Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ladle Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

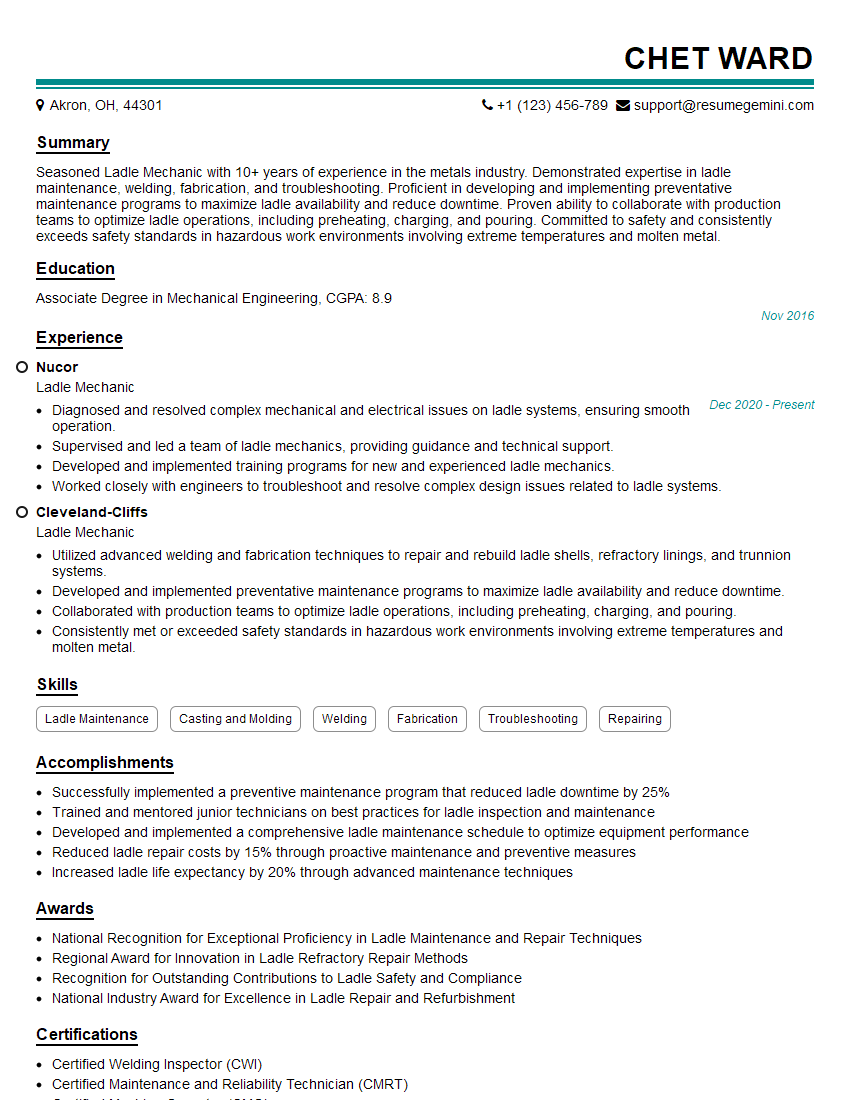

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Mechanic

1. What are the key responsibilities of a Ladle Mechanic?

As a Ladle Mechanic, my primary responsibilities would involve:

- Performing routine maintenance and repairs on ladles, including relining, welding, and mechanical repairs.

- Inspecting ladles for wear and tear, identifying potential issues, and taking corrective actions.

- Ensuring that ladles meet operational safety standards and regulations.

- Operating cranes and other equipment to move and position ladles.

- Collaborating with other maintenance personnel to troubleshoot and resolve complex issues.

2. Describe the process of relining a ladle.

Understanding the Ladle Structure

- Identify the type of ladle and its components.

- Assess the extent of damage or wear to the lining.

Preparation and Removal

- Remove existing lining using jackhammers or other tools.

- Clean and prepare the ladle shell for relining.

Refractory Installation

- Select appropriate refractory materials based on ladle type and operating conditions.

- Install refractory bricks or castables using specialized techniques.

Curing and Inspection

- Cure the lining according to manufacturer’s specifications.

- Inspect the relined ladle for any defects or inconsistencies.

3. What are the common types of welding used in ladle maintenance?

In ladle maintenance, the following welding techniques are commonly employed:

- MIG Welding: Used for welding thinner materials and creating high-quality welds with minimal spatter.

- TIG Welding: Offers precise welds with a clean finish, suitable for working with stainless steel and aluminum.

- Arc Welding: A versatile technique used for welding thicker materials, providing strong and durable joints.

- Plasma Cutting: Used to cut and shape metal using a high-temperature plasma arc, resulting in clean edges.

4. How do you ensure the safety of personnel during ladle maintenance operations?

Safety is paramount during ladle maintenance. To ensure personnel safety, I adhere to the following measures:

- Proper Equipment: Ensure that all personnel wear appropriate PPE, including fire-resistant clothing, gloves, and respirators.

- Area Inspection: Conduct thorough inspections of the work area before starting any maintenance activities.

- Isolation and Lockout: Isolate the ladle from electrical and mechanical sources, and lock out all equipment prior to maintenance.

- Ventilation: Provide adequate ventilation to remove hazardous fumes and gases.

- Emergency Preparedness: Establish clear emergency procedures and ensure that all personnel are familiar with them.

5. What maintenance records should be kept for ladles?

Maintaining accurate records is crucial for tracking ladle maintenance history and ensuring compliance.

- Inspection Logs: Document regular inspections, including dates, findings, and any corrective actions taken.

- Repair Records: Detailed records of all repairs performed, including materials used, techniques employed, and the date of completion.

- Lining History: Track the installation and replacement of ladle linings, noting the materials used, dates, and any issues encountered.

- Equipment Calibration Records: Maintain records of regular calibration and maintenance of equipment used for ladle maintenance.

- Safety Inspections: Document safety inspections conducted before and after each maintenance activity.

6. What are the key factors to consider when choosing a ladle refractory material?

Selecting the appropriate ladle refractory material is crucial for ensuring ladle longevity and performance. Key factors to consider include:

- Operating Environment: The temperature, chemical composition, and slag conditions that the ladle will encounter.

- Ladle Type: The size, shape, and application of the ladle.

- Refractory Properties: The thermal conductivity, chemical resistance, and mechanical strength of the refractory material.

- Cost and Availability: The economic considerations and the availability of the refractory material.

- Industry Standards: Complying with established industry standards and best practices for ladle refractory selection.

7. Describe the procedure for troubleshooting a ladle that is leaking.

When troubleshooting a leaking ladle, I follow a systematic approach:

- Safety First: Ensure the area is safe and all personnel are protected.

- Identify Leakage Source: Determine the exact location of the leak using visual inspection, temperature readings, or ultrasonic testing.

- Assess Severity: Evaluate the extent of the leak and its potential impact on operations.

- Temporary Repairs: If possible, implement temporary measures to contain the leak and prevent further damage.

- Root Cause Analysis: Identify the underlying cause of the leak, such as lining failure, structural damage, or equipment malfunction.

- Permanent Repairs: Develop and execute a plan for permanent repairs, addressing the root cause and restoring the ladle’s integrity.

8. How do you handle situations where you encounter unexpected problems during ladle maintenance?

Handling unexpected problems during ladle maintenance requires a calm and methodical approach:

- Assess the Situation: Quickly evaluate the problem and its potential impact on safety and operations.

- Communicate Effectively: Inform supervisors and colleagues of the issue and seek their input.

- Explore Solutions: Brainstorm and consider various options to address the problem.

- Implement Solutions: Select the most feasible solution and proceed with caution.

- Monitor and Adjust: Continuously monitor the situation and make necessary adjustments to the solution as needed.

9. What software or technology do you utilize to enhance your ladle maintenance operations?

In addition to traditional maintenance techniques, I utilize the following software and technology to improve efficiency and accuracy:

- Computerized Maintenance Management Systems (CMMS): Track maintenance schedules, work orders, and spare parts inventory.

- Predictive Maintenance Tools: Monitor equipment data and identify potential issues before they escalate.

- Non-Destructive Testing (NDT) Equipment: Perform inspections using ultrasonic testing, radiography, and other NDT techniques to detect hidden defects.

- Augmented Reality (AR) and Virtual Reality (VR): Use AR/VR for remote assistance, training, and visualization of maintenance procedures.

- Data Analytics: Analyze maintenance data to identify trends, improve processes, and optimize ladle performance.

10. How do you stay updated with the latest advancements in ladle maintenance techniques?

To ensure I remain proficient in the latest ladle maintenance techniques, I engage in the following activities:

- Attending Industry Conferences and Webinars: Participate in events to learn about new technologies, best practices, and industry trends.

- Reading Technical Journals and Publications: Stay informed about research and developments in ladle maintenance.

- Networking with Other Professionals: Connect with peers and experts to share knowledge and exchange ideas.

- Seeking Professional Development Opportunities: Enroll in courses, workshops, or certifications to enhance my skills.

- Staying Informed about Regulatory Changes: Monitor industry regulations and standards to ensure compliance and adherence to best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ladle Mechanics play a crucial role in maintaining and repairing ladles, which are used for transporting and pouring molten metal in metalworking industries. Their primary responsibilities include:

1. Maintenance and Repair:

Inspecting, diagnosing, and repairing ladles and related equipment, including ladle linings, pouring spouts, and refractory materials.

- Replacing worn or damaged parts

- Reconditioning ladles to extend their lifespan

2. Installation and Commissioning:

Installing new ladles and associated equipment, ensuring proper alignment and functionality.

- Testing and commissioning ladles to meet operational specifications

- Providing technical support to operators during commissioning

3. Predictive Maintenance:

Conducting regular inspections and assessments to identify potential problems and perform preventive maintenance.

- Monitoring ladle performance and wear patterns

- Developing and implementing predictive maintenance plans

4. Safety and Environmental Compliance:

Ensuring ladles and equipment meet safety and environmental regulations.

- Adhering to proper handling and storage procedures for hazardous materials

- Implementing environmental protection measures to minimize emissions

Interview Tips

To ace an interview for a Ladle Mechanic position, candidates can follow these tips:

1. Research the Company and Role:

Thoroughly research the company’s history, industry, and specific requirements for the Ladle Mechanic role.

- Visit the company website and read about their products, services, and culture

- Study the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience:

Emphasize your technical skills and experience in ladle maintenance, repair, and installation.

- Quantify your accomplishments with specific examples

- Describe projects or situations where you demonstrated problem-solving abilities and attention to detail

3. Demonstrate Safety and Environmental Awareness:

Highlight your understanding of safety protocols and environmental regulations related to ladle operations.

- Explain your experience in implementing safety measures and minimizing environmental impact

- Demonstrate your knowledge of industry best practices and standards

4. Prepare for Technical Questions:

Understand the technical aspects of ladle operations and be prepared to answer questions about:

- Ladle materials, construction, and design

- Refractory lining installation and maintenance

- Pouring spout mechanisms and control systems

5. Be Enthusiastic and Professional:

Demonstrate your passion for the iron and steel industry and your commitment to delivering high-quality work.

- Be polite, respectful, and maintain eye contact throughout the interview

- Ask thoughtful questions to show your interest and engagement

Next Step:

Now that you’re armed with the knowledge of Ladle Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ladle Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini