Are you a seasoned Wire Coiler Machine Operator seeking a new career path? Discover our professionally built Wire Coiler Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

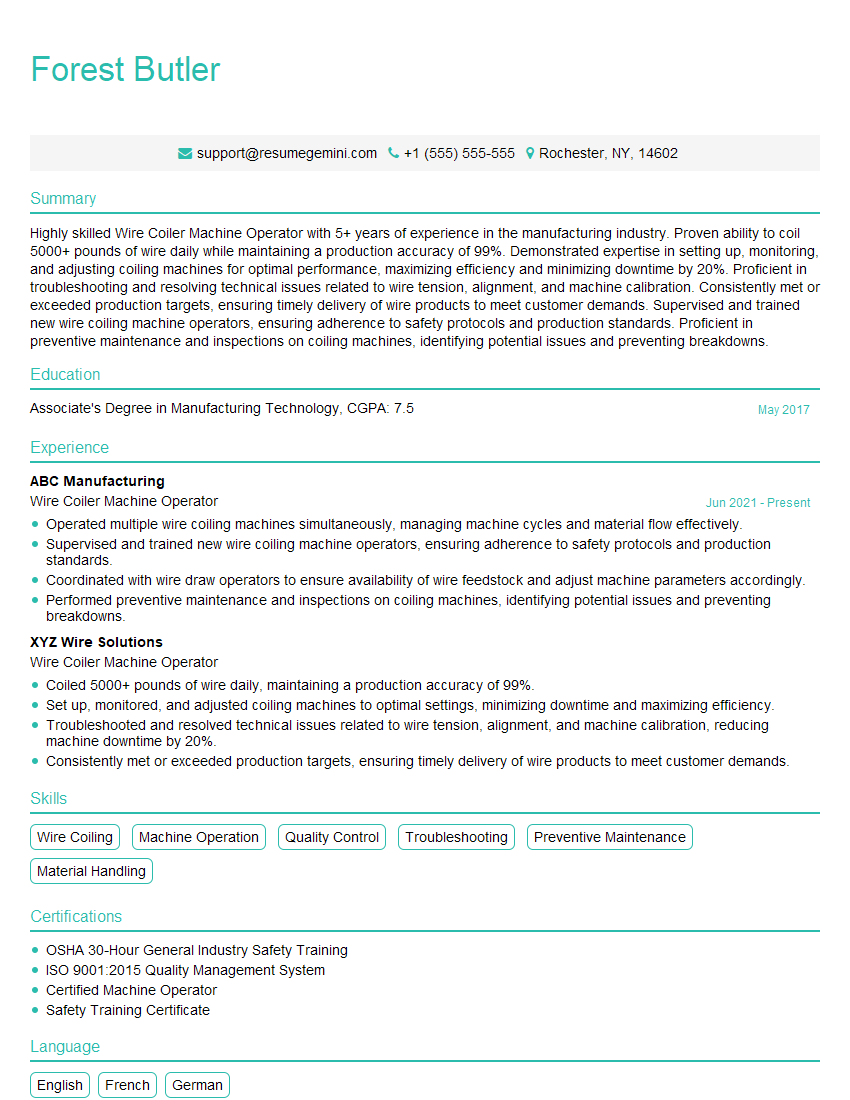

Forest Butler

Wire Coiler Machine Operator

Summary

Highly skilled Wire Coiler Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to coil 5000+ pounds of wire daily while maintaining a production accuracy of 99%. Demonstrated expertise in setting up, monitoring, and adjusting coiling machines for optimal performance, maximizing efficiency and minimizing downtime by 20%. Proficient in troubleshooting and resolving technical issues related to wire tension, alignment, and machine calibration. Consistently met or exceeded production targets, ensuring timely delivery of wire products to meet customer demands. Supervised and trained new wire coiling machine operators, ensuring adherence to safety protocols and production standards. Proficient in preventive maintenance and inspections on coiling machines, identifying potential issues and preventing breakdowns.

Education

Associate’s Degree in Manufacturing Technology

May 2017

Skills

- Wire Coiling

- Machine Operation

- Quality Control

- Troubleshooting

- Preventive Maintenance

- Material Handling

Work Experience

Wire Coiler Machine Operator

- Operated multiple wire coiling machines simultaneously, managing machine cycles and material flow effectively.

- Supervised and trained new wire coiling machine operators, ensuring adherence to safety protocols and production standards.

- Coordinated with wire draw operators to ensure availability of wire feedstock and adjust machine parameters accordingly.

- Performed preventive maintenance and inspections on coiling machines, identifying potential issues and preventing breakdowns.

Wire Coiler Machine Operator

- Coiled 5000+ pounds of wire daily, maintaining a production accuracy of 99%.

- Set up, monitored, and adjusted coiling machines to optimal settings, minimizing downtime and maximizing efficiency.

- Troubleshooted and resolved technical issues related to wire tension, alignment, and machine calibration, reducing machine downtime by 20%.

- Consistently met or exceeded production targets, ensuring timely delivery of wire products to meet customer demands.

Certificates

- OSHA 30-Hour General Industry Safety Training

- ISO 9001:2015 Quality Management System

- Certified Machine Operator

- Safety Training Certificate

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Coiler Machine Operator

- Highlight your experience and skills in wire coiling, machine operation, quality control, troubleshooting, preventive maintenance, and material handling.

- Quantify your accomplishments with specific metrics, such as the number of pounds of wire coiled daily or the percentage of downtime reduced.

- Demonstrate your ability to work independently and as part of a team, and highlight your problem-solving skills and attention to detail.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Wire Coiler Machine Operator Resume

- Coil 5000+ pounds of wire daily, maintaining a production accuracy of 99%.

- Set up, monitor, and adjust coiling machines to optimal settings, minimizing downtime and maximizing efficiency.

- Troubleshoot and resolve technical issues related to wire tension, alignment, and machine calibration, reducing machine downtime by 20%.

- Consistently met or exceeded production targets, ensuring timely delivery of wire products to meet customer demands.

- Supervised and trained new wire coiling machine operators, ensuring adherence to safety protocols and production standards.

- Coordinated with wire draw operators to ensure availability of wire feedstock and adjust machine parameters accordingly.

- Performed preventive maintenance and inspections on coiling machines, identifying potential issues and preventing breakdowns.

Frequently Asked Questions (FAQ’s) For Wire Coiler Machine Operator

What are the key responsibilities of a Wire Coiler Machine Operator?

The key responsibilities of a Wire Coiler Machine Operator include setting up, monitoring, and adjusting coiling machines, troubleshooting and resolving technical issues, meeting production targets, training new operators, coordinating with other departments, and performing preventive maintenance.

What skills are required to be a successful Wire Coiler Machine Operator?

To be a successful Wire Coiler Machine Operator, you need skills in wire coiling, machine operation, quality control, troubleshooting, preventive maintenance, and material handling.

What is the average salary for a Wire Coiler Machine Operator?

The average salary for a Wire Coiler Machine Operator in the United States is around $40,000 per year.

What are the career prospects for Wire Coiler Machine Operators?

Wire Coiler Machine Operators can advance to positions such as Wire Coiling Supervisor, Production Supervisor, or Quality Control Manager.

What are the working conditions like for Wire Coiler Machine Operators?

Wire Coiler Machine Operators typically work in a factory setting, and may be exposed to noise, dust, and fumes.

What is the job outlook for Wire Coiler Machine Operators?

The job outlook for Wire Coiler Machine Operators is expected to be good in the coming years, due to the increasing demand for wire products.