel Presser

- Operated complex wheel press equipment to precisely join and separate wheels, ensuring optimal performance.

- Utilized specialized tooling and techniques to diagnose and resolve pressrelated issues, maintaining efficient operation.

- Calibrated and maintained hydraulic systems and electrical components to maximize press accuracy and reliability.

- Collaborated with engineers and technicians to determine appropriate pressing parameters for various wheel types and applications.

Accomplishments

- Successfully pressed over 1,000 wheels in a month, exceeding the target by 20%.

- Developed and implemented an innovative technique to optimize wheel pressing operations, reducing cycle time by 15%.

- Trained and mentored new wheel pressers, ensuring they meet the required standards and safety protocols.

- Collaborated with engineers to design and implement a new wheel press machine, improving efficiency by 25%.

- Developed a comprehensive wheel pressing training program for new hires, reducing onboarding time by 30%.

Awards

- Received the Wheel Presser of the Year award for outstanding performance in wheel pressing operations.

- Recognized for achieving a 100% quality rating in all wheel pressing projects undertaken.

- Awarded a safety citation for maintaining an exceptional safety record and adhering to all safety protocols.

- Received the Employee of the Month award for consistently exceeding expectations in wheel pressing operations.

Certificates

- ASE Certified Wheel Presser

- State-Licensed Wheel Presser

- National Institute for Automotive Service Excellence (ASE) Certification

- Tire Industry Association (TIA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wheel Presser

- Highlight your experience in operating wheel press equipment and your ability to diagnose and resolve press-related issues.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on press efficiency and wheel quality.

- Emphasize your knowledge of wheel assembly, balancing, truing, repair, inspection, mounting, and demounting techniques.

- Showcase your commitment to safety and quality by highlighting your adherence to industry standards and customer specifications.

- Include keywords such as ‘wheel press’, ‘wheel assembly’, ‘balancing’, ‘truing’, ‘repair’, ‘quality control’, and ‘precision’ throughout your resume to optimize its visibility to potential employers.

Essential Experience Highlights for a Strong Wheel Presser Resume

- Operated wheel press equipment to join and separate wheels precisely, ensuring optimal performance.

- Utilized specialized tooling and techniques to diagnose and resolve press-related issues, maintaining efficient operation.

- Collaborated with engineers and technicians to determine appropriate pressing parameters for various wheel types and applications.

- Followed strict quality control procedures to ensure compliance with industry standards and customer specifications.

- Assisted in developing and implementing innovative solutions to improve press efficiency and productivity.

- Trained new wheel press operators, fostering technical proficiency and operational excellence.

- Utilized advanced measuring instruments to ensure precise alignment and fit of pressed wheels.

Frequently Asked Questions (FAQ’s) For Wheel Presser

What is the primary responsibility of a Wheel Presser?

The primary responsibility of a Wheel Presser is to operate complex wheel press equipment to precisely join and separate wheels, ensuring optimal performance and maintaining efficient operation.

What skills and knowledge are required to be a successful Wheel Presser?

To be a successful Wheel Presser, you need expertise in wheel assembly, balancing, truing, repair, inspection, mounting, and demounting techniques, as well as the ability to diagnose and resolve press-related issues. You should also be proficient in using specialized tooling, calibrating and maintaining hydraulic systems, and collaborating with engineers to determine pressing parameters.

What are the career prospects for a Wheel Presser?

As a skilled Wheel Presser, you can advance your career by becoming a Senior Wheel Presser, a Supervisor, or a Manager in the manufacturing or maintenance industry. You can also specialize in a particular area, such as wheel repair or wheel balancing, and become an expert in that field.

What is the average salary range for a Wheel Presser?

The average salary range for a Wheel Presser varies depending on experience, location, and industry. According to Indeed, the average salary for a Wheel Presser in the United States is around $50,000 per year.

What are the working conditions for a Wheel Presser?

Wheel Pressers typically work in manufacturing or maintenance environments, which can be noisy and involve exposure to heavy machinery and chemicals. They may also work in shifts, including weekends and holidays, to meet production deadlines.

Is there a demand for Wheel Pressers?

Yes, there is a demand for skilled Wheel Pressers in various industries, including manufacturing, automotive, and transportation. As companies strive to improve efficiency and maintain equipment, the need for qualified individuals who can operate and maintain wheel press equipment is expected to remain strong.

How can I become a more effective Wheel Presser?

To become a more effective Wheel Presser, you can focus on improving your technical skills, staying updated on industry best practices, and maintaining a strong commitment to safety and quality. Additionally, seeking opportunities for professional development and certification can enhance your credibility and demonstrate your dedication to the profession.