Are you a seasoned Wire Taper seeking a new career path? Discover our professionally built Wire Taper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

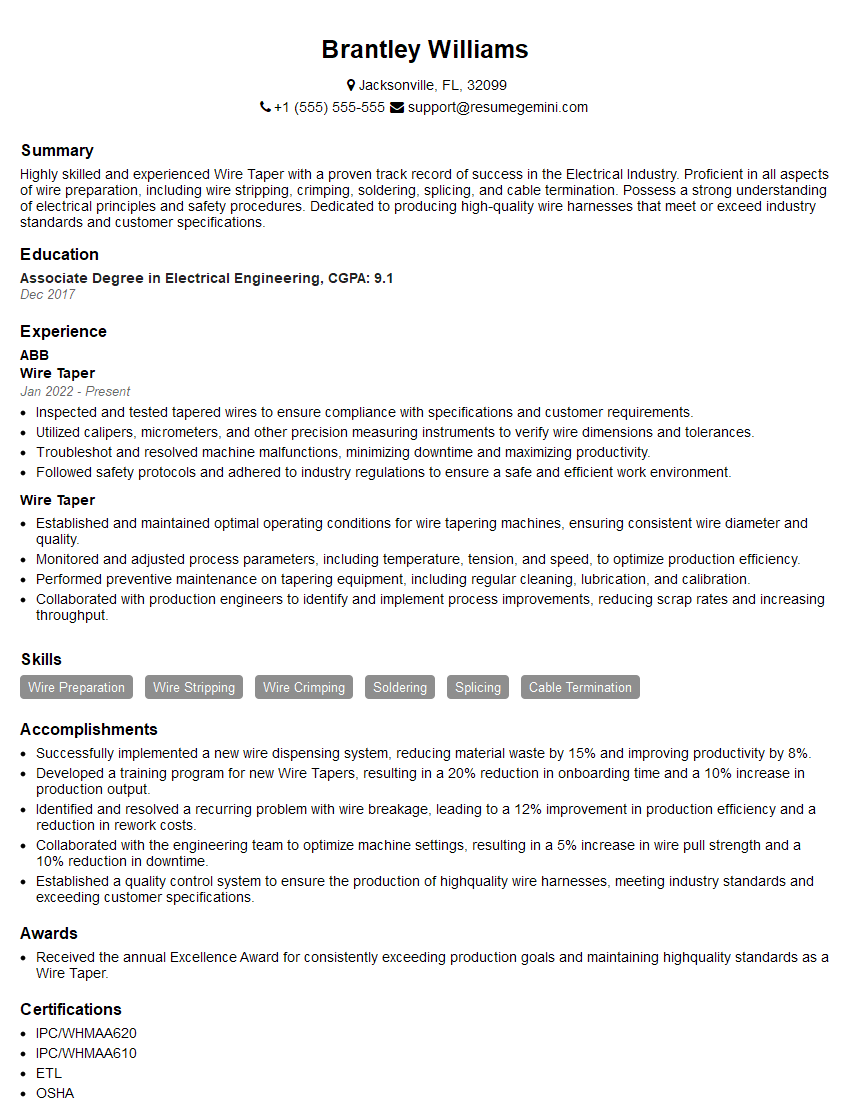

Brantley Williams

Wire Taper

Summary

Highly skilled and experienced Wire Taper with a proven track record of success in the Electrical Industry. Proficient in all aspects of wire preparation, including wire stripping, crimping, soldering, splicing, and cable termination. Possess a strong understanding of electrical principles and safety procedures. Dedicated to producing high-quality wire harnesses that meet or exceed industry standards and customer specifications.

Education

Associate Degree in Electrical Engineering

December 2017

Skills

- Wire Preparation

- Wire Stripping

- Wire Crimping

- Soldering

- Splicing

- Cable Termination

Work Experience

Wire Taper

- Inspected and tested tapered wires to ensure compliance with specifications and customer requirements.

- Utilized calipers, micrometers, and other precision measuring instruments to verify wire dimensions and tolerances.

- Troubleshot and resolved machine malfunctions, minimizing downtime and maximizing productivity.

- Followed safety protocols and adhered to industry regulations to ensure a safe and efficient work environment.

Wire Taper

- Established and maintained optimal operating conditions for wire tapering machines, ensuring consistent wire diameter and quality.

- Monitored and adjusted process parameters, including temperature, tension, and speed, to optimize production efficiency.

- Performed preventive maintenance on tapering equipment, including regular cleaning, lubrication, and calibration.

- Collaborated with production engineers to identify and implement process improvements, reducing scrap rates and increasing throughput.

Accomplishments

- Successfully implemented a new wire dispensing system, reducing material waste by 15% and improving productivity by 8%.

- Developed a training program for new Wire Tapers, resulting in a 20% reduction in onboarding time and a 10% increase in production output.

- Identified and resolved a recurring problem with wire breakage, leading to a 12% improvement in production efficiency and a reduction in rework costs.

- Collaborated with the engineering team to optimize machine settings, resulting in a 5% increase in wire pull strength and a 10% reduction in downtime.

- Established a quality control system to ensure the production of highquality wire harnesses, meeting industry standards and exceeding customer specifications.

Awards

- Received the annual Excellence Award for consistently exceeding production goals and maintaining highquality standards as a Wire Taper.

Certificates

- IPC/WHMAA620

- IPC/WHMAA610

- ETL

- OSHA

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Taper

Quantify your accomplishments.

Use numbers to demonstrate the impact of your work, such as the percentage of reduction in material waste or increase in production efficiency you achieved.Highlight your technical skills.

Employers will be impressed by your proficiency in wire preparation techniques, as well as your knowledge of electrical principles and safety procedures.Emphasize your quality control experience.

Wire Tapers play a critical role in ensuring the quality of electrical assemblies. Highlight your experience in establishing and maintaining quality control systems.Showcase your teamwork skills.

Wire Tapers often work as part of a team. Emphasize your ability to collaborate with others and contribute to the success of the team.

Essential Experience Highlights for a Strong Wire Taper Resume

- Prepare wires for use in electrical assemblies, following specified lengths and color codes.

- Strip insulation from wires using manual or automatic wire strippers.

- Crimp wire terminals and connectors using hand tools or crimping machines.

- Solder wire connections to ensure a strong and reliable electrical connection.

- Splice wires together to extend their length or create branches in a circuit.

- Terminate cables by attaching connectors or lugs to the ends of the wires, ensuring proper connections.

Frequently Asked Questions (FAQ’s) For Wire Taper

What is the role of a Wire Taper?

Wire Tapers are responsible for preparing wires for use in electrical assemblies. This includes stripping insulation from wires, crimping wire terminals and connectors, soldering wire connections, splicing wires together, and terminating cables.

What are the essential skills for a Wire Taper?

Essential skills for a Wire Taper include proficiency in wire preparation techniques, such as wire stripping, crimping, soldering, splicing, and cable termination. Additionally, Wire Tapers should have a strong understanding of electrical principles and safety procedures.

What are the career prospects for a Wire Taper?

Wire Tapers can advance their careers by developing specialized skills, such as proficiency in specific types of electrical equipment or wire preparation techniques. They can also move into supervisory or management roles.

How can I improve my resume for a Wire Taper position?

To improve your resume for a Wire Taper position, focus on quantifying your accomplishments, highlighting your technical skills, emphasizing your quality control experience, and showcasing your teamwork skills.

What are the typical working conditions for a Wire Taper?

Wire Tapers typically work in a manufacturing or production environment. They may be required to work with sharp tools and equipment, and they may be exposed to noise and fumes.