Are you a seasoned Wire Coating Machine Operator seeking a new career path? Discover our professionally built Wire Coating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

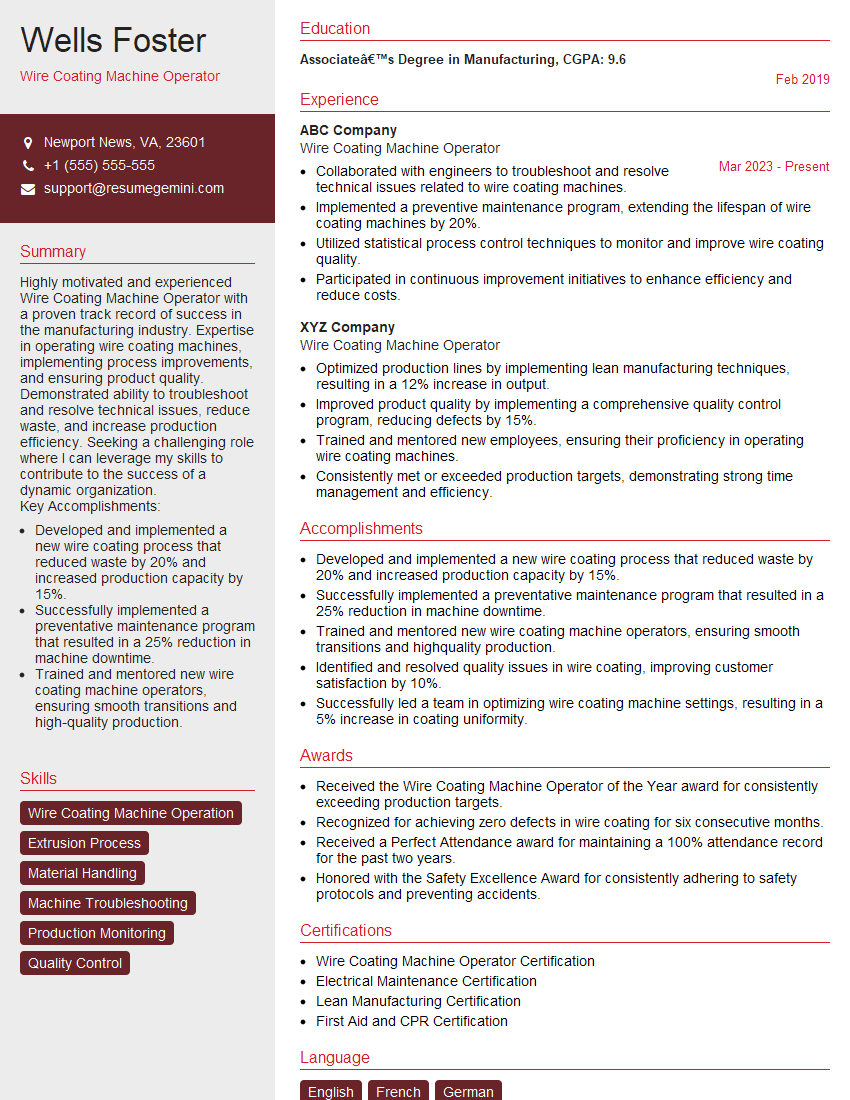

Wells Foster

Wire Coating Machine Operator

Summary

Highly motivated and experienced Wire Coating Machine Operator with a proven track record of success in the manufacturing industry. Expertise in operating wire coating machines, implementing process improvements, and ensuring product quality. Demonstrated ability to troubleshoot and resolve technical issues, reduce waste, and increase production efficiency. Seeking a challenging role where I can leverage my skills to contribute to the success of a dynamic organization.

Key Accomplishments:

- Developed and implemented a new wire coating process that reduced waste by 20% and increased production capacity by 15%.

- Successfully implemented a preventative maintenance program that resulted in a 25% reduction in machine downtime.

- Trained and mentored new wire coating machine operators, ensuring smooth transitions and high-quality production.

Education

Associate’s Degree in Manufacturing

February 2019

Skills

- Wire Coating Machine Operation

- Extrusion Process

- Material Handling

- Machine Troubleshooting

- Production Monitoring

- Quality Control

Work Experience

Wire Coating Machine Operator

- Collaborated with engineers to troubleshoot and resolve technical issues related to wire coating machines.

- Implemented a preventive maintenance program, extending the lifespan of wire coating machines by 20%.

- Utilized statistical process control techniques to monitor and improve wire coating quality.

- Participated in continuous improvement initiatives to enhance efficiency and reduce costs.

Wire Coating Machine Operator

- Optimized production lines by implementing lean manufacturing techniques, resulting in a 12% increase in output.

- Improved product quality by implementing a comprehensive quality control program, reducing defects by 15%.

- Trained and mentored new employees, ensuring their proficiency in operating wire coating machines.

- Consistently met or exceeded production targets, demonstrating strong time management and efficiency.

Accomplishments

- Developed and implemented a new wire coating process that reduced waste by 20% and increased production capacity by 15%.

- Successfully implemented a preventative maintenance program that resulted in a 25% reduction in machine downtime.

- Trained and mentored new wire coating machine operators, ensuring smooth transitions and highquality production.

- Identified and resolved quality issues in wire coating, improving customer satisfaction by 10%.

- Successfully led a team in optimizing wire coating machine settings, resulting in a 5% increase in coating uniformity.

Awards

- Received the Wire Coating Machine Operator of the Year award for consistently exceeding production targets.

- Recognized for achieving zero defects in wire coating for six consecutive months.

- Received a Perfect Attendance award for maintaining a 100% attendance record for the past two years.

- Honored with the Safety Excellence Award for consistently adhering to safety protocols and preventing accidents.

Certificates

- Wire Coating Machine Operator Certification

- Electrical Maintenance Certification

- Lean Manufacturing Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Coating Machine Operator

- Highlight your experience and skills in operating wire coating machines, including any specific types or models you have worked on.

- Quantify your accomplishments with specific metrics, such as the percentage of waste reduction or increase in production capacity you achieved.

- Showcase your problem-solving and troubleshooting skills by describing how you identified and resolved technical issues.

- Emphasize your attention to detail and commitment to quality by providing examples of how you ensured product quality and maintained a clean and organized work environment.

Essential Experience Highlights for a Strong Wire Coating Machine Operator Resume

- Operate wire coating machines to apply a protective or decorative coating to wire.

- Control machine settings to ensure proper coating thickness, uniformity, and quality.

- Monitor production process and make adjustments as needed to optimize performance.

- Inspect coated wire for defects and ensure it meets specifications.

- Perform routine maintenance and troubleshooting on wire coating machines.

- Maintain a clean and organized work area and follow safety procedures.

Frequently Asked Questions (FAQ’s) For Wire Coating Machine Operator

What are the key skills and qualifications required to be a successful Wire Coating Machine Operator?

The key skills and qualifications required to be a successful Wire Coating Machine Operator include: – Strong understanding of wire coating processes and equipment – Ability to operate and maintain wire coating machines – Knowledge of quality control procedures – Excellent attention to detail – Good problem-solving and troubleshooting skills – Physical ability to stand for long periods and lift heavy objects

What are the career opportunities for Wire Coating Machine Operators?

Wire Coating Machine Operators can advance to supervisory or management positions within the manufacturing industry. They may also specialize in a particular type of wire coating or work with specific materials.

What is the work environment of a Wire Coating Machine Operator like?

The work environment of a Wire Coating Machine Operator is typically a manufacturing plant. The work can be physically demanding and may involve exposure to hazardous chemicals.

How can I prepare for a career as a Wire Coating Machine Operator?

There are a few things you can do to prepare for a career as a Wire Coating Machine Operator: – Earn a high school diploma or equivalent – Take courses in manufacturing, engineering, or a related field – Gain experience operating machinery and working with hazardous materials – Network with people in the manufacturing industry – Apply for entry-level positions as a Wire Coating Machine Operator or a related role

What are the safety precautions that Wire Coating Machine Operators should follow?

Wire Coating Machine Operators should follow all safety precautions outlined by their employer and the manufacturer of the equipment they are operating. These precautions may include: – Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator – Operating machines only when they are properly guarded – Following proper lockout/tagout procedures – Being aware of the potential hazards associated with the chemicals they are using – Reporting any unsafe conditions or practices to their supervisor immediately

What are the benefits of being a Wire Coating Machine Operator?

The benefits of being a Wire Coating Machine Operator can include: – Competitive salary and benefits – Opportunities for advancement – Job security – A sense of accomplishment from producing a quality product

What are the challenges of being a Wire Coating Machine Operator?

The challenges of being a Wire Coating Machine Operator can include: – Working in a physically demanding environment – Exposure to hazardous chemicals – Repetitive work – Long hours

Is Wire Coating Machine Operator a good career choice?

Wire Coating Machine Operator can be a good career choice for people who are interested in working in the manufacturing industry. It is a stable and well-paying job with opportunities for advancement.