Are you gearing up for a career in Cut Pressman? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cut Pressman and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

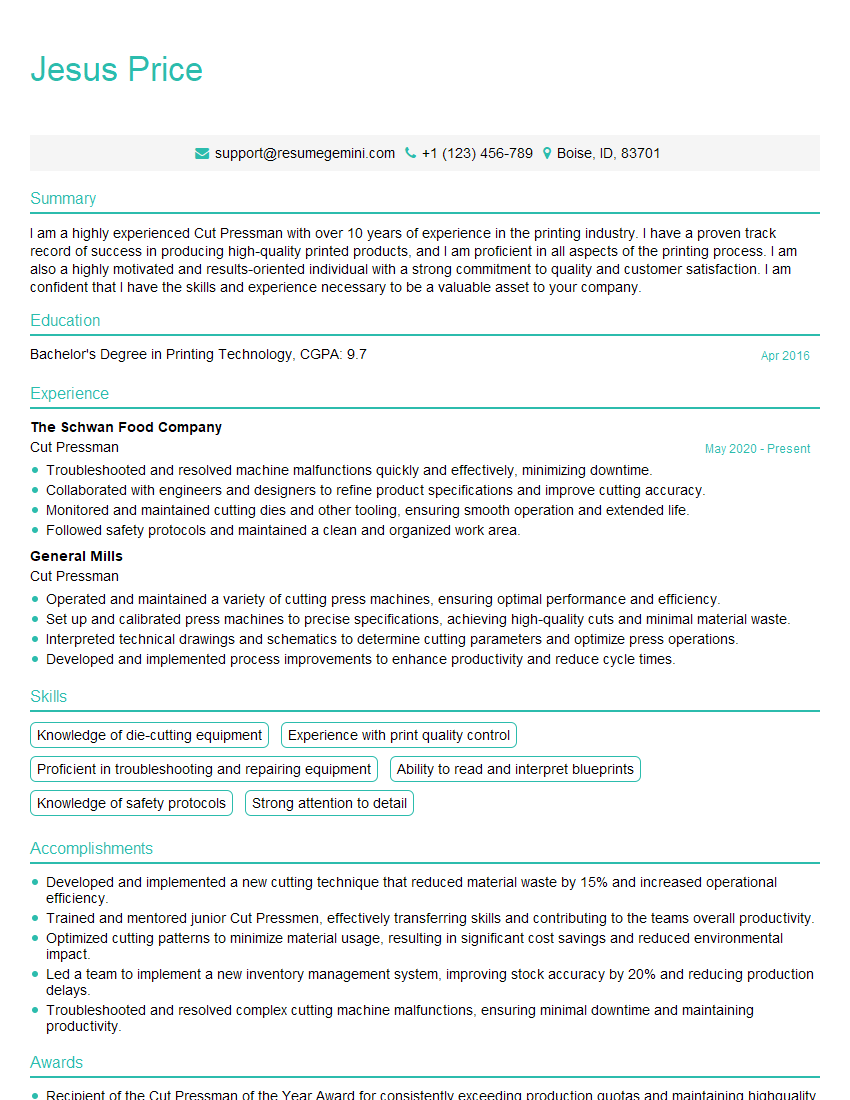

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut Pressman

1. How do you determine the correct settings for a cutting press based on the material and thickness being cut?

To determine the correct settings for a cutting press, I consider the following factors:

- Material Type: Different materials have varying hardness and shear strengths. I consult material data sheets or industry standards to determine appropriate cutting forces.

- Material Thickness: Thicker materials require higher cutting forces. I calculate the required force based on the material’s thickness and shear strength.

- Press Capacity: I verify that the cutting press is capable of delivering the required cutting force. If necessary, I may adjust the press settings or use a different machine.

2. Describe the process of setting up and operating a cutting press.

Safety Precautions

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and free from electrical hazards.

- Inspect the press for any damage or wear before operating.

Setup

- Select the appropriate cutting tool based on the material and thickness.

- Secure the cutting tool in the press and adjust the cutting height.

- Position the material on the cutting table and align it with the cutting tool.

Operation

- Start the press and apply the cutting force gradually.

- Monitor the cutting process and adjust the force or cutting speed as needed.

- Once the cut is complete, release the cutting force and remove the cut material.

3. How do you troubleshoot and resolve common cutting press issues?

Common cutting press issues include:

- Tool breakage: Ensure the tool is sharp and properly secured. Check the material hardness and adjust cutting force if necessary.

- Cutting inaccuracies: Verify the cutting tool alignment and adjust if needed. Inspect the material for any defects or inconsistencies.

- Machine vibration: Tighten all bolts and connections. Check for any unbalanced parts or excessive wear.

- Hydraulic leaks: Inspect the hydraulic system for any leaks. Tighten fittings and replace damaged hoses or seals.

4. What are the safety precautions that must be followed when operating a cutting press?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the machine is properly grounded and free from electrical hazards.

- Inspect the press for any damage or wear before operating.

- Never operate the press with loose clothing or jewelry.

- Keep hands and fingers clear of the cutting area.

- Do not attempt to override safety devices or interlocks.

5. How do you maintain a cutting press to ensure optimal performance and longevity?

- Regular Cleaning: Keep the press clean and free from metal shavings or debris.

- Lubrication: Follow manufacturer’s guidelines for lubrication of moving parts.

- Tool Sharpening: Sharpen cutting tools regularly to maintain cutting accuracy.

- Inspections: Conduct periodic inspections to identify any potential problems, such as loose bolts or worn parts.

- Preventive Maintenance: Schedule regular preventive maintenance to minimize downtime and extend the lifespan of the press.

6. What is the role of hydraulics in a cutting press?

- Force Generation: Hydraulic systems provide the necessary force to cut through materials.

- Pressure Control: Hydraulics allow for precise control of cutting force, which is essential for cutting different materials and thicknesses.

- Speed Control: Hydraulics enable control of the cutting speed, which can be adjusted to optimize cutting performance.

- Power Transmission: Hydraulic systems effectively transmit power from the motor to the cutting tool.

7. Describe the different types of cutting press tools and their applications.

- Rotary Shears: Used for straight cuts on thin sheet metal and plastics.

- Guillotine Shears: Ideal for cutting thicker materials, producing clean and precise cuts.

- Notching Tools: Create notches or slots in materials.

- Bending Tools: For bending and forming materials to desired shapes.

- Punching Tools: Used to create holes or perforations in materials.

8. How do you calculate the force required for a cutting press operation?

- Shear Strength: Determine the shear strength of the material being cut.

- Material Thickness: Measure the thickness of the material.

- Cutting Length: Calculate the total length of the cut.

- Cutting Force: Multiply the shear strength by the material thickness and cutting length.

9. What are the factors that affect the quality of a cutting press operation?

- Tool Sharpness: Sharp tools produce clean and precise cuts.

- Material Condition: Defects or inconsistencies in the material can affect cut quality.

- Cutting Force: Applying the correct force ensures optimal cut quality.

- Tool Alignment: Proper alignment of the cutting tool is essential for accurate cuts.

- Machine Calibration: Regularly calibrating the press ensures accurate cutting performance.

10. How do you minimize waste and optimize material usage in cutting press operations?

- Material Planning: Plan cutting patterns to maximize material utilization.

- Nesting Software: Use software to optimize part placement and reduce wasted material.

- Remnant Utilization: Reuse scrap materials for smaller cuts or other applications.

- Efficient Tooling: Select cutting tools that minimize material deformation and waste.

- Operator Training: Ensure operators are trained to optimize cutting processes and minimize waste.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut Pressman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut Pressman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cut Pressmen are printing professionals who operate cutting machinery to section printed materials into specified sizes and shapes. They play a crucial role in the production process, ensuring accuracy and quality control throughout. Their key job responsibilities include:

1. Machine Operation

Cut Pressmen are responsible for operating various cutting machines, including guillotine, die-cutting, and rotary cutting machines. They must possess proficiency in setting up, calibrating, and maintaining these machines to achieve precise cuts.

- Set up cutting machines based on job specifications

- Calibrate machines for accurate cutting

- Monitor and maintain machines for optimal performance

2. Material Handling

Cut Pressmen handle a wide range of materials, from paper and cardboard to plastics and textiles. They must be meticulous in handling these materials to prevent damage or waste.

- Load and unload materials onto cutting machines

- Inspect materials for defects or imperfections

- Adjust cutting settings based on material type

3. Cutting and Finishing

Cut Pressmen perform cutting operations to produce printed materials in the required sizes and shapes. They must ensure precision and accuracy in their cuts, as well as attention to detail in finishing processes.

- Execute cutting operations according to job specifications

- Monitor cutting process to ensure accuracy

- Finish cut materials, including trimming, creasing, and folding

4. Quality Control

Cut Pressmen are responsible for maintaining quality standards throughout the cutting process. They must inspect materials and finished products for defects and ensure compliance with specifications.

- Inspect cut materials for accuracy and quality

- Identify and resolve any defects or deviations from specifications

- Maintain records of cutting operations for quality control purposes

Interview tips for Cut Pressman

To ace your interview for a Cut Pressman position, consider the following tips and preparation strategies:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Cut Pressman position you are applying for. This will help you understand their business, culture, and the specific requirements of the role.

- Visit the company website and review their mission, values, and products/services.

- Read industry publications and news articles to stay abreast of current trends and advancements.

- Look up the specific job description and note the key responsibilities and qualifications required.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your relevant experience and skills that align with the Cut Pressman job requirements. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

- Discuss your experience in operating cutting machines, specifying the types of machines you have worked with.

- Provide examples of your proficiency in handling different materials and ensuring accuracy in your cuts.

- Mention any quality control measures you have implemented or adhered to in previous roles.

3. Showcase Your Attention to Detail

Cut Pressmen must possess a high level of attention to detail. In the interview, provide examples that demonstrate your meticulous nature and ability to focus on precision.

- Describe situations where you successfully identified and corrected errors in cutting operations.

- Explain your processes for inspecting materials and finished products to ensure quality.

- Discuss your methods for maintaining and calibrating cutting machines for optimal performance.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. It is also an opportunity to clarify any details about the role or the company.

- Inquire about the company’s quality control standards and how they are maintained.

- Ask about the company’s plans for future growth or advancements in cutting technology.

- Request more information about the specific responsibilities and expectations of the Cut Pressman role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cut Pressman role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.