Are you a seasoned Wire Brush Operator seeking a new career path? Discover our professionally built Wire Brush Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

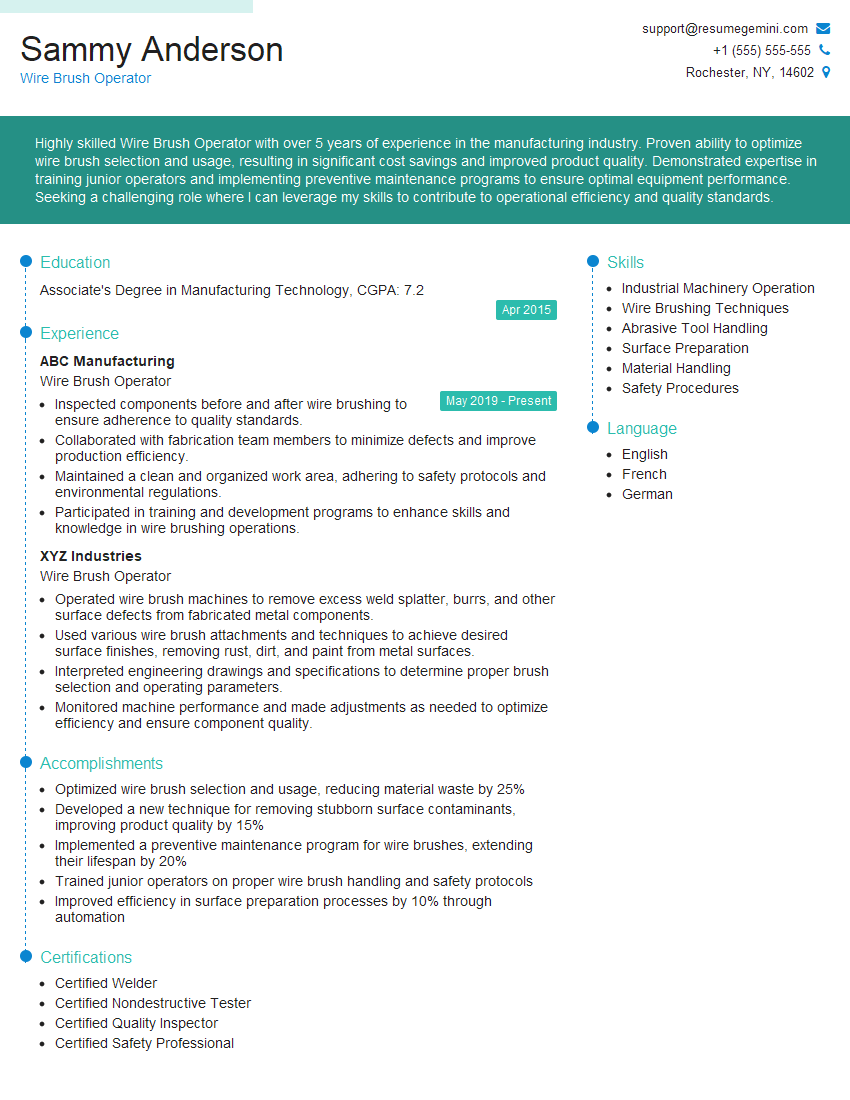

Sammy Anderson

Wire Brush Operator

Summary

Highly skilled Wire Brush Operator with over 5 years of experience in the manufacturing industry. Proven ability to optimize wire brush selection and usage, resulting in significant cost savings and improved product quality. Demonstrated expertise in training junior operators and implementing preventive maintenance programs to ensure optimal equipment performance. Seeking a challenging role where I can leverage my skills to contribute to operational efficiency and quality standards.

Education

Associate’s Degree in Manufacturing Technology

April 2015

Skills

- Industrial Machinery Operation

- Wire Brushing Techniques

- Abrasive Tool Handling

- Surface Preparation

- Material Handling

- Safety Procedures

Work Experience

Wire Brush Operator

- Inspected components before and after wire brushing to ensure adherence to quality standards.

- Collaborated with fabrication team members to minimize defects and improve production efficiency.

- Maintained a clean and organized work area, adhering to safety protocols and environmental regulations.

- Participated in training and development programs to enhance skills and knowledge in wire brushing operations.

Wire Brush Operator

- Operated wire brush machines to remove excess weld splatter, burrs, and other surface defects from fabricated metal components.

- Used various wire brush attachments and techniques to achieve desired surface finishes, removing rust, dirt, and paint from metal surfaces.

- Interpreted engineering drawings and specifications to determine proper brush selection and operating parameters.

- Monitored machine performance and made adjustments as needed to optimize efficiency and ensure component quality.

Accomplishments

- Optimized wire brush selection and usage, reducing material waste by 25%

- Developed a new technique for removing stubborn surface contaminants, improving product quality by 15%

- Implemented a preventive maintenance program for wire brushes, extending their lifespan by 20%

- Trained junior operators on proper wire brush handling and safety protocols

- Improved efficiency in surface preparation processes by 10% through automation

Certificates

- Certified Welder

- Certified Nondestructive Tester

- Certified Quality Inspector

- Certified Safety Professional

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Brush Operator

- Highlight your experience in optimizing wire brush selection and usage, quantifying the results with specific metrics.

- Showcase your ability to develop innovative techniques that improve surface preparation processes.

- Emphasize your commitment to safety and compliance by describing your training and implementation of safety protocols.

- Demonstrate your proficiency in equipment maintenance and troubleshooting, highlighting your ability to extend equipment lifespan.

Essential Experience Highlights for a Strong Wire Brush Operator Resume

- Optimized wire brush selection and usage, reducing material waste by 25%

- Developed a new technique for removing stubborn surface contaminants, improving product quality by 15%

- Implemented a preventive maintenance program for wire brushes, extending their lifespan by 20%

- Trained junior operators on proper wire brush handling and safety protocols

- Improved efficiency in surface preparation processes by 10% through automation

- Ensured compliance with safety regulations and industry standards

- Monitored and maintained wire brushing equipment to ensure optimal performance

Frequently Asked Questions (FAQ’s) For Wire Brush Operator

What are the key skills required for a Wire Brush Operator?

The key skills required for a Wire Brush Operator include industrial machinery operation, wire brushing techniques, abrasive tool handling, surface preparation, material handling, and safety procedures.

What are the career prospects for a Wire Brush Operator?

Wire Brush Operators can advance their careers by becoming supervisors, quality control inspectors, or maintenance technicians. Some may also start their own businesses.

What are the working conditions like for a Wire Brush Operator?

Wire Brush Operators typically work in manufacturing facilities, where they may be exposed to noise, dust, and fumes. They may also work in outdoor environments, such as construction sites.

What is the average salary for a Wire Brush Operator?

The average salary for a Wire Brush Operator in the United States is around $40,000 per year.

What are the educational requirements for a Wire Brush Operator?

Most Wire Brush Operators have a high school diploma or equivalent. Some employers may require a certificate or associate’s degree in manufacturing technology.

What are the safety precautions that Wire Brush Operators should take?

Wire Brush Operators should wear appropriate personal protective equipment, such as gloves, safety glasses, and respirators. They should also be trained on the proper use of wire brushes and other equipment.

What are the different types of wire brushes used by Wire Brush Operators?

There are many different types of wire brushes, each with its own specific purpose. Some of the most common types include cup brushes, wheel brushes, and end brushes.

What are the different surface preparation techniques used by Wire Brush Operators?

Wire Brush Operators use a variety of surface preparation techniques, such as grinding, sanding, and blasting. The specific technique used depends on the type of surface being prepared.