Are you gearing up for a career in Armature Winder Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Armature Winder Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

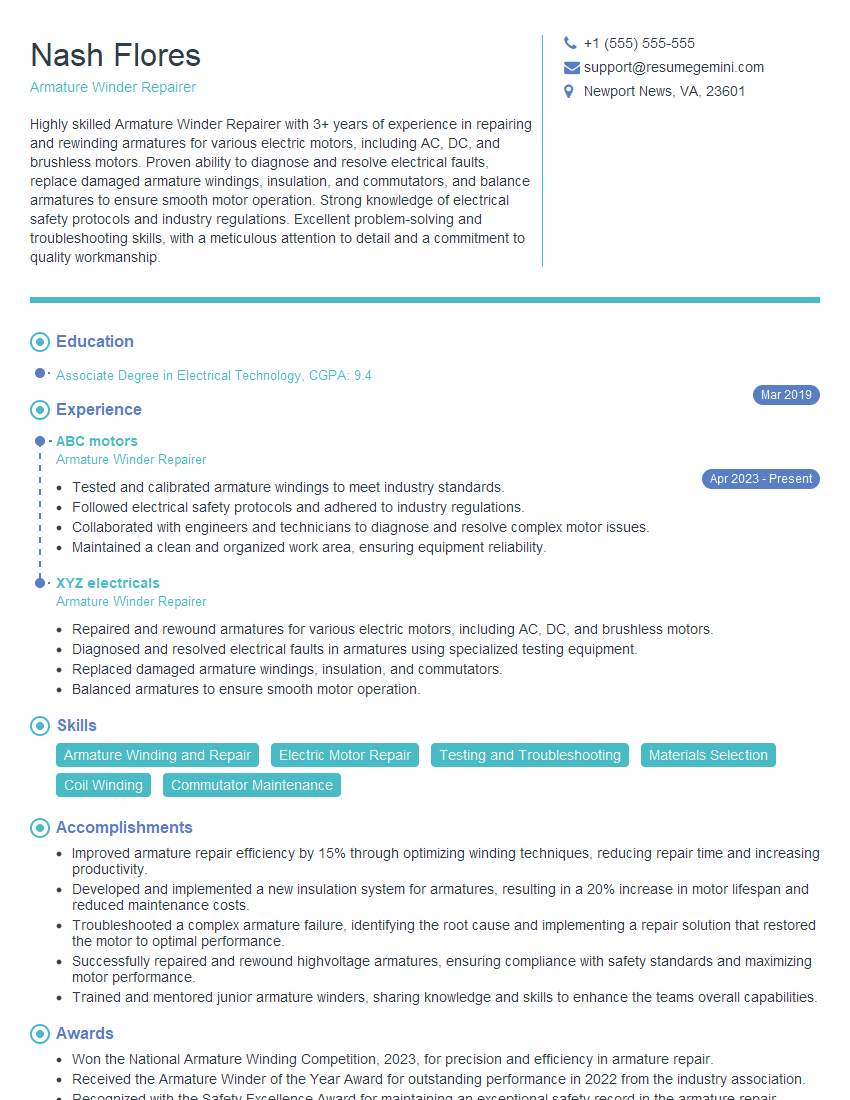

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Armature Winder Repairer

1. Explain the process of rewinding an armature?

The process of rewinding an armature involves the following steps:

- The armature is removed from the motor and disassembled.

- The old windings are removed from the armature.

- The armature is cleaned and inspected for damage.

- New windings are wound onto the armature.

- The armature is reassembled and tested.

2. What are the different types of armature windings?

DC armatures

- Lap winding

- Wave winding

AC armatures

- Single-phase winding

- Two-phase winding

- Three-phase winding

3. What are the factors that can affect the performance of an armature?

- The number of turns in the winding

- The type of wire used

- The pitch of the winding

- The insulation

- The cooling system

4. What are the common problems that can occur with armatures?

- Open windings

- Short windings

- Ground faults

- Armature vibration

- Armature overheating

5. How do you troubleshoot armature problems?

- Inspect the armature for visual damage.

- Test the armature for continuity.

- Test the armature for insulation resistance.

- Measure the armature resistance.

- Use a growler to test for shorted windings.

6. How do you repair armature problems?

- Repair open windings by soldering or welding.

- Repair short windings by cutting out the shorted section and reconnecting the winding.

- Repair ground faults by replacing the insulation.

- Reduce armature vibration by balancing the armature.

- Reduce armature overheating by improving the cooling system.

7. What safety precautions should be taken when working with armatures?

- Wear safety glasses and gloves.

- Use insulated tools.

- Do not touch live wires.

- Do not work on armatures that are connected to a power source.

- Follow all lockout/tagout procedures.

8. What are the different types of armature testing equipment?

- Growlers

- Hipot testers

- Megger testers

- Resistance testers

9. How do you use a growler to test an armature?

- Connect the growler to a power source.

- Place the growler on the armature.

- Listen for any unusual noises.

- If you hear any unusual noises, it is an indication that there is a short in the winding.

10. How do you use a hipot tester to test an armature?

- Connect the hipot tester to the armature.

- Set the hipot tester to the appropriate voltage.

- Apply the voltage to the armature.

- If the armature insulation is good, the hipot tester will not trip.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Armature Winder Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Armature Winder Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Armature Winder Repairers are responsible for maintaining and repairing the armatures used in electric motors and generators. Their key responsibilities include:

1. Repairing armatures

Repairing armatures involves identifying and fixing any damage to the armature, such as broken wires, loose connections, or worn-out insulation.

- Inspecting armatures for damage

- Replacing damaged wires

- Tightening loose connections

- Rewinding armatures

2. Testing armatures

After repairing an armature, it is essential to test it to ensure that it is functioning correctly. This involves running the armature in a test motor and measuring its electrical properties.

- Running armatures in a test motor

- Measuring armature resistance

- Measuring armature voltage

- Measuring armature current

3. Balancing armatures

Armatures must be balanced to ensure that they run smoothly and efficiently. Balancing involves adjusting the weight distribution of the armature so that it does not vibrate excessively.

- Measuring armature vibration

- Adjusting armature weight distribution

- Balancing armatures using a balancing machine

4. Maintaining armature winding equipment

Armature Winder Repairers must also maintain the equipment used to wind armatures, such as winding machines and tensioners. This involves cleaning and lubricating the equipment, as well as making minor repairs.

- Cleaning winding machines

- Lubricating winding machines

- Making minor repairs to winding machines

- Calibrating winding machines

Interview Tips

To ace an interview for an Armature Winder Repairer position, it is important to be well-prepared and knowledgeable about the job. Here are some tips to help you prepare:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Look for news articles or other information about the company

2. Review your skills and experience

Take some time to review your skills and experience, and how they relate to the requirements of the job. Highlight any relevant skills or experience that you have, and be prepared to talk about them in detail.

- Make a list of your skills and experience

- Identify the skills and experience that are most relevant to the job

- Prepare examples of how you have used your skills and experience in the past

3. Prepare answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” or “What are your strengths and weaknesses?” Prepare answers to these questions in advance, and practice delivering them confidently.

- Make a list of common interview questions

- Prepare answers to each question

- Practice delivering your answers out loud

4. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you a chance to learn more about the job and the company culture.

- Prepare a list of questions to ask the interviewer

- Ask questions that are relevant to the job and the company

- Be prepared to answer questions about your own questions

5. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Dress in business attire

- Arrive on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Armature Winder Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.