Are you a seasoned Wire Winder seeking a new career path? Discover our professionally built Wire Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

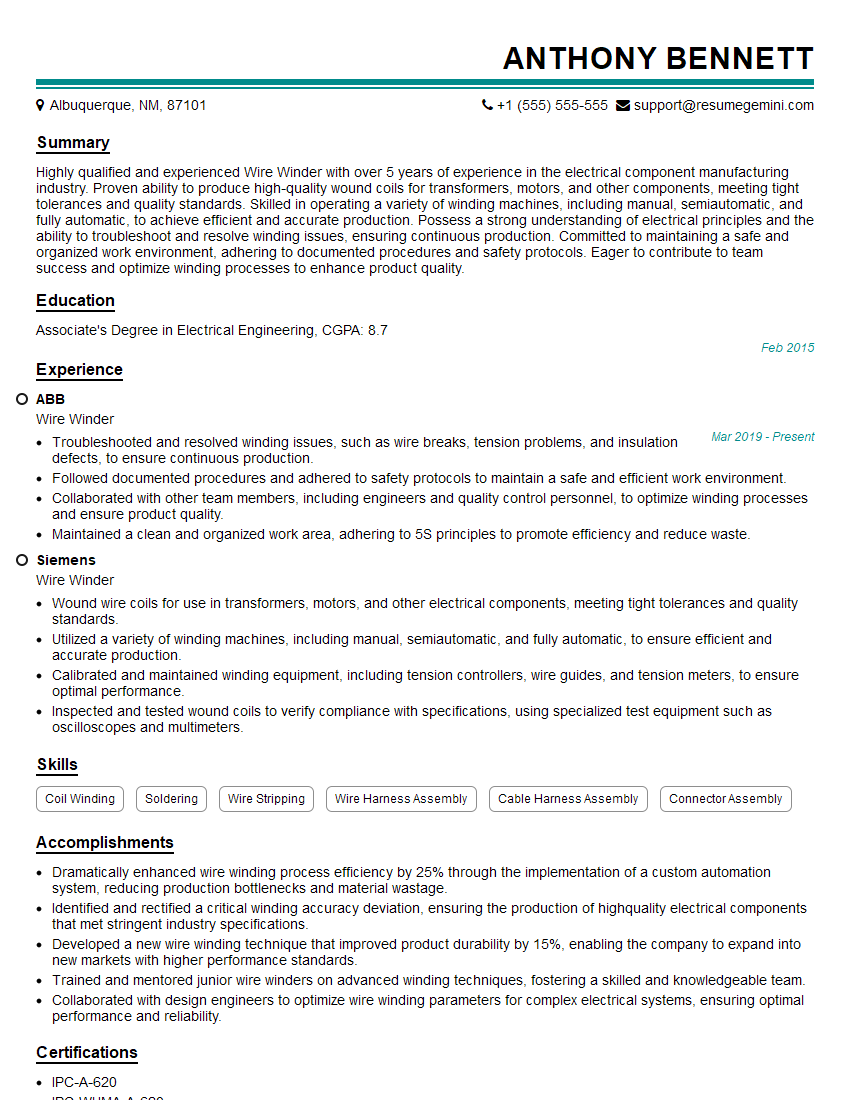

Anthony Bennett

Wire Winder

Summary

Highly qualified and experienced Wire Winder with over 5 years of experience in the electrical component manufacturing industry. Proven ability to produce high-quality wound coils for transformers, motors, and other components, meeting tight tolerances and quality standards. Skilled in operating a variety of winding machines, including manual, semiautomatic, and fully automatic, to achieve efficient and accurate production. Possess a strong understanding of electrical principles and the ability to troubleshoot and resolve winding issues, ensuring continuous production. Committed to maintaining a safe and organized work environment, adhering to documented procedures and safety protocols. Eager to contribute to team success and optimize winding processes to enhance product quality.

Education

Associate’s Degree in Electrical Engineering

February 2015

Skills

- Coil Winding

- Soldering

- Wire Stripping

- Wire Harness Assembly

- Cable Harness Assembly

- Connector Assembly

Work Experience

Wire Winder

- Troubleshooted and resolved winding issues, such as wire breaks, tension problems, and insulation defects, to ensure continuous production.

- Followed documented procedures and adhered to safety protocols to maintain a safe and efficient work environment.

- Collaborated with other team members, including engineers and quality control personnel, to optimize winding processes and ensure product quality.

- Maintained a clean and organized work area, adhering to 5S principles to promote efficiency and reduce waste.

Wire Winder

- Wound wire coils for use in transformers, motors, and other electrical components, meeting tight tolerances and quality standards.

- Utilized a variety of winding machines, including manual, semiautomatic, and fully automatic, to ensure efficient and accurate production.

- Calibrated and maintained winding equipment, including tension controllers, wire guides, and tension meters, to ensure optimal performance.

- Inspected and tested wound coils to verify compliance with specifications, using specialized test equipment such as oscilloscopes and multimeters.

Accomplishments

- Dramatically enhanced wire winding process efficiency by 25% through the implementation of a custom automation system, reducing production bottlenecks and material wastage.

- Identified and rectified a critical winding accuracy deviation, ensuring the production of highquality electrical components that met stringent industry specifications.

- Developed a new wire winding technique that improved product durability by 15%, enabling the company to expand into new markets with higher performance standards.

- Trained and mentored junior wire winders on advanced winding techniques, fostering a skilled and knowledgeable team.

- Collaborated with design engineers to optimize wire winding parameters for complex electrical systems, ensuring optimal performance and reliability.

Certificates

- IPC-A-620

- IPC-WHMA-A-620

- J-STD-001

- ISO 9001

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Winder

- Highlight your proficiency in operating various winding machines and your ability to achieve precise and accurate winding results.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency or quality.

- Emphasize your problem-solving skills and ability to troubleshoot and resolve winding issues, ensuring continuous production.

- Showcase your commitment to safety and your adherence to documented procedures and protocols in a manufacturing environment.

- Consider obtaining industry-recognized certifications, such as IPC-A-610 or IPC/WHMA-A-620, to enhance your credibility and demonstrate your expertise.

Essential Experience Highlights for a Strong Wire Winder Resume

- Wound wire coils for transformers, motors, and other electrical components, adhering to strict quality standards and specifications.

- Utilized a diverse range of winding machines, including manual, semiautomatic, and fully automatic equipment, to optimize production efficiency and accuracy.

- Calibrated and maintained winding equipment, such as tension controllers, wire guides, and tension meters, to ensure optimal performance and produce high-quality coils.

- Inspected and tested wound coils using specialized equipment, such as oscilloscopes and multimeters, to verify compliance with specifications and identify any defects.

- Troubleshooted and resolved winding issues, including wire breaks, tension problems, and insulation defects, to minimize production downtime and maintain high-quality standards.

- Collaborated with engineers and quality control personnel to optimize winding processes, improve product quality, and resolve technical challenges.

Frequently Asked Questions (FAQ’s) For Wire Winder

What are the essential skills required for a successful Wire Winder?

Essential skills for a Wire Winder include proficiency in operating winding machines, attention to detail, ability to follow instructions and specifications precisely, problem-solving skills, and commitment to quality and safety.

What are the typical job responsibilities of a Wire Winder?

Typical responsibilities of a Wire Winder involve winding wire coils for electrical components, operating and maintaining winding machines, inspecting and testing wound coils, troubleshooting and resolving winding issues, and adhering to safety protocols.

What qualifications are required to become a Wire Winder?

While formal education requirements may vary, many Wire Winders possess an Associate’s Degree in Electrical Engineering or a related field, along with hands-on experience in electrical component manufacturing.

What are the potential career paths for a Wire Winder?

With experience and additional training, Wire Winders may advance to roles such as Winding Machine Operator, Production Supervisor, or Quality Control Inspector within the electrical component manufacturing industry.

How can I improve my chances of getting hired as a Wire Winder?

To improve your chances of getting hired as a Wire Winder, focus on developing your technical skills, obtaining industry-recognized certifications, gaining hands-on experience through internships or apprenticeships, and showcasing your commitment to quality and safety in your resume and interviews.

What are some of the challenges faced by Wire Winders?

Common challenges faced by Wire Winders include working with delicate wires and small components, maintaining high levels of precision and accuracy, meeting tight production deadlines, and ensuring compliance with safety regulations.

What is the work environment like for a Wire Winder?

Wire Winders typically work in manufacturing facilities or production environments, often involving repetitive tasks and exposure to machinery and electrical components. Maintaining a clean and organized workspace is essential for safety and efficiency.

Is there a high demand for Wire Winders in the job market?

The demand for Wire Winders can vary depending on the industry and economic conditions. However, skilled and experienced Wire Winders with a strong track record of quality and efficiency are generally in demand within the electrical component manufacturing sector.