Are you a seasoned Winding Machine Operator seeking a new career path? Discover our professionally built Winding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

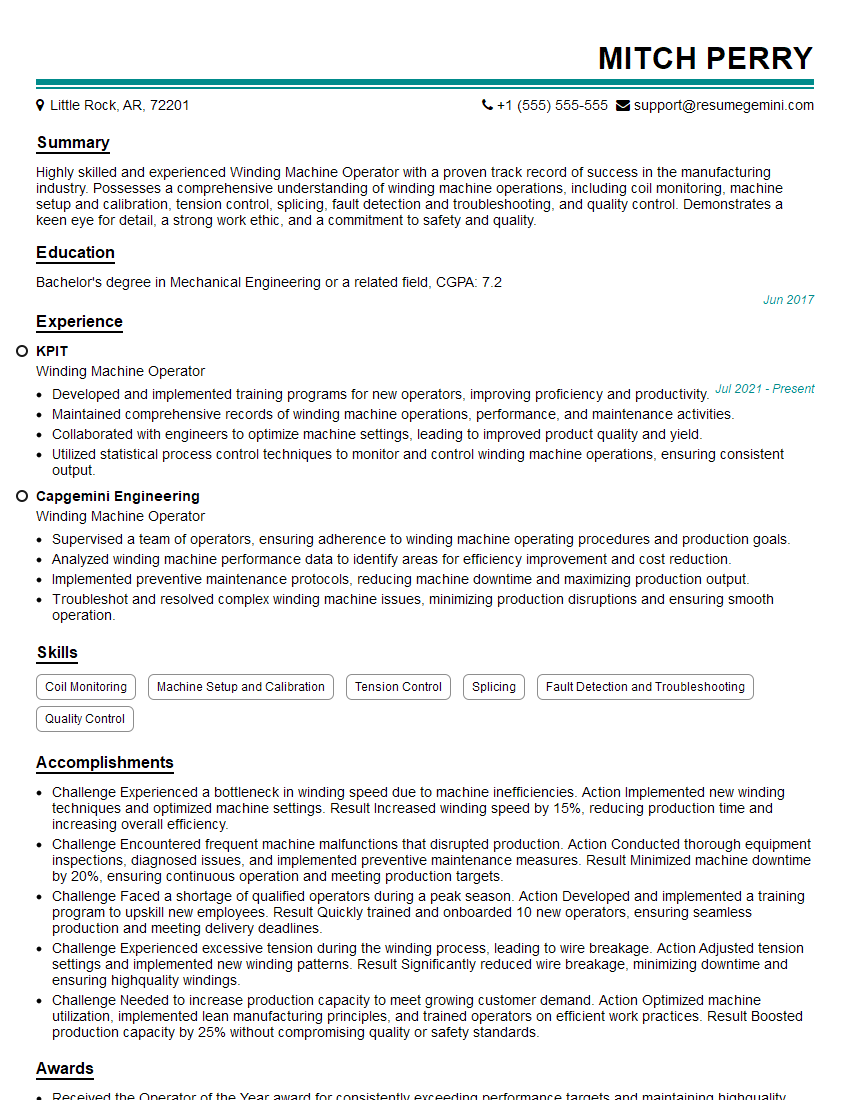

Mitch Perry

Winding Machine Operator

Summary

Highly skilled and experienced Winding Machine Operator with a proven track record of success in the manufacturing industry. Possesses a comprehensive understanding of winding machine operations, including coil monitoring, machine setup and calibration, tension control, splicing, fault detection and troubleshooting, and quality control. Demonstrates a keen eye for detail, a strong work ethic, and a commitment to safety and quality.

Education

Bachelor’s degree in Mechanical Engineering or a related field

June 2017

Skills

- Coil Monitoring

- Machine Setup and Calibration

- Tension Control

- Splicing

- Fault Detection and Troubleshooting

- Quality Control

Work Experience

Winding Machine Operator

- Developed and implemented training programs for new operators, improving proficiency and productivity.

- Maintained comprehensive records of winding machine operations, performance, and maintenance activities.

- Collaborated with engineers to optimize machine settings, leading to improved product quality and yield.

- Utilized statistical process control techniques to monitor and control winding machine operations, ensuring consistent output.

Winding Machine Operator

- Supervised a team of operators, ensuring adherence to winding machine operating procedures and production goals.

- Analyzed winding machine performance data to identify areas for efficiency improvement and cost reduction.

- Implemented preventive maintenance protocols, reducing machine downtime and maximizing production output.

- Troubleshot and resolved complex winding machine issues, minimizing production disruptions and ensuring smooth operation.

Accomplishments

- Challenge Experienced a bottleneck in winding speed due to machine inefficiencies. Action Implemented new winding techniques and optimized machine settings. Result Increased winding speed by 15%, reducing production time and increasing overall efficiency.

- Challenge Encountered frequent machine malfunctions that disrupted production. Action Conducted thorough equipment inspections, diagnosed issues, and implemented preventive maintenance measures. Result Minimized machine downtime by 20%, ensuring continuous operation and meeting production targets.

- Challenge Faced a shortage of qualified operators during a peak season. Action Developed and implemented a training program to upskill new employees. Result Quickly trained and onboarded 10 new operators, ensuring seamless production and meeting delivery deadlines.

- Challenge Experienced excessive tension during the winding process, leading to wire breakage. Action Adjusted tension settings and implemented new winding patterns. Result Significantly reduced wire breakage, minimizing downtime and ensuring highquality windings.

- Challenge Needed to increase production capacity to meet growing customer demand. Action Optimized machine utilization, implemented lean manufacturing principles, and trained operators on efficient work practices. Result Boosted production capacity by 25% without compromising quality or safety standards.

Awards

- Received the Operator of the Year award for consistently exceeding performance targets and maintaining highquality output.

- Recognized for exceptional contributions to the winding team, resulting in a significant reduction in production defects.

- Received the Safety Champion award for maintaining an impeccable safety record and promoting a positive safety culture within the winding department.

- Recognized for developing innovative winding methods that improved product quality and reduced material waste.

Certificates

- Certified Winding Machine Operator (CWMO)

- OSHA Safety Certification

- ISO 9001 Certification

- CMRP (Certified Maintenance & Reliability Professional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Winding Machine Operator

- Highlight your experience with specific winding machines, such as CNC winding machines or manual winding machines.

- Showcase your expertise in winding techniques, such as coil winding, toroidal winding, and multilayer winding.

- Emphasize your ability to work in a fast-paced environment and meet deadlines.

- Include any certifications or training related to winding machines or quality control.

Essential Experience Highlights for a Strong Winding Machine Operator Resume

- Monitor coils during winding and make adjustments as needed to ensure proper winding tension

- Set up and calibrate winding machines according to specifications

- Control tension during winding to prevent breakage and ensure proper coil formation

- Splice wires together to create continuous coils

- Detect and troubleshoot faults in winding machines to minimize downtime

- Perform quality control checks on finished coils to ensure they meet specifications

- Maintain a clean and organized work area, following all safety protocols

Frequently Asked Questions (FAQ’s) For Winding Machine Operator

What are the key skills required to become a Winding Machine Operator?

The key skills required to become a Winding Machine Operator include coil monitoring, machine setup and calibration, tension control, splicing, fault detection and troubleshooting, quality control, and a strong understanding of electrical and mechanical principles.

What are the career opportunities for Winding Machine Operators?

Winding Machine Operators can advance to roles such as Winding Machine Supervisors, Quality Control Inspectors, or Production Managers. With additional training and experience, they can also move into roles in engineering or management.

What is the work environment like for Winding Machine Operators?

Winding Machine Operators typically work in manufacturing facilities, operating winding machines in a production line setting. The work environment can be noisy and fast-paced, but it is also highly rewarding.

What are the safety precautions that Winding Machine Operators should take?

Winding Machine Operators should always wear appropriate safety gear, including safety glasses, gloves, and earplugs. They should also be aware of the potential hazards associated with winding machines, such as electrical shock, cuts, and burns.

What are the certifications that Winding Machine Operators can obtain?

Winding Machine Operators can obtain certifications from organizations such as the National Institute for Metalworking Skills (NIMS) or the American Welding Society (AWS). These certifications can demonstrate their skills and knowledge to potential employers.

What is the average salary for Winding Machine Operators?

The average salary for Winding Machine Operators can vary depending on their experience, skills, and location. According to Indeed, the average salary for Winding Machine Operators in the United States is around $22.50 per hour.

What is the job outlook for Winding Machine Operators?

The job outlook for Winding Machine Operators is expected to be positive in the coming years. The increasing demand for electrical and electronic products is expected to lead to increased demand for Winding Machine Operators.