Feeling lost in a sea of interview questions? Landed that dream interview for Toolroom Checker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Toolroom Checker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

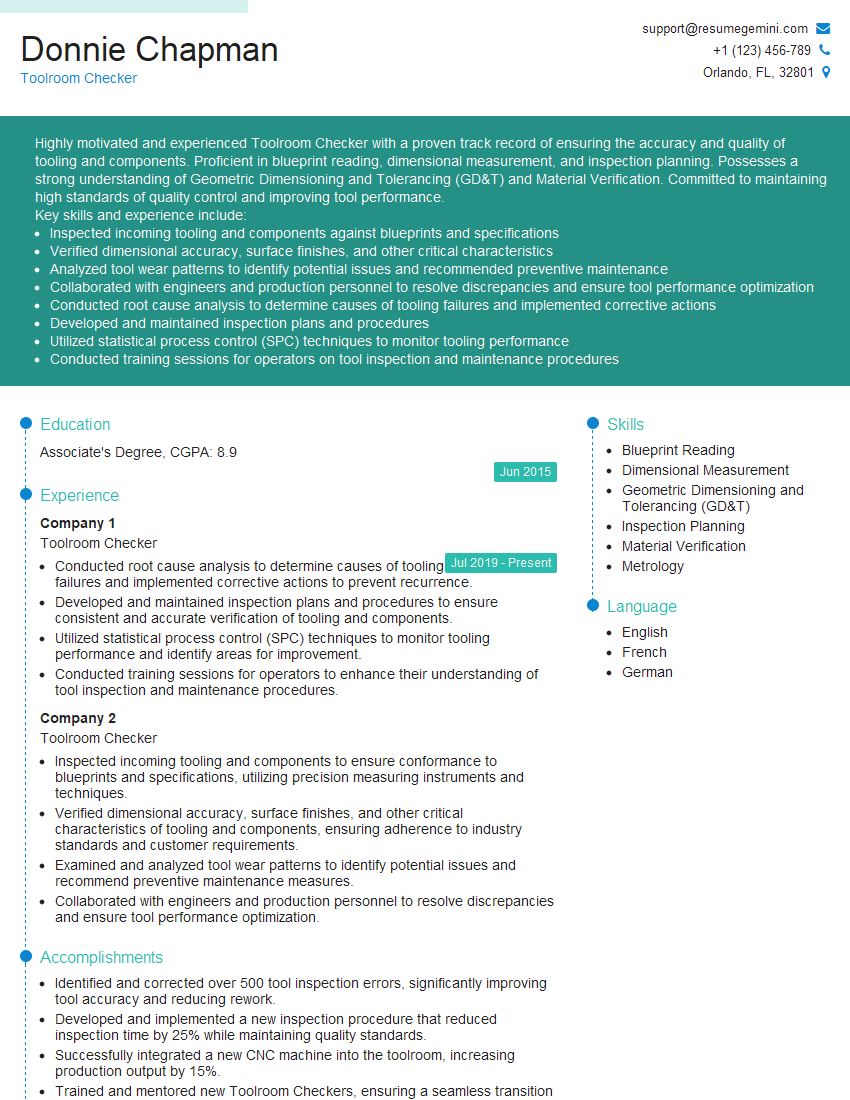

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toolroom Checker

1. Describe the key functions and responsibilities of a Toolroom Checker?

As a Toolroom Checker, I am responsible for ensuring that the tools, equipment, and gauges used in the manufacturing process meet the required specifications and standards. My key functions include:

- Inspecting and verifying the accuracy and functionality of tools, equipment, and gauges using precision measuring instruments

- Identifying and documenting any discrepancies or deviations from the specified tolerances

- Calibrating and adjusting tools and equipment to ensure optimal performance

- Maintaining accurate records of all inspections, calibrations, and adjustments performed

- Collaborating with production teams to identify and resolve any tool-related issues or inefficiencies

2. Explain the different types of measuring instruments used in toolroom checking and their applications?

Dimensional Measurement Instruments

- Calipers (Vernier, Micrometer, Dial): Measure linear dimensions (length, width, height)

- Height Gauges: Determine the height or depth of features

- Coordinate Measuring Machines (CMMs): Measure complex geometries and dimensions in multiple axes

Surface Measurement Instruments

- Surface Plates: Check flatness and surface finish

- Roughness Testers: Measure surface roughness

Angle and Alignment Measurement Instruments

- Protractors: Measure angles

- Levels and Squares: Check for levelness and perpendicularity

- Laser Alignment Systems: Align components and fixtures with high precision

3. Describe the process of calibrating a dial indicator and explain its importance?

Calibrating a dial indicator involves comparing its readings against a known standard or reference. The process typically includes the following steps:

- Setting the indicator to zero on a reference surface

- Using gauge blocks or other precision standards to apply known displacements

- Adjusting the indicator’s scale or dial to match the applied displacements

- Repeating the process at multiple points within the indicator’s range

Calibration is important because it ensures that the indicator provides accurate and reliable measurements, which are crucial for precise toolroom checking and quality control.

4. How do you interpret engineering drawings and specifications to determine the required tolerances and dimensions?

I follow a structured approach to interpreting engineering drawings and specifications:

- Review the drawing title, scale, and overall layout

- Identify the key dimensions and tolerances

- Note any special notes or requirements

- Use measuring instruments appropriate for the specified tolerances

By carefully interpreting the drawings and specifications, I can accurately determine the required dimensions and tolerances, ensuring that tools and equipment meet the design intent.

5. Explain the importance of maintaining accurate records of inspections and adjustments performed?

Accurate records are crucial for several reasons:

- Traceability: Records provide a clear history of inspections and adjustments, allowing for traceability in case of quality issues

- Quality Control: They serve as evidence for the quality of tools and equipment, ensuring compliance with standards and regulations

- Preventive Maintenance: Regular inspections and adjustments help identify potential issues early on, enabling proactive maintenance

- Root Cause Analysis: In the event of tool failures or production problems, records can help identify the root cause and prevent future occurrences

6. Describe your experience with using Statistical Process Control (SPC) techniques in toolroom checking?

I have experience using SPC techniques, such as:

- Control Charts: I create and interpret control charts to monitor tool performance over time and identify trends or deviations

- Process Capability Studies: I conduct process capability studies to determine whether tools and processes are capable of meeting specified tolerances

- Failure Analysis: I use SPC techniques to analyze tool failures and identify potential causes

By applying SPC techniques, I can improve the accuracy and reliability of tools and processes, reduce variability, and enhance overall quality control.

7. How do you stay up-to-date with advancements in toolroom checking technology and best practices?

I stay current with advancements in toolroom checking technology and best practices through:

- Industry Publications: Subscribing to industry magazines and journals

- Conferences and Webinars: Attending industry conferences and participating in online webinars

- Training and Certifications: Pursuing professional development opportunities and obtaining certifications

- Networking: Connecting with other toolroom professionals and sharing knowledge

By staying informed about the latest advancements and best practices, I ensure that I am using the most effective techniques and technologies in my role as a Toolroom Checker.

8. Describe your experience with using computer-aided inspection (CAI) software?

I have experience using CAI software, such as:

- Dimensional Verification: I use CAI software to verify the dimensions of parts and assemblies against CAD models

- Surface Scan Analysis: I utilize CAI software to analyze surface scans for defects and deviations

- Toolpath Verification: I use CAI software to verify CNC toolpaths for accuracy and efficiency

CAI software allows me to automate inspection processes, improve accuracy, and enhance the overall efficiency of toolroom checking.

9. How do you manage multiple tasks and prioritize your workload effectively?

I prioritize my workload by:

- Urgency: Identifying tasks that require immediate attention

- Impact: Assessing the potential impact of each task on overall operations

- Deadlines: Considering established deadlines and timelines

I also use tools and techniques such as:

- Task Lists: Creating organized lists of tasks to track progress

- Time Management Techniques: Applying techniques like the Pomodoro Technique to optimize time allocation

- Delegation: Assigning tasks to appropriate individuals within my team

10. How do you ensure that tools and equipment are properly maintained and calibrated?

I ensure that tools and equipment are properly maintained and calibrated by implementing a comprehensive maintenance program that includes:

- Regular Inspections: Conducting regular inspections to identify potential issues

- Preventive Maintenance: Scheduling preventive maintenance tasks to address potential problems before they occur

- Calibration: Calibrating tools and equipment regularly to maintain accuracy

- Documentation: Maintaining accurate records of all maintenance and calibration activities

By adhering to a structured maintenance program, I ensure that tools and equipment are operating optimally, reducing downtime and enhancing overall productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toolroom Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toolroom Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Toolroom Checkers play a vital role in ensuring the accuracy and quality of manufactured parts. Their key responsibilities include:

1. Inspection and Verification of Parts

Inspect manufactured parts against designated specifications and blueprints, using precision measuring instruments and gauges.

- Measure dimensions, angles, and tolerances with high accuracy.

- Check for surface finish, defects, and adherence to quality standards.

2. Data Analysis and Reporting

Record and analyze inspection results, identifying deviations and discrepancies.

- Prepare inspection reports and provide feedback to production teams.

- Maintain detailed records for quality control and traceability.

3. Tool and Equipment Calibration

Calibrate and maintain measuring instruments and gauges to ensure accuracy and reliability.

- Follow established calibration procedures and schedules.

- Troubleshoot and resolve equipment issues.

4. Quality Control and Process Improvement

Identify and report non-conformances, participate in quality audits, and contribute to process improvement initiatives.

- Recommend corrective actions to address quality issues.

- Collaborate with engineers and production teams to optimize processes.

Interview Tips

Preparing for a Toolroom Checker interview requires a combination of technical knowledge and attention to detail. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s industry, products, and quality standards. Understand the specific requirements of the Toolroom Checker position.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Highlight Your Technical Skills

Emphasize your proficiency in using precision measuring instruments, gauges, and inspection techniques.

- Quantify your experience in conducting dimensional inspections.

- Provide examples of your attention to detail and accuracy.

3. Demonstrate Problem-Solving Abilities

Share instances where you identified discrepancies and implemented corrective actions. Highlight your analytical skills and ability to troubleshoot issues.

- Describe a situation where you identified a quality issue and proposed a solution.

- Explain how you resolved a problem with measuring equipment.

4. Showcase Your Communication Skills

Effective communication is crucial for Toolroom Checkers. Be prepared to discuss your ability to report inspection results, provide feedback, and collaborate with others.

- Give examples of how you effectively communicated quality issues.

- Emphasize your ability to work independently and as part of a team.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare your answers in advance. Use the STAR (Situation, Task, Action, Result) method to structure your responses.

- Why are you interested in this position?

- Describe your experience in quality control.

- How do you ensure the accuracy of your inspections?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Toolroom Checker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.