Are you gearing up for a career in Compressed Gas Tester? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Compressed Gas Tester and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

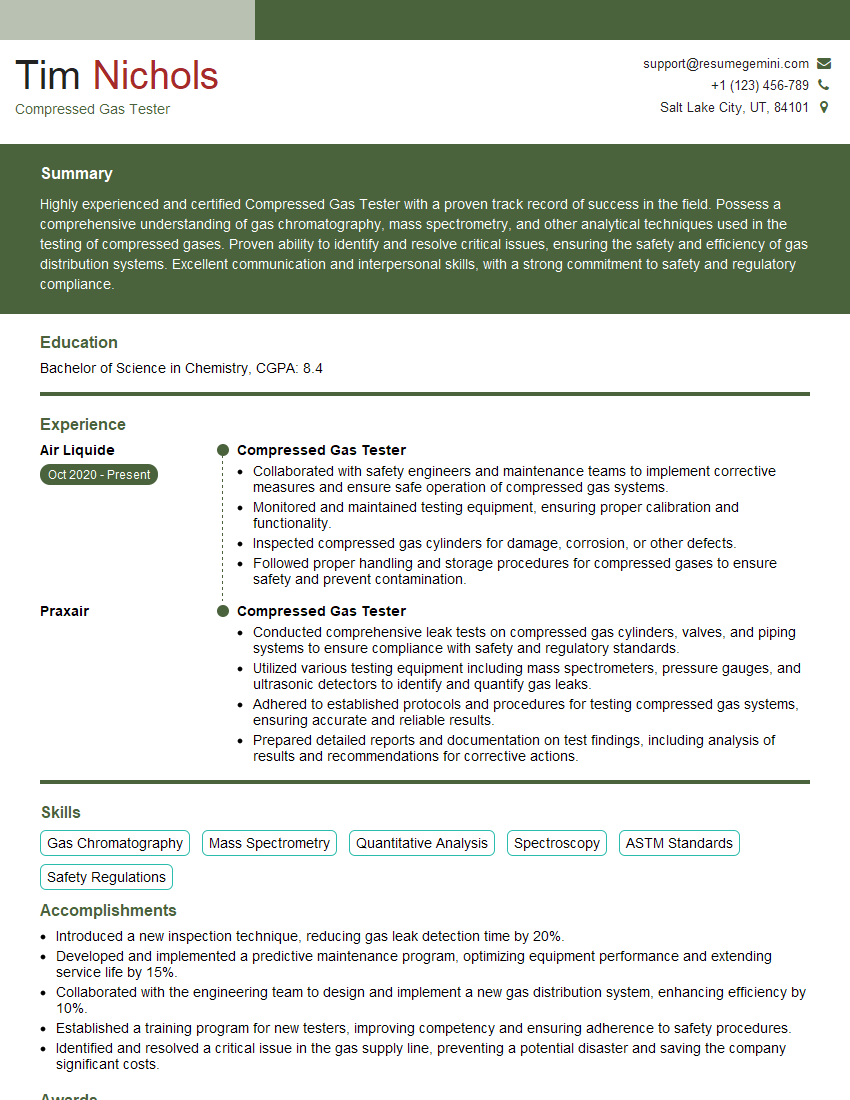

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Compressed Gas Tester

1. What are the various types of compressed gas cylinders and how do you identify them?

The different types of compressed gas cylinders include:

- Type 1: Seamless cylinders made from a single piece of metal without any welded seams.

- Type 2: Welded cylinders made from two or more pieces of metal that are welded together.

- Type 3: Composite cylinders made from a combination of materials, such as metal and fiberglass.

The identification of compressed gas cylinders is based on their color-coding system and gas labeling. Each gas has a specific color assigned to it, which helps in easy identification. Additionally, labels on the cylinders provide information about the gas type, its purity, and other relevant details.

2. Describe the process of conducting a pressure test on a compressed gas cylinder.

Hydrostatic Testing

- The cylinder is filled with water and pressurized to a specified test pressure.

- The cylinder is held at the test pressure for a specified period to identify any leaks or deformations.

- If the cylinder passes the test, it is stamped with a new test date and returned to service.

Pneumatic Testing

- The cylinder is filled with compressed air or nitrogen and pressurized to a specified test pressure.

- The cylinder is held at the test pressure for a specified period to identify any leaks or deformations.

- If the cylinder passes the test, it is stamped with a new test date and returned to service.

3. What are the safety precautions to be observed while handling compressed gas cylinders?

- Store cylinders in a well-ventilated area.

- Secure cylinders upright to prevent them from falling over.

- Use proper regulators and hoses to connect cylinders to equipment.

- Never open a cylinder valve without first attaching the regulator.

- Inspect cylinders regularly for leaks, rust, or damage.

- Train employees on the safe handling of compressed gas cylinders.

4. How do you determine the purity of a compressed gas?

- Gas Chromatography: Analyzes the gas sample and separates different components based on their chemical properties, providing information about their concentration and purity.

- Mass Spectrometry: Determines the molecular weight and abundance of ions in the gas sample, allowing for the identification and quantification of different gas components.

- Gas Analyzer: Employs various techniques, such as electrochemical sensors or optical absorption, to measure the concentration of specific gases in a mixture, providing insights into its purity.

5. What are the common defects found in compressed gas cylinders and how do you inspect them?

- Corrosion: Visual inspection for rust or pitting on the cylinder surface.

- Dents or Bulges: Examination of the cylinder’s shape for any deformations or irregularities.

- Cracks: Non-destructive testing methods like ultrasonic or magnetic particle inspection can detect cracks in the cylinder’s material.

- Valve Defects: Checking the valve for leaks, damage, or any signs of malfunction.

- Hydrostatic Testing: Subjecting the cylinder to a high-pressure water test to assess its structural integrity and identify any weaknesses.

6. Explain the importance of maintaining proper records for compressed gas cylinders.

- Safety: Records track inspections, tests, and repairs, ensuring cylinders meet safety standards.

- Compliance: Documentation demonstrates adherence to regulations and industry best practices.

- Asset Management: Records provide a history of each cylinder, aiding in maintenance planning and optimizing their lifespan.

- Traceability: In case of incidents or recalls, records help trace the distribution and usage of cylinders.

- Legal Liability: Proper records serve as evidence of due diligence, protecting against potential legal issues.

7. Describe the different types of welding gases and their applications.

Shielding Gases

- Argon: Used for welding non-ferrous metals and stainless steel.

- Helium: Provides high heat and penetration for welding thick materials.

- Carbon Dioxide: Suitable for welding mild steel.

Fuel Gases

- Acetylene: Produces a hot, carburizing flame for welding steel.

- Propane: Offers a clean, hot flame for brazing and soldering.

- Hydrogen: Used for welding specific metals like titanium and zirconium.

8. What are the potential hazards associated with working with compressed gases and how can they be mitigated?

- Pressure Hazards: Use pressure regulators, secure cylinders, and train personnel on proper handling.

- Toxic Gases: Ensure proper ventilation, use respirators, and monitor gas levels.

- Flammable Gases: Keep away from ignition sources, use non-sparking tools, and provide adequate ventilation.

- Cryogenic Gases: Handle with insulated gloves and clothing, prevent skin contact, and ensure proper storage and transportation.

- Asphyxiation: Ventilate confined spaces, use gas detectors, and train personnel on emergency procedures.

9. Explain the role of quality control in ensuring the accuracy and reliability of compressed gas testing results.

- Calibrated Equipment: Use calibrated instruments and regularly verify their accuracy.

- Standard Operating Procedures: Establish and follow standardized testing procedures to ensure consistency.

- Sample Integrity: Collect and handle samples properly to maintain their integrity.

- Data Analysis: Analyze data carefully and identify any anomalies or inconsistencies.

- Corrective Actions: Implement corrective actions promptly to address any deviations from established standards.

10. Describe your experience in using different analytical techniques for compressed gas analysis.

I have experience in utilizing various analytical techniques for compressed gas analysis, including:

- Gas Chromatography: Separating and identifying gas components based on their chemical properties.

- Mass Spectrometry: Determining the molecular weight and abundance of ions in gas samples.

- Fourier Transform Infrared (FTIR) Spectroscopy: Identifying and quantifying specific gas compounds based on their infrared absorption patterns.

- Gas Analyzers: Employing electrochemical sensors or optical absorption to measure the concentration of specific gases.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Compressed Gas Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Compressed Gas Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Compressed Gas Tester

Compressed Gas Testers play a crucial role in ensuring the safety and quality of compressed gas products. They are responsible for conducting various tests on compressed gas containers and systems to assess their integrity, composition, and performance. Their key job responsibilities include:

1. Testing and Evaluating Compressed Gas Containers

Testing the strength and integrity of compressed gas containers to ensure they meet industry standards and regulations.

- Conducting hydrostatic and pneumatic tests to check for leaks, cracks, or other structural defects.

- Inspecting valves, fittings, and other components for corrosion, damage, or wear.

2. Analysing Gas Composition and Purity

Analysing the composition and purity of compressed gases to ensure they meet specified standards.

- Using gas chromatography, mass spectrometry, or other analytical techniques to identify and quantify gas components.

- Monitoring contaminants and moisture levels to ensure they do not exceed acceptable limits.

3. Performing Performance and Safety Tests

Conducting performance and safety tests on compressed gas systems to assess their functionality and reliability.

- Testing pressure regulators, valves, and other components to ensure proper operation.

- Evaluating leak rates and flow rates to ensure compliance with industry standards.

4. Maintaining Testing Equipment and Records

Maintaining and calibrating testing equipment to ensure accuracy and reliability.

- Performing routine maintenance, repairs, and calibrations on testing equipment.

- Documenting test results, observations, and any discrepancies or non-conformances.

Interview Preparation Tips for Compressed Gas Testers

To ace an interview for a Compressed Gas Tester position, it is essential to prepare thoroughly and highlight your skills and experience in the field. Here are some tips to help you:

1. Research the Company and Position

Familiarize yourself with the company’s operations, industry reputation, and specific requirements for the Compressed Gas Tester role. This will help you understand their business objectives and the responsibilities you will be expected to fulfill.

- Visit the company’s website and read their press releases, articles, and financial reports.

- Learn about the industry standards and regulations related to compressed gas testing.

2. Practice Answering Common Interview Questions

Study frequently asked interview questions and develop clear, concise answers that showcase your skills and experience. Some common questions you can prepare for include:

- Tell me about your experience in testing compressed gas containers.

- How do you ensure the accuracy and reliability of your testing results?

- What are your strengths and weaknesses as a Compressed Gas Tester?

- Why are you interested in this position and our company?

3. Highlight Your Technical Skills

Emphasize your proficiency in various testing methods and analytical techniques used in compressed gas testing. This could include:

- Hydrostatic and pneumatic testing

- Gas chromatography and mass spectrometry

- Pressure testing and flow rate analysis

4. Demonstrate Your Safety Consciousness

Compressed gas testing involves working with potentially hazardous materials. Stress your commitment to safety and your understanding of industry best practices and regulations. This could include:

- Experience in handling compressed gases safely

- Knowledge of safety protocols and emergency procedures

- Certifications or training in compressed gas safety

5. Be Professional and Enthusiastic

Dress appropriately for the interview and arrive on time. Maintain a professional demeanor throughout the interview, and show enthusiasm for the position and the company. Ask thoughtful questions to show your interest and engagement.

- Prepare a list of questions to ask the interviewer about the company, the position, and the industry.

- Follow up with a thank-you note to express your appreciation for the opportunity to interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Compressed Gas Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.