Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cupola Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

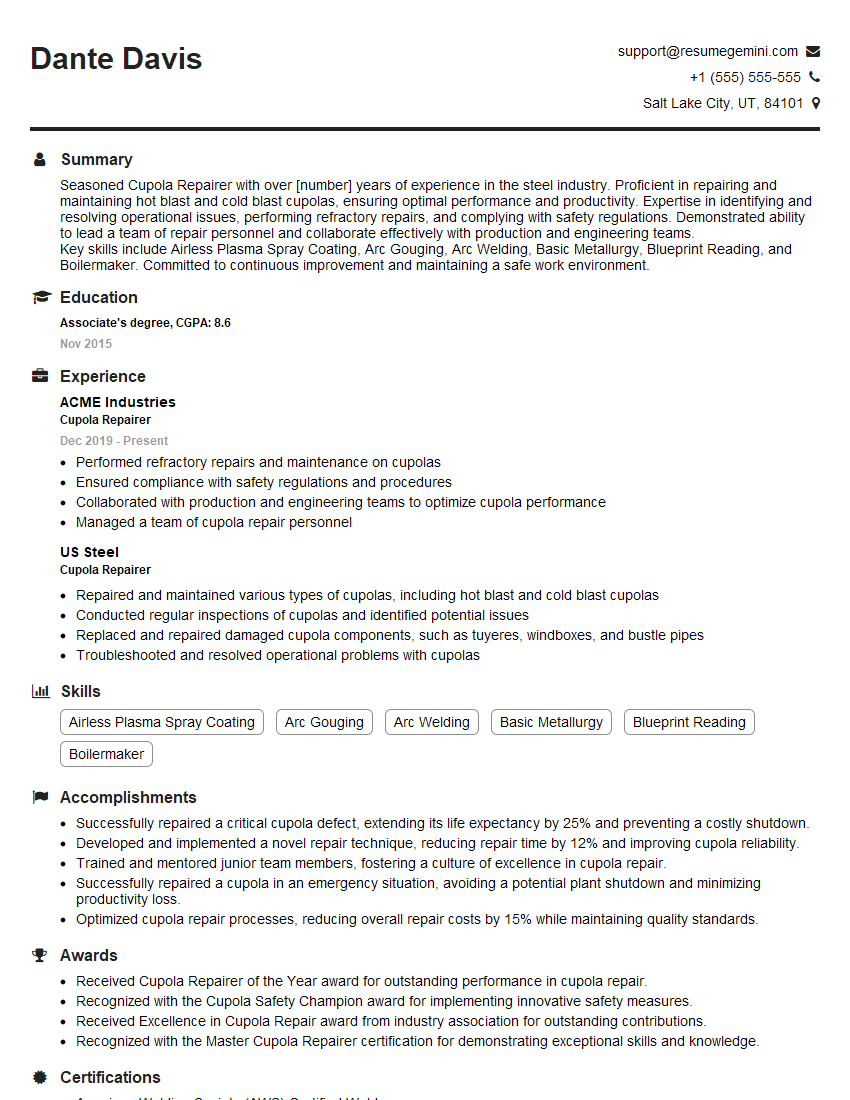

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Repairer

1. Explain the process of repairing a cupola?

In repairing a cupola, I start by inspecting the damage, assessing its severity and identifying the required repair materials. The next step is safety precautions, which involve wearing the necessary protective gear and ensuring the work area is hazard-free. I then proceed to prepare the damaged area, which includes cleaning, removing any loose materials, and shaping the area for optimal bonding. The next step is applying the repair material, which involves selecting the appropriate material based on the damage, mixing it properly, and applying it to the damaged area using appropriate techniques. Once the repair material is applied, I let it cure and set, ensuring proper bonding. Finally, I inspect the repaired area to ensure it meets the required standards and is ready for use.

2. What are the different types of materials used in cupola repair?

There are various materials used in cupola repair, each with its unique properties:

- Refractory cement: Heat-resistant cement used for patching, bonding, and repairing refractory linings.

- Refractory mortar: A mixture of refractory cement and aggregate, providing high-temperature resistance and abrasion resistance.

- Castable refractory: A pre-mixed refractory material used for casting and shaping complex shapes.

- Plastic refractory: A moldable material used for patching, shaping, and repairing refractory linings.

- Ramming mass: A granular material that is compacted into place to form refractory linings.

3. What safety precautions should be taken when repairing a cupola?

When repairing a cupola, safety is paramount, and several precautions must be taken:

- Wear appropriate protective gear: This includes a hard hat, safety glasses, gloves, and protective clothing to prevent injuries from hot materials, sparks, and debris.

- Ensure proper ventilation: Adequate ventilation is crucial to prevent exposure to harmful fumes and dust generated during the repair process.

- Follow electrical safety protocols: Ensure that electrical equipment is properly grounded and in good working condition to prevent electrical hazards.

- Use fall protection gear: When working at heights, use proper fall protection equipment such as harnesses and lifelines to prevent falls.

- Be aware of hot surfaces: Cupolas can retain heat for extended periods. Always check for hot surfaces before touching or working near them to avoid burns.

4. What are the common challenges faced in cupola repair?

Cupola repair presents several challenges:

- Extreme heat: Cupolas operate at high temperatures, which can make it challenging to work on them while they are in operation.

- Confined spaces: Cupolas often have limited access, making it difficult to maneuver and perform repairs in tight quarters.

- Complex shapes: Cupolas can have intricate shapes, which requires careful planning and the use of specialized equipment to repair.

- Refractory materials: Refractory materials used in cupola repair require specific handling and installation techniques to ensure proper bonding and performance.

- Time constraints: Cupola repairs often need to be completed quickly to minimize downtime and production losses.

5. Explain the importance of proper bonding in cupola repair?

Proper bonding in cupola repair is critical for several reasons:

- Structural integrity: Strong bonding ensures that the repaired area maintains its structural integrity and can withstand the stresses and temperatures encountered during cupola operation.

- Preventing leaks: Proper bonding prevents leaks or gas escape from the cupola, ensuring efficient operation and preventing safety hazards.

- Extending lifespan: Well-bonded repairs can extend the lifespan of the cupola by preventing premature failure due to weak or compromised bonding.

- Minimizing downtime: Durable and well-bonded repairs reduce the need for frequent maintenance and repairs, minimizing downtime and maximizing production.

6. Describe the different inspection techniques used to assess cupola damage?

To assess cupola damage, different inspection techniques are employed:

- Visual inspection: A thorough visual examination of the cupola’s interior and exterior surfaces to identify visible cracks, damage, or wear.

- Infrared thermography: Using an infrared camera to detect temperature variations, which can indicate potential damage or defects.

- Ultrasonic testing: Sending ultrasonic waves through the cupola’s structure to identify internal flaws or voids.

- Acoustic emission monitoring: Listening for acoustic emissions or sounds generated by cracks or other damage propagating within the cupola.

- Magnetic particle testing: Applying magnetic particles to the cupola’s surface to detect surface cracks or defects.

7. What are the key factors to consider when selecting the appropriate repair material for a cupola?

Selecting the appropriate repair material for a cupola involves considering several key factors:

- Temperature resistance: The material must be able to withstand the high operating temperatures of the cupola.

- Chemical resistance: The material must be resistant to the corrosive or erosive gases and liquids present in the cupola.

- Strength and durability: The material must possess sufficient strength and durability to handle the mechanical stresses and wear encountered in the cupola.

- Bonding properties: The material must have good bonding characteristics to ensure a strong and lasting repair.

- Compatibility: The material must be compatible with the existing refractory materials used in the cupola.

8. Explain the importance of proper curing and drying of repair materials in cupola repair?

Proper curing and drying of repair materials in cupola repair are crucial for several reasons:

- Strength development: Curing and drying allow the repair materials to develop their full strength and properties, ensuring a durable repair.

- Moisture removal: Removing moisture from the repair materials prevents steam or gas pockets from forming, which can weaken the bond and cause premature failure.

- Preventing cracking: Gradual curing and drying minimize the risk of cracks or damage to the repair materials due to rapid temperature changes or moisture expansion.

- Ensuring proper bonding: Curing and drying allow the repair materials to properly bond with the existing refractory materials, creating a strong and long-lasting repair.

9. Describe the different methods used to monitor the condition of a repaired cupola?

Monitoring the condition of a repaired cupola can be done through various methods:

- Regular visual inspections: Conducting routine visual inspections of the repaired area to check for any signs of damage, cracks, or wear.

- Infrared thermography: Using an infrared camera to detect temperature variations, which can indicate potential issues or damage in the repaired area.

- Ultrasonic testing: Performing ultrasonic testing to identify any internal flaws or defects that may have developed after the repair.

- Acoustic emission monitoring: Listening for acoustic emissions or sounds generated by cracks or other damage propagating in the repaired area.

- Performance monitoring: Tracking the cupola’s performance parameters, such as temperature or pressure, to assess any changes or abnormalities that may indicate underlying issues.

10. Explain the importance of documentation in cupola repair?

Documentation in cupola repair is crucial for several reasons:

- Tracking repairs: Detailed documentation helps keep track of all repairs performed on the cupola, including the date, materials used, and any observations made.

- Historical reference: Maintaining accurate records provides a historical reference for future repairs or troubleshooting, allowing for quick retrieval of information about previous work.

- Quality control: Documentation facilitates quality control by providing a means to review the repair process, identify areas for improvement, and ensure compliance with standards.

- Safety and liability: Proper documentation serves as a legal record of the repair work performed, protecting both the repairer and the facility in case of any incidents or disputes.

- Knowledge sharing: Well-documented repairs can be used as a valuable resource for training new repairers and sharing best practices within the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The primary role of a Cupola Repairer is to ensure the seamless functioning of a cupola furnace, a critical component in the production of ferrous and non-ferrous metals. Their responsibilities encompass various aspects of cupola repair and maintenance.

1. Inspection and Assessment

Cupola Repairers meticulously inspect cupolas to identify areas requiring repair or replacement. They assess the condition of refractory linings, metal jackets, and other components, using specialized tools and techniques.

2. Refractory Maintenance and Repair

A crucial task for Cupola Repairers is the repair and maintenance of refractory linings. They use specialized tools and materials to patch, seal, or replace damaged refractory linings, ensuring the proper insulation and protection of the cupola from extreme temperatures.

3. Metal Jacket Fabrication and Installation

In cases where metal jackets require repair or replacement, Cupola Repairers fabricate and install new jackets. They use welding, cutting, and shaping techniques to ensure a precise fit and optimal performance of the cupola.

4. Safety Protocols and Compliance

Cupola Repairers prioritize safety and adhere to strict protocols to prevent accidents. They wear appropriate protective gear, follow established procedures, and maintain a clean and organized work area.

Interview Tips

To ace an interview for a Cupola Repairer position, candidates should prepare thoroughly by understanding the key job responsibilities and showcasing their skills and experience.

1. Research the Company and Industry

Candidates should research the company and the foundry industry to demonstrate their interest and knowledge. Familiarizing themselves with the company’s operations, products, and safety practices will make a positive impression.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience in cupola repair and maintenance. Quantifying their accomplishments with specific examples and metrics will help them stand out.

3. Prepare for Technical Questions

Interviewers may ask technical questions about cupola operations, refractory materials, and repair techniques. Candidates should prepare by reviewing industry publications and studying common problems encountered in cupola maintenance.

4. Demonstrate Safety Awareness and Compliance

Safety is paramount in a foundry environment. Candidates should highlight their understanding of safety protocols, including the use of protective gear and adherence to established procedures.

5. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows engagement and interest. Candidates should inquire about the company’s safety initiatives, quality standards, and opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cupola Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.