Are you a seasoned Woodworking Machinist seeking a new career path? Discover our professionally built Woodworking Machinist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

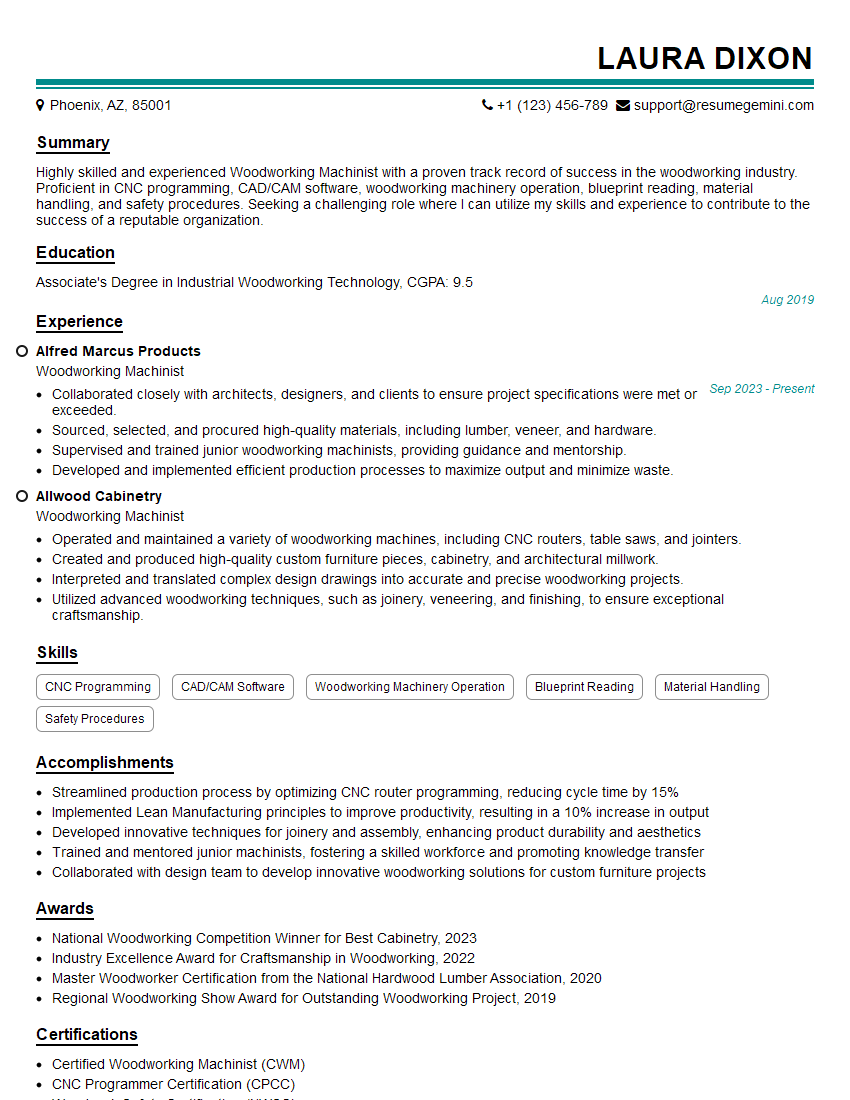

Laura Dixon

Woodworking Machinist

Summary

Highly skilled and experienced Woodworking Machinist with a proven track record of success in the woodworking industry. Proficient in CNC programming, CAD/CAM software, woodworking machinery operation, blueprint reading, material handling, and safety procedures. Seeking a challenging role where I can utilize my skills and experience to contribute to the success of a reputable organization.

Education

Associate’s Degree in Industrial Woodworking Technology

August 2019

Skills

- CNC Programming

- CAD/CAM Software

- Woodworking Machinery Operation

- Blueprint Reading

- Material Handling

- Safety Procedures

Work Experience

Woodworking Machinist

- Collaborated closely with architects, designers, and clients to ensure project specifications were met or exceeded.

- Sourced, selected, and procured high-quality materials, including lumber, veneer, and hardware.

- Supervised and trained junior woodworking machinists, providing guidance and mentorship.

- Developed and implemented efficient production processes to maximize output and minimize waste.

Woodworking Machinist

- Operated and maintained a variety of woodworking machines, including CNC routers, table saws, and jointers.

- Created and produced high-quality custom furniture pieces, cabinetry, and architectural millwork.

- Interpreted and translated complex design drawings into accurate and precise woodworking projects.

- Utilized advanced woodworking techniques, such as joinery, veneering, and finishing, to ensure exceptional craftsmanship.

Accomplishments

- Streamlined production process by optimizing CNC router programming, reducing cycle time by 15%

- Implemented Lean Manufacturing principles to improve productivity, resulting in a 10% increase in output

- Developed innovative techniques for joinery and assembly, enhancing product durability and aesthetics

- Trained and mentored junior machinists, fostering a skilled workforce and promoting knowledge transfer

- Collaborated with design team to develop innovative woodworking solutions for custom furniture projects

Awards

- National Woodworking Competition Winner for Best Cabinetry, 2023

- Industry Excellence Award for Craftsmanship in Woodworking, 2022

- Master Woodworker Certification from the National Hardwood Lumber Association, 2020

- Regional Woodworking Show Award for Outstanding Woodworking Project, 2019

Certificates

- Certified Woodworking Machinist (CWM)

- CNC Programmer Certification (CPCC)

- Woodwork Safety Certification (NWSC)

- Quality Management Certification (QMC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Woodworking Machinist

- Highlight your CNC programming and CAD/CAM software skills, as these are essential for operating modern woodworking machinery.

- Showcase your experience in blueprint reading and interpretation, as this is crucial for understanding and executing complex designs.

- Emphasize your attention to detail and commitment to quality, as these are vital traits for a successful Woodworking Machinist.

- Include any certifications or specialized training that demonstrates your proficiency in woodworking techniques and safety procedures.

Essential Experience Highlights for a Strong Woodworking Machinist Resume

- Operate and maintain a variety of woodworking machinery, including CNC routers, saws, drills, and sanders

- Interpret blueprints, drawings, and specifications to ensure accurate production of wooden components

- Program and operate CNC machines to produce complex shapes and designs

- Set up and adjust machinery to optimize production efficiency and quality

- Inspect finished products to ensure they meet specifications and quality standards

- Maintain a clean and organized work area, and follow all safety protocols

Frequently Asked Questions (FAQ’s) For Woodworking Machinist

What is the primary role of a Woodworking Machinist?

The primary role of a Woodworking Machinist is to operate and maintain woodworking machinery to produce wooden components and products according to specifications.

What are the key skills required to be a Woodworking Machinist?

Key skills for a Woodworking Machinist include CNC programming, CAD/CAM software, woodworking machinery operation, blueprint reading, material handling, and safety procedures.

What industries employ Woodworking Machinists?

Woodworking Machinists are employed in various industries, including furniture manufacturing, cabinetry, construction, and musical instrument production.

What is the job outlook for Woodworking Machinists?

The job outlook for Woodworking Machinists is expected to be positive as there is a growing demand for skilled workers in the manufacturing sector.

What are the potential career paths for Woodworking Machinists?

With experience and additional training, Woodworking Machinists can advance to roles such as Production Supervisor, Quality Control Inspector, or CNC Programmer.

Is there a professional organization for Woodworking Machinists?

Yes, the National Woodworking Machinery Association (NWMA) offers membership and resources for Woodworking Machinists.