Are you gearing up for an interview for a Microfilm Processor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Microfilm Processor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

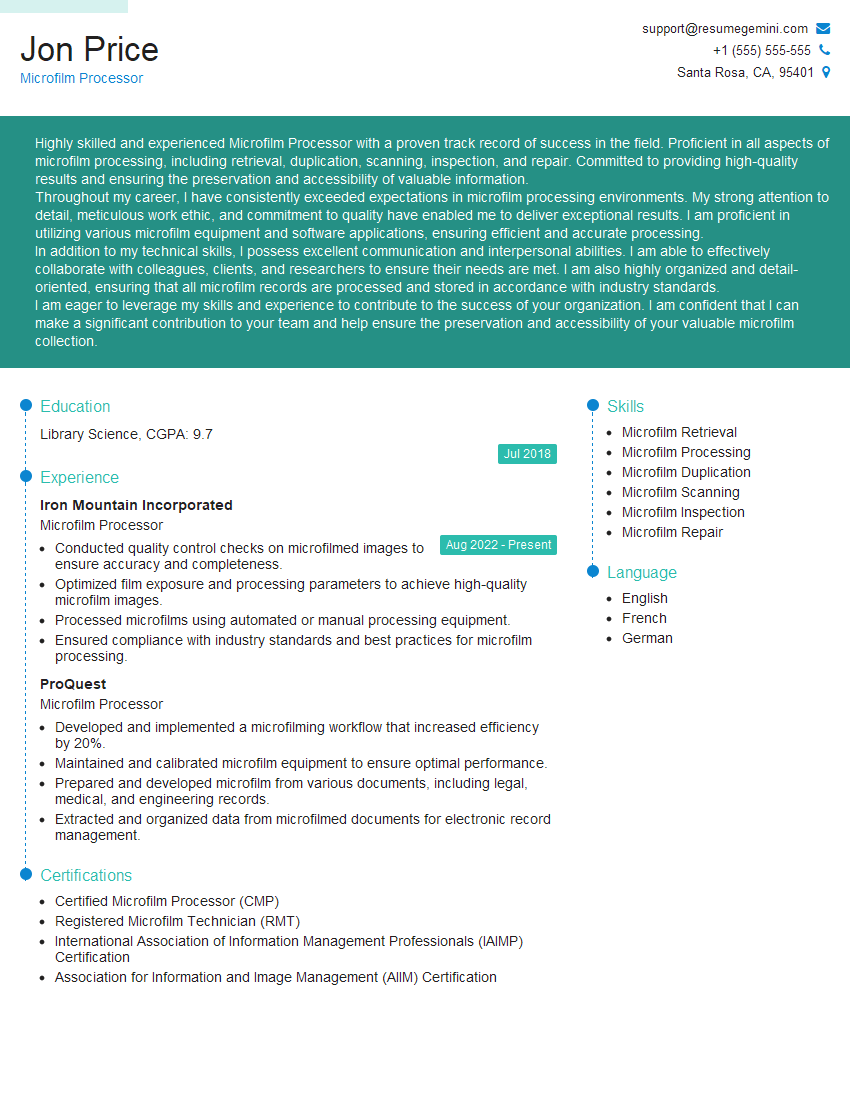

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Microfilm Processor

1. Describe the basic principle of Microfilm technology?

Microfilm technology involves capturing and storing images, typically text or drawings, on a roll of film. To create microfilm, a camera is used to reduce the original document to a size that can be accommodated on the film. The film is then developed, which makes the image permanent.

2. Explain the difference between positive and negative microfilm?

Positive microfilm has a dark image on a light background, similar to the original document. Negative microfilm, on the other hand, has a light image on a dark background.

Positive microfilm is more commonly used because it’s easier to read and print from. Negative microfilm, however, can be more durable and is often used for long-term storage and preservation purposes.

3. What are the advantages of using Microfilm over other storage methods?

Microfilm has several advantages over other storage methods, including:

- Space-saving: Microfilm is significantly more compact than paper, allowing for more efficient storage and organization.

- Durability: Microfilm is a highly durable material that can withstand handling, storage, and environmental factors.

- Longevity: Microfilm can last for decades without deteriorating, making it an ideal medium for long-term document preservation.

- Security: Microfilm is less susceptible to theft or unauthorized access compared to digital or paper-based records.

- Cost-effective: Microfilm storage is generally more cost-effective than other methods, especially when considering the long-term preservation and maintenance costs.

4. Explain the process of Microfilm scanning?

Microfilm scanning involves converting the images stored on microfilm to a digital format. This process typically includes the following steps:

- Preparation: The microfilm is mounted onto a specialized scanner.

- Scanning: The scanner captures images from the microfilm using a CCD or CIS sensor.

- Image processing: The scanned images are processed to enhance their quality, remove noise, and adjust contrast and brightness.

- Digital output: The processed images are saved in a digital format, typically as TIFF, JPG, or PDF files.

5. What factors affect the quality of Microfilm images?

Several factors can affect the quality of microfilm images, including:

- Original document quality: The quality of the original document directly impacts the quality of the microfilm image.

- Camera and film type: The camera and film used to create the microfilm play a significant role in image quality.

- Processing and storage conditions: The processing and storage conditions of the microfilm can affect its durability and image quality.

- Scanning equipment and techniques: The type of scanner and scanning techniques used for digital conversion can influence the quality of the resulting images.

6. Describe the key components of a Microfilm Processor?

The key components of a Microfilm Processor include:

- Transport mechanism: This mechanism moves the microfilm through the processor at a controlled speed.

- Developing station: This station applies the developer solution to the exposed microfilm, making the image visible.

- Fixing station: This station applies a fixer solution to the developed microfilm to stop the development process and make the image permanent.

- Washing station: This station removes the developer and fixer solutions from the microfilm.

- Drying station: This station dries the washed microfilm to prevent damage and prepare it for storage or scanning.

7. Explain the importance of proper chemical balance in Microfilm Processing?

Proper chemical balance is essential in Microfilm Processing to ensure optimal image quality and longevity. The concentrations of developer, fixer, and other solutions must be carefully maintained to achieve the desired results.

Incorrect chemical balance can lead to problems such as:

- Poor image quality: Unbalanced chemicals can result in insufficient development or incomplete fixing, affecting image clarity and contrast.

- Film damage: Improper chemical balance can cause damage to the microfilm, such as fading, staining, or brittleness.

- Reduced longevity: Unbalanced chemicals can shorten the lifespan of the microfilm, making it more susceptible to deterioration and loss of data.

8. How do you troubleshoot common problems encountered in Microfilm Processing?

Common problems in Microfilm Processing include:

- Poor image quality: This can be caused by factors such as incorrect chemical balance, exposure issues, or damage to the microfilm.

- Film damage: This can occur due to improper handling, chemical imbalances, or mechanical problems in the processor.

- Processor malfunctions: These can range from minor issues like sensor errors to more severe problems like mechanical breakdowns.

Troubleshooting involves identifying the root cause of the problem and taking appropriate corrective actions, such as:

- Adjusting chemical balance

- Inspecting and cleaning the processor

- Calibrating sensors and components

- Replacing damaged parts

9. What safety precautions should be observed when working with Microfilm Processing chemicals?

Microfilm Processing chemicals can be hazardous and require careful handling to ensure safety. Precautions include:

- Protective gear: Always wear gloves, eye protection, and a lab coat when handling chemicals.

- Proper ventilation: Ensure adequate ventilation in the work area to prevent inhalation of chemical fumes.

- Chemical storage: Store chemicals in designated areas and follow proper disposal procedures.

- Spill response: Have a plan in place for handling chemical spills and accidental contact.

- Training: Ensure that all personnel handling chemicals are properly trained and aware of safety protocols.

10. How do you maintain and calibrate Microfilm Processing equipment?

Regular maintenance and calibration are crucial for optimal performance and longevity of Microfilm Processing equipment. Maintenance tasks include:

- Cleaning: Regularly clean the processor, rollers, and components to prevent dirt and debris buildup.

- Lubrication: Lubricate moving parts as per the manufacturer’s recommendations.

- Sensor calibration: Calibrate sensors regularly to ensure accurate measurements and image quality.

- Processor calibration: Periodically calibrate the processor to maintain consistent image density and processing times.

- Preventive maintenance: Conduct regular inspections and preventive maintenance to identify and address potential issues before they become major problems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Microfilm Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Microfilm Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Microfilm Processor is responsible for operating, maintaining, and repairing microfilm processing equipment. They play a vital role in converting original documents into microfilm for long-term storage and retrieval.

1. Microfilm Processing and Development

Process and develop microfilm rolls or microfiche using specialized equipment.

- Load microfilm into the processor and adjust processing parameters.

- Monitor the processing cycle to ensure proper development and fixing.

2. Equipment Maintenance and Calibration

Perform routine maintenance on microfilm processors, including cleaning, lubrication, and adjustment.

- Inspect and replace worn or damaged parts to maintain optimal performance.

- Calibrate equipment regularly to ensure accurate processing and image quality.

3. Quality Control and Troubleshooting

Inspect processed microfilm for defects and ensure compliance with quality standards.

- Troubleshoot and resolve processing problems to minimize errors and maintain high-quality output.

- Maintain processing logs and documentation to track performance and identify areas for improvement.

4. Management of Microfilm Archives

Manage and store processed microfilm archives for long-term preservation and retrieval.

- Organize and label microfilm rolls or microfiche for easy access and retrieval.

- Maintain environmental controls to ensure optimal storage conditions and prevent deterioration.

Interview Tips

To succeed in your interview for the Microfilm Processor role, consider the following tips:

1. Research the Company and Industry

Gather information about the organization, its products and services, and the microfilm industry. This will demonstrate your interest and enthusiasm for the position.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating, maintaining, and troubleshooting microfilm processing equipment. Provide specific examples of your experience in these areas.

3. Showcase Your Quality Control Expertise

Discuss your understanding of microfilm processing quality standards and your ability to inspect and identify defects. Explain your approach to troubleshooting and resolving issues.

4. Demonstrate Your Attention to Detail

Microfilm processing requires precise attention to detail. Highlight your ability to follow procedures meticulously and maintain a clean and organized work environment.

5. Prepare for Problem-Solving Scenarios

Be prepared to discuss potential processing problems that you have encountered and how you resolved them. This will demonstrate your analytical thinking and problem-solving skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Microfilm Processor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.