Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Offset Pressman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

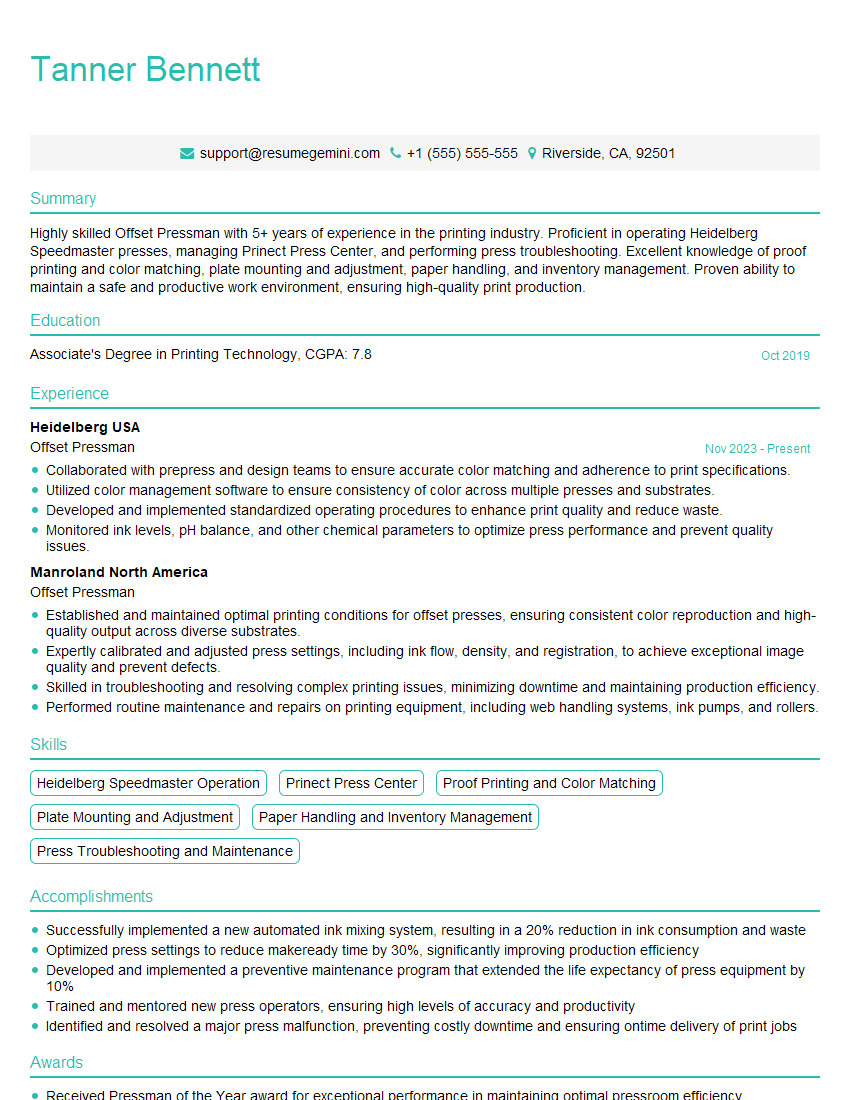

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Offset Pressman

1. What are the different types of offset printing presses?

There are two main types of offset printing presses:

- Sheetfed presses

- Web presses

Sheetfed presses print on individual sheets of paper, while web presses print on a continuous roll of paper.

2. What are the key components of an offset printing press?

Printing unit

- The printing unit is the heart of the press and is responsible for transferring ink from the plate to the paper.

- It consists of a series of rollers that carry the plate, the blanket, and the paper.

Inking system

- The inking system supplies ink to the printing unit.

- It consists of a series of rollers that distribute the ink evenly across the plate.

Dampening system

- The dampening system applies water to the non-image areas of the plate.

- This prevents the ink from sticking to these areas and ensures that the image is transferred cleanly to the paper.

3. What are the different types of printing plates used in offset printing?

The most common types of printing plates used in offset printing are:

- Metal plates

- Polymer plates

- Presensitized plates

Each type of plate has its own advantages and disadvantages, and the best choice for a particular job will depend on the specific requirements.

4. What are the different types of paper used in offset printing?

The most common types of paper used in offset printing are:

- Coated paper

- Uncoated paper

- Newsprint

Coated paper is smoother and has a higher gloss finish than uncoated paper, making it ideal for printing high-quality images.

Uncoated paper is more absorbent and has a more natural look and feel, making it ideal for printing text-heavy documents.

Newsprint is a low-cost paper that is used for printing newspapers and other low-quality publications.

5. What are the different types of printing processes used in offset printing?

The most common types of printing processes used in offset printing are:

- Single-color printing

- Multi-color printing

- Spot color printing

- Process color printing

Single-color printing uses only one ink color, while multi-color printing uses two or more ink colors.

Spot color printing uses pre-mixed inks to create specific colors, while process color printing uses four process colors (cyan, magenta, yellow, and black) to create a wide range of colors.

6. What are the different types of finishing processes used in offset printing?

The most common types of finishing processes used in offset printing are:

- Cutting

- Folding

- Binding

- Laminating

Cutting is used to trim the printed sheets to the desired size.

Folding is used to create brochures, booklets, and other folded products.

Binding is used to secure the printed sheets together into a book or other bound product.

Laminating is used to protect the printed surface from wear and tear.

7. What are the different types of quality control checks performed in offset printing?

The most common types of quality control checks performed in offset printing are:

- Color matching

- Registration

- Dot gain

- Trapping

Color matching is used to ensure that the printed colors match the desired colors.

Registration is used to ensure that the printed images are aligned correctly.

Dot gain is used to measure the amount of ink that spreads on the paper.

Trapping is used to prevent gaps between colors when printing multiple colors.

8. What are the different types of maintenance tasks performed on offset printing presses?

The most common types of maintenance tasks performed on offset printing presses are:

- Cleaning

- Lubrication

- Adjustments

- Repairs

Cleaning is used to remove ink, paper dust, and other debris from the press.

Lubrication is used to keep the moving parts of the press running smoothly.

Adjustments are used to ensure that the press is running properly.

Repairs are used to fix any problems that may occur with the press.

9. What are the different types of safety procedures that must be followed when operating an offset printing press?

The most common types of safety procedures that must be followed when operating an offset printing press are:

- Wear proper clothing and safety gear

- Keep hands away from moving parts

- Do not operate the press if you are tired or under the influence of drugs or alcohol

- Follow all manufacturer’s instructions

10. What are the different types of troubleshooting skills that are required to operate an offset printing press?

The most common types of troubleshooting skills that are required to operate an offset printing press are:

- Be able to identify and solve common problems

- Be able to read and understand technical manuals

- Be able to work independently and as part of a team

- Be able to learn new skills and adapt to changing technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Offset Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Offset Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Offset Pressmen are responsible for the operation and maintenance of complex offset printing presses. They are highly skilled professionals who work closely with other members of the print production team to ensure that the printed products meet the highest standards of quality and accuracy.

1. Printing Press Setup and Operation

Offset Pressmen are responsible for preparing the offset printing presses for operation. This includes setting up the paper, ink, and other supplies, as well as adjusting the press settings to ensure that the printed product meets the desired specifications. Once the press is running, they monitor the process closely and make any necessary adjustments to ensure that the print quality is maintained.

2. Troubleshooting and Maintenance

Offset Pressmen are also responsible for troubleshooting and maintaining the printing presses. They must be able to diagnose problems with the press and take corrective action quickly and efficiently. In addition, they must perform regular maintenance on the press to ensure that it remains in good working order.

3. Quality Control and Inspection

Offset Pressmen are responsible for ensuring that the printed products meet the highest standards of quality. They must be able to inspect the printed product for defects, such as smudging, misregistration, and other imperfections. They must also know how to correct any defects that are found.

4. Communication and Teamwork

Offset Pressmen work closely with other members of the print production team, including the prepress and bindery departments. They must be able to communicate effectively with these other team members to ensure that the printing process is berjalan lancar.

Interview Tips

Prepare thoroughly and practice your answers. Take the time to research the company and the specific job you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. Once you have a good understanding of the company, you can start practicing your answers to common interview questions. There are many resources available online and in books that can help you with this process.

1. Be confident and articulate

When you are confident in your abilities, it shows. Make eye contact with the interviewer, speak clearly and concisely, and be enthusiastic about the job. Articulating your thoughts and ideas in a clear and concise manner will make a positive impression on the interviewer.

2. Highlight your skills and experience

The interviewer wants to know why you are the best candidate for the job. Be sure to highlight your skills and experience that are relevant to the position. Use specific examples to illustrate your abilities, and be prepared to talk about how your skills and experience can benefit the company.

3. Be prepared to answer technical questions

Many offset pressman jobs require a high level of technical skill. Be prepared to answer questions about your experience with different types of printing presses, and be able to discuss your knowledge of printing processes.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the job and the company. It also gives you an opportunity to learn more about the position and the company’s culture. Prepare a few questions to ask the interviewer, and be sure to listen carefully to the answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Offset Pressman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!