Feeling lost in a sea of interview questions? Landed that dream interview for Rubber Compounder Mixer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rubber Compounder Mixer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

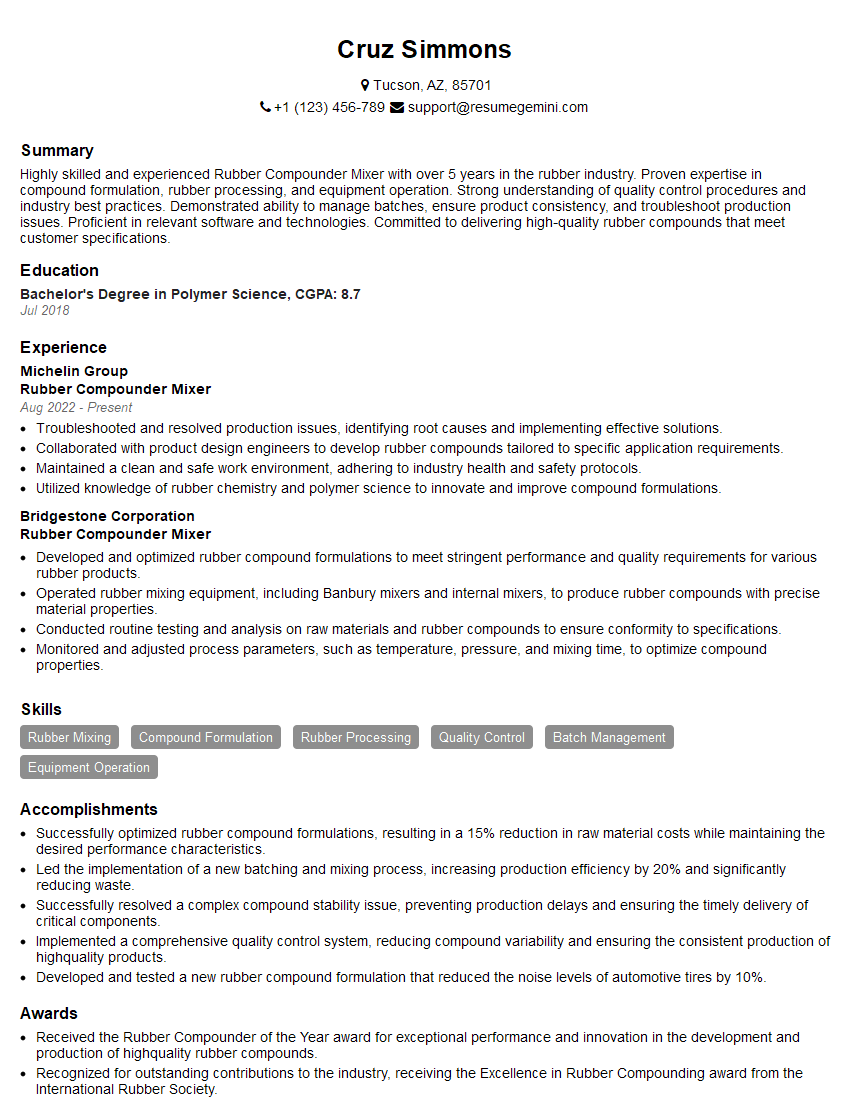

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Compounder Mixer

1. What are the key responsibilities of a Rubber Compounder Mixer?

My key responsibilities include:

- Measuring and mixing raw materials to create rubber compounds.

- Operating Banbury or internal mixers to blend ingredients.

- Monitoring and adjusting mixing parameters, such as temperature, speed, and time.

- Testing rubber compounds to ensure they meet specifications.

- Maintaining and cleaning mixing equipment.

2. How do you ensure the quality and consistency of rubber compounds?

I ensure quality and consistency by:

- Following standard operating procedures and recipes.

- Calibrating and maintaining measuring and mixing equipment.

- Performing regular testing of rubber compounds.

- Documenting mixing parameters and test results.

- Working closely with quality control personnel.

3. What are the common defects in rubber compounds and how do you prevent them?

Common defects include:

- Scorching (overheating during mixing)

- Undermixing (insufficient mixing time)

- Overmixing (excessive mixing time)

- Contamination (foreign particles in the compound)

To prevent these defects, I:

- Monitor mixing parameters carefully.

- Use high-quality raw materials.

- Maintain and clean mixing equipment regularly.

- Follow proper storage and handling procedures.

4. How do you troubleshoot problems in the mixing process?

When troubleshooting problems, I follow a systematic approach:

- Identify the problem and its symptoms.

- Check mixing parameters, equipment, and raw materials.

- Perform tests to identify the root cause.

- Implement corrective actions.

- Monitor the situation to ensure the problem has been resolved.

5. What are the different types of rubber compounds and what are their applications?

There are many different types of rubber compounds, each with its own unique properties and applications. Some common types include:

- Natural rubber: Used in a wide range of products, including tires, hoses, and seals.

- Styrene-butadiene rubber (SBR): Used in tires, shoe soles, and conveyor belts.

- Polybutadiene rubber (BR): Used in tires, hoses, and molded products.

- Ethylene-propylene-diene monomer (EPDM): Used in automotive parts, roofing membranes, and wire insulation.

- Nitrile rubber (NBR): Used in fuel and oil hoses, gaskets, and seals.

6. What are the challenges of working as a Rubber Compounder Mixer and how do you overcome them?

Some challenges include:

- Working with hazardous materials.

- Maintaining a clean and safe work environment.

- Meeting tight production schedules.

- Troubleshooting equipment issues.

I overcome these challenges by:

- Following safety procedures.

- Being organized and efficient in my work.

- Working closely with my team.

- Continuously learning and improving my skills.

7. What are your career goals and how does this position align with them?

My career goals are to:

- Become a highly skilled and experienced Rubber Compounder Mixer.

- Contribute to the success of a leading rubber products company.

- Advance to a supervisory or management role.

This position aligns with my goals by providing me with the opportunity to:

- Gain hands-on experience in rubber compound mixing.

- Work with a team of experienced professionals.

- Contribute to the production of high-quality rubber compounds.

8. What are your strengths and weaknesses?

My strengths include:

- Strong technical skills in rubber compound mixing.

- Attention to detail and quality.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

My weaknesses include:

- Limited experience in supervisory or management roles.

- Can be impatient at times.

9. Why are you interested in working for our company?

I am interested in working for your company because:

- You are a leading rubber products manufacturer.

- You have a strong commitment to quality.

- You offer opportunities for professional development and advancement.

- Your company culture aligns with my values.

10. What questions do you have for me?

I am interested in learning more about:

- The specific challenges and opportunities of this role.

- The company’s plans for growth and expansion.

- The company’s commitment to employee training and development.

- The company’s safety record and procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Compounder Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Compounder Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Compounder Mixers play a vital role in the manufacturing of rubber products. Their key responsibilities include:

1. Preparing Rubber Compounds

Mixers are responsible for preparing rubber compounds according to specified formulas. This involves weighing and measuring various raw materials, such as rubber, fillers, and chemicals, and adding them to a mixing machine.

2. Operating Mixing Equipment

Mixers operate mixing equipment to blend the raw materials thoroughly. They must ensure that the mixture is uniform and free of lumps or voids.

3. Maintaining Equipment

Mixers are responsible for maintaining the mixing equipment in good working order. This includes cleaning the equipment, lubricating moving parts, and making minor repairs.

4. Quality Control

Mixers are responsible for conducting quality control checks on the finished rubber compounds. This involves testing the compounds for properties such as strength, elasticity, and resistance to heat and chemicals.

5. Safety

Mixers must adhere to all safety regulations and wear appropriate protective gear while operating mixing equipment.

Interview Tips

To prepare for an interview for a Rubber Compounder Mixer position, candidates should:

1. Research the Company and Position

Candidates should thoroughly research the company and the specific position they are applying for. This will help them understand the company’s culture, products, and expectations for the role.

2. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as “Tell me about your experience in rubber compounding,” and “What are your strengths and weaknesses?”

3. Prepare Questions for the Interviewer

Candidates should prepare thoughtful questions to ask the interviewer. This shows that they are engaged and interested in the position.

4. Dress Professionally

Candidates should dress professionally for the interview. This means wearing a suit or business casual attire.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rubber Compounder Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rubber Compounder Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.