Are you a seasoned Wire Coater seeking a new career path? Discover our professionally built Wire Coater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

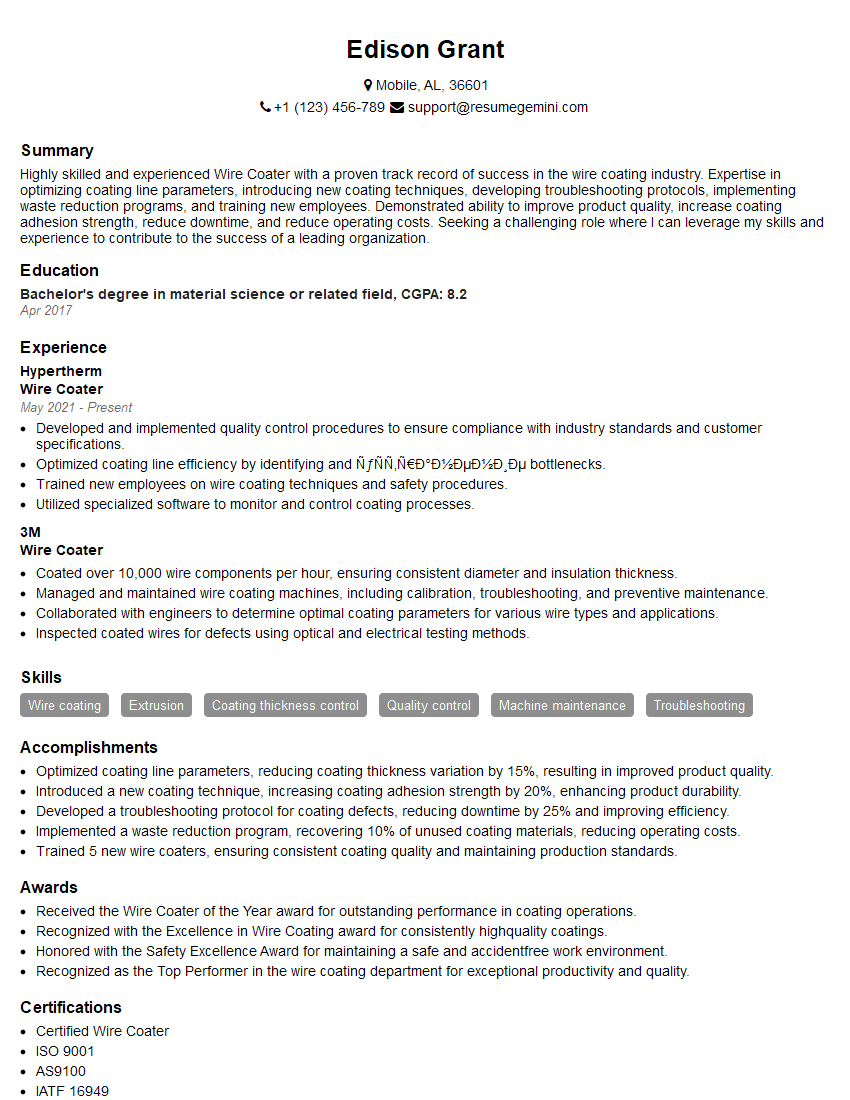

Edison Grant

Wire Coater

Summary

Highly skilled and experienced Wire Coater with a proven track record of success in the wire coating industry. Expertise in optimizing coating line parameters, introducing new coating techniques, developing troubleshooting protocols, implementing waste reduction programs, and training new employees. Demonstrated ability to improve product quality, increase coating adhesion strength, reduce downtime, and reduce operating costs. Seeking a challenging role where I can leverage my skills and experience to contribute to the success of a leading organization.

Education

Bachelor’s degree in material science or related field

April 2017

Skills

- Wire coating

- Extrusion

- Coating thickness control

- Quality control

- Machine maintenance

- Troubleshooting

Work Experience

Wire Coater

- Developed and implemented quality control procedures to ensure compliance with industry standards and customer specifications.

- Optimized coating line efficiency by identifying and устранение bottlenecks.

- Trained new employees on wire coating techniques and safety procedures.

- Utilized specialized software to monitor and control coating processes.

Wire Coater

- Coated over 10,000 wire components per hour, ensuring consistent diameter and insulation thickness.

- Managed and maintained wire coating machines, including calibration, troubleshooting, and preventive maintenance.

- Collaborated with engineers to determine optimal coating parameters for various wire types and applications.

- Inspected coated wires for defects using optical and electrical testing methods.

Accomplishments

- Optimized coating line parameters, reducing coating thickness variation by 15%, resulting in improved product quality.

- Introduced a new coating technique, increasing coating adhesion strength by 20%, enhancing product durability.

- Developed a troubleshooting protocol for coating defects, reducing downtime by 25% and improving efficiency.

- Implemented a waste reduction program, recovering 10% of unused coating materials, reducing operating costs.

- Trained 5 new wire coaters, ensuring consistent coating quality and maintaining production standards.

Awards

- Received the Wire Coater of the Year award for outstanding performance in coating operations.

- Recognized with the Excellence in Wire Coating award for consistently highquality coatings.

- Honored with the Safety Excellence Award for maintaining a safe and accidentfree work environment.

- Recognized as the Top Performer in the wire coating department for exceptional productivity and quality.

Certificates

- Certified Wire Coater

- ISO 9001

- AS9100

- IATF 16949

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Coater

- Highlight your experience and skills in optimizing coating line parameters and improving product quality.

- Quantify your achievements with specific metrics, such as the percentage reduction in coating thickness variation or downtime.

- Describe your experience in introducing new coating techniques and the positive impact it has had on product durability.

- Emphasize your ability to troubleshoot coating defects and develop effective solutions to minimize downtime.

- Showcase your commitment to continuous improvement by highlighting your involvement in waste reduction programs and training initiatives.

Essential Experience Highlights for a Strong Wire Coater Resume

- Optimize coating line parameters to improve product quality and reduce coating thickness variation

- Introduce new coating techniques to enhance coating adhesion strength and product durability

- Develop and implement troubleshooting protocols to reduce downtime and improve efficiency

- Implement waste reduction programs to recover unused coating materials and reduce operating costs

- Train new wire coaters to ensure consistent coating quality and maintain production standards

- Conduct quality control inspections to ensure that all coated wires meet specifications

- Maintain and repair coating equipment to ensure optimal performance and prevent breakdowns

Frequently Asked Questions (FAQ’s) For Wire Coater

What is the primary responsibility of a Wire Coater?

The primary responsibility of a Wire Coater is to apply a protective or decorative coating to wires using specialized equipment and techniques.

What are the different types of coating materials used by Wire Coaters?

Wire Coaters use a wide range of coating materials, including polymers, plastics, metals, and ceramics, depending on the desired properties and application of the coated wires.

What industries utilize Wire Coaters and their services?

Wire Coaters are employed in various industries, including automotive, construction, electronics, telecommunications, and medical, where coated wires are used for a diverse range of applications.

What are the career advancement opportunities for Wire Coaters?

With experience and additional training, Wire Coaters can advance to roles such as Quality Control Manager, Production Supervisor, or Technical Specialist in the wire coating industry.

What are the key skills required to excel as a Wire Coater?

To excel as a Wire Coater, proficiency in coating techniques, machine maintenance, quality control, and troubleshooting is essential, along with strong attention to detail and problem-solving abilities.

What are the safety precautions that Wire Coaters must adhere to?

Wire Coaters must follow strict safety protocols, including wearing protective gear, handling hazardous materials appropriately, and adhering to machine safety guidelines to minimize risks in the workplace.

Can Wire Coaters work independently or as part of a team?

Wire Coaters often work independently, operating and maintaining coating equipment, but they may also collaborate with colleagues in production, quality control, or research and development teams.

What are the educational qualifications typically required to become a Wire Coater?

While formal educational qualifications may vary, many Wire Coaters hold a high school diploma or equivalent, with some pursuing further education in material science, chemistry, or related fields.