Feeling lost in a sea of interview questions? Landed that dream interview for Porcelain Enameler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Porcelain Enameler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

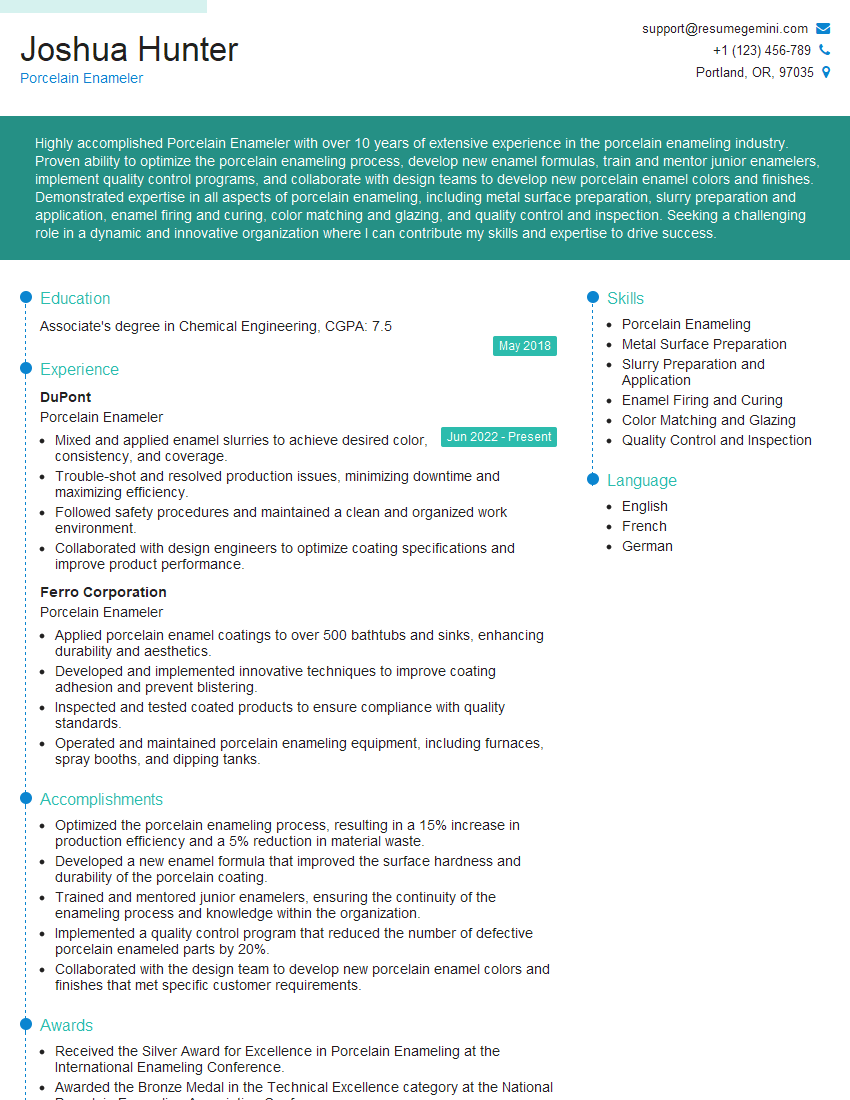

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Porcelain Enameler

1. Explain the role of a porcelain enameler in the manufacturing process.

Porcelain enameling is a process of applying a porcelain finish to a metal surface. The porcelain finish is a thin, durable coating that is resistant to corrosion, abrasion, and heat. Porcelain enamelers are responsible for preparing the metal surface, applying the porcelain finish, and firing the finished product.

- prepare the metal surface by sandblasting, pickling, and rinsing

- apply the porcelain finish by dipping, spraying, or brushing

- fire the finished product in a kiln at a high temperature

2. What are the different types of porcelain enamels?

There are different types of porcelain enamels, each with its properties. The most common type of porcelain enamel is ground coat enamel, which is applied to the metal surface first. Ground coat enamel provides a strong bond between the metal and the enamel finish. Porcelain enamels can be divided into three main categories:

Types of Porcelain Enamels

- Ground coat enamels

- Cover coat enamels

- Specialty enamels

Ground Coat Enamels

- Provide a strong bond between the metal and the enamel finish

- Are applied to the metal surface first

Cover Coat Enamels

- Provide the final color and finish to the enameled product

- Are applied over the ground coat enamel

Specialty Enamels

- Have specific properties, such as resistance to chemicals or heat

- Are used for specific applications, such as cookware or chemical processing equipment

3. What are the advantages of porcelain enameling?

Porcelain enameling offers several advantages over other finishing methods:

- Durability: Porcelain enamel is a very durable finish that is resistant to corrosion, abrasion, and heat.

- Hygiene: Porcelain enamel is a non-porous finish that is easy to clean and sanitize, making it ideal for use in food and beverage applications.

- Aesthetics: Porcelain enamel is available in a wide range of colors and finishes, making it a versatile option for both functional and decorative applications.

4. What are the challenges of porcelain enameling?

There are several potential challenges associated with porcelain enameling:

- Cost: Porcelain enameling can be a relatively expensive finishing process, especially for large or complex products.

- Quality control: Porcelain enameling requires careful quality control to ensure that the finished product meets the desired specifications.

- Environmental concerns: Porcelain enameling can generate hazardous waste, which must be properly disposed of.

5. What are the latest trends in porcelain enameling?

The porcelain enameling industry is constantly evolving, with new trends emerging all the time. Some of the latest trends in porcelain enameling include:

- Digital printing: Digital printing technology is being used to create more complex and colorful designs on porcelain enameled products.

- Sustainable practices: Porcelain enamelers are increasingly adopting sustainable practices to reduce their environmental impact.

- New applications: Porcelain enameling is being used in new and innovative applications, such as architectural panels and solar energy collectors.

6. What are the key skills and qualifications for a porcelain enameler?

Porcelain enamelers must have a strong understanding of the porcelain enameling process and the properties of porcelain enamel. They must also be able to work independently and as part of a team.

- Knowledge of the porcelain enameling process

- Understanding of the properties of porcelain enamel

- Ability to work independently and as part of a team

- Attention to detail

- Problem-solving skills

7. What are the career opportunities for porcelain enamelers?

Porcelain enamelers can find employment in a variety of industries, including:

- Appliance manufacturing

- Automotive industry

- Construction industry

- Chemical processing industry

- Aerospace industry

8. How do you stay up-to-date on the latest trends in porcelain enameling?

I stay up-to-date on the latest trends in porcelain enameling by reading industry publications, attending trade shows, and networking with other porcelain enamelers.

- Read industry publications

- Attend trade shows

- Network with other porcelain enamelers

9. What are your strengths and weaknesses as a porcelain enameler?

My strengths as a porcelain enameler include my attention to detail, my problem-solving skills, and my ability to work independently and as part of a team. My weakness is that I am relatively new to the industry and I am still learning about the different aspects of porcelain enameling.

- Attention to detail

- Problem-solving skills

- Ability to work independently and as part of a team

- Relatively new to the industry

10. What are your salary expectations?

My salary expectations are in line with the industry average for porcelain enamelers with my experience and qualifications. I am also willing to negotiate based on the benefits package and the company’s culture.

- In line with the industry average

- Willing to negotiate based on benefits package and company culture

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Porcelain Enameler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Porcelain Enameler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Porcelain Enamelers are responsible for applying a vitreous coating to metal surfaces for protection and decoration.

1. Prepare Metal Surfaces

Clean, degrease, and prepare metal surfaces to ensure proper adhesion of the enamel coating.

- Sandblast or grind surfaces to remove impurities and create texture.

- Apply chemical treatments or primers to improve adhesion.

2. Apply Enamel Coatings

Mix and apply enamel powders or slurries to metal surfaces using various methods such as dipping, spraying, or brushing.

- Ensure uniform coverage and thickness to meet specifications.

- Control temperature and heating time during firing to achieve desired glaze and adhesion.

3. Fire and Glaze

Heat-treat enamel-coated pieces in ovens or kilns to fuse the enamel to the metal.

- Monitor temperature and atmosphere conditions during firing to prevent defects.

- Glaze surfaces to enhance gloss, durability, and aesthetic appeal.

4. Inspect and Finish

Inspect finished products for quality, defects, and compliance with specifications.

- Identify and correct any imperfections through sanding, polishing, or re-firing.

- Apply protective coatings or finishes to ensure longevity of the enamel surface.

Interview Tips

Preparing thoroughly for a Porcelain Enameler interview can significantly increase your chances of success.

1. Research the Industry and Company

Familiarize yourself with the enamel coating industry, its applications, and the specific company you’re applying to.

- Understand the company’s products, services, and reputation.

- Research the latest trends and advancements in porcelain enameling.

2. Highlight Your Skills and Experience

Emphasize your technical skills in surface preparation, enamel application, firing, and inspection.

- Quantify your accomplishments and provide specific examples of successful projects.

- Discuss your knowledge of different types of enamels, their properties, and applications.

3. Prepare for Technical Questions

Expect questions related to porcelain enameling processes, equipment, and quality control.

- Be comfortable discussing the principles of enamel adhesion, firing techniques, and defect analysis.

- Demonstrate your understanding of safety protocols and environmental regulations.

4. Show Your Passion and Enthusiasm

Convey your genuine interest in porcelain enameling and its applications.

- Discuss your previous projects or hobbies that demonstrate your passion for the craft.

- Express your eagerness to contribute to the team and learn new aspects of the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Porcelain Enameler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.