Feeling lost in a sea of interview questions? Landed that dream interview for Spraying Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Spraying Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

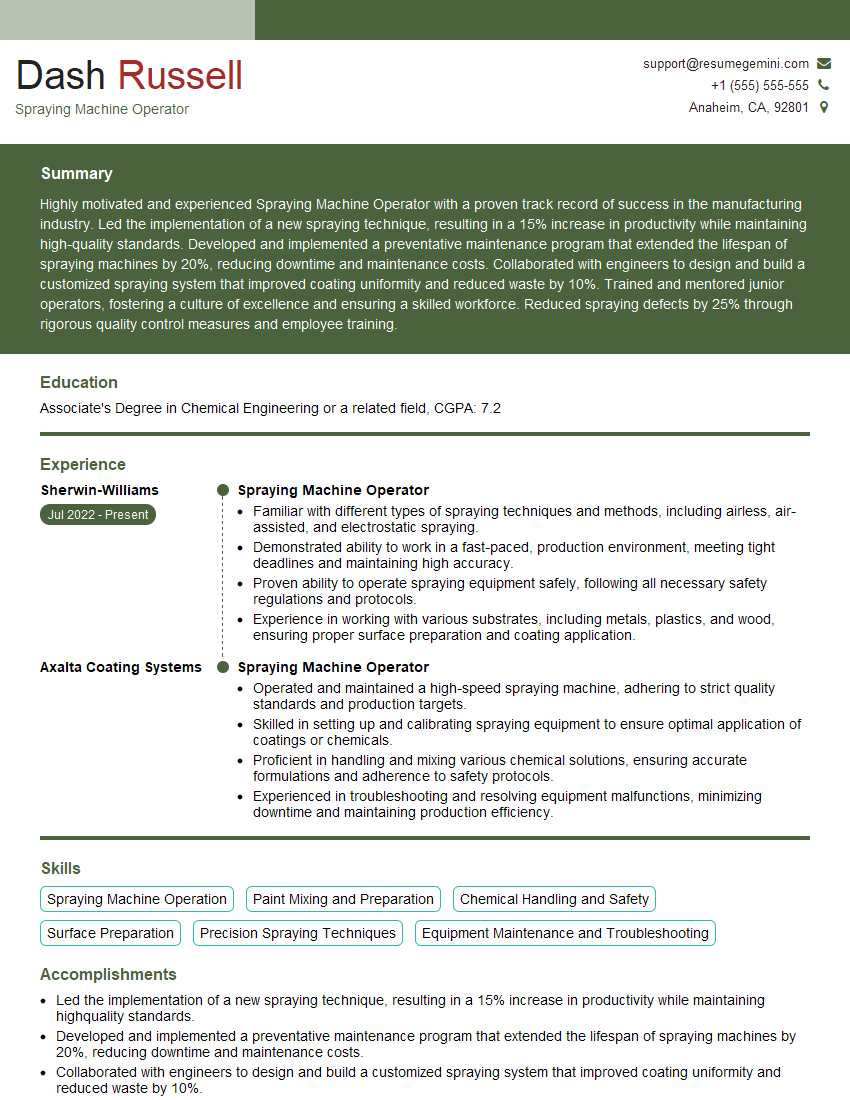

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Spraying Machine Operator

1. What are the different types of spraying machines?

There are various types of spraying machines, each designed for specific applications. Some common types include:

- Airless Sprayers: These machines use high pressure to atomize the coating material, producing a fine, even spray. They are suitable for applying thick coatings, such as paints and epoxies.

- Air-Assisted Airless Sprayers: These machines combine the principles of airless and air spraying, using a combination of high pressure and compressed air to create a finer spray. They are often used for applying primers and base coats.

- Conventional Air Sprayers: These machines use compressed air to atomize the coating material, producing a wide, soft spray. They are suitable for applying thin coatings, such as stains and lacquers.

- HVLP (High Volume, Low Pressure) Sprayers: These machines use a high volume of air at low pressure to create a fine mist. They are designed to minimize overspray and provide a smooth, consistent finish.

- Electrostatic Sprayers: These machines use an electrostatic charge to attract the coating material to the surface being sprayed, resulting in improved coverage and reduced overspray.

2. What are the key parameters to consider when choosing a spraying machine?

- Coating Material: The type of coating material being applied, such as paint, lacquer, or primer, will determine the appropriate type of spraying machine.

- Surface Being Sprayed: The size, shape, and texture of the surface being sprayed will influence the choice of machine and nozzle.

- Desired Finish: The desired finish, whether smooth, textured, or high-gloss, will determine the type of spray pattern and nozzle size required.

- Production Rate: The desired production rate will impact the size and capacity of the machine.

- Environmental Regulations: The local environmental regulations may restrict the use of certain spraying machines or require the use of specific safety equipment.

3. How do you maintain a spraying machine?

Regular maintenance is crucial for ensuring the optimal performance and longevity of a spraying machine. Key maintenance tasks include:

- Cleaning: After each use, the machine should be thoroughly cleaned using the appropriate solvents and cleaning agents to prevent clogging and ensure proper operation.

- Filter Replacement: Filters should be regularly inspected and replaced as needed to prevent contamination of the coating material and maintain the desired spray quality.

- Lubrication: Moving parts, such as bearings and pumps, should be lubricated according to the manufacturer’s specifications to minimize wear and extend the machine’s life.

- Nozzle Inspection: Nozzles should be regularly checked for wear or damage and replaced if necessary to maintain the desired spray pattern and flow rate.

- Pressure Adjustment: The spraying pressure should be adjusted according to the coating material and surface being sprayed to achieve the desired finish.

4. What troubleshooting steps would you take if the spraying machine is not producing a consistent spray pattern?

- Check the Nozzle: The nozzle may be clogged or damaged, resulting in an inconsistent spray pattern. Inspect the nozzle and clean or replace it if necessary.

- Adjust the Pressure: The spraying pressure may be too low or too high, affecting the spray pattern. Adjust the pressure according to the manufacturer’s recommendations.

- Inspect the Filter: A clogged filter can restrict the flow of the coating material, leading to an inconsistent spray pattern. Check the filter and replace it if necesario.

- Check the Air Supply: For air-assisted sprayers, an insufficient or interrupted air supply can cause an inconsistent spray pattern. Ensure that the air compressor is providing adequate pressure and volume.

- Check the Coating Material: The coating material may be too thick or contain impurities that can clog the nozzle or affect the spray pattern.

5. Describe the safety precautions you would observe when operating a spraying machine.

- Wear Protective Equipment: Wear a respirator, safety glasses, gloves, and protective clothing to prevent exposure to fumes, solvents, and overspray.

- Ventilate the Work Area: Ensure adequate ventilation in the work area to prevent the buildup of fumes and solvents.

- Ground the Machine: Ground the spraying machine to prevent static electricity buildup, which can lead to sparks and fires.

- Handle Solvents Safely: Store and handle solvents and cleaning agents properly to avoid spills and fires.

- Follow manufacturer’s instructions: Read and follow the manufacturer’s instructions carefully to ensure safe and efficient operation.

6. How would you calculate the coverage area of a spraying machine?

- Determine Spray Width: Determine the average spray width of the machine using the specified nozzle and pressure.

- Calculate Linear Footage: Multiply the spray width by the length of the area to be sprayed to get the linear footage.

- Convert to Square Footage: Multiply the linear footage by the width of the area to be sprayed to get the square footage.

7. What is the difference between a single-stage and a two-stage spraying machine?

- Single-Stage Sprayers: Single-stage sprayers combine all components, such as the compressor, pump, and fluid reservoir, into a single unit. They are typically smaller and more portable.

- Two-Stage Sprayers: Two-stage sprayers have separate components for the compressor and the fluid section. The compressor provides high-pressure air, while the fluid section stores and delivers the coating material. Two-stage sprayers are larger and more powerful but also more expensive.

8. What are the advantages and disadvantages of using a spray gun with a fan pattern nozzle?

Advantages:

- Provides a wider spray area, reducing the number of passes required.

- Suitable for large surfaces and uneven surfaces.

- Produces a smooth and consistent finish.

Disadvantages:

- Can result in overspray and wasted coating material.

- Requires more skill to achieve a precise application.

9. How would you adjust the atomization of a spraying machine?

- Adjust Spray Tip Size: Using a larger spray tip produces larger droplets and a coarser finish, while a smaller spray tip produces smaller droplets and a finer finish.

- Adjust Spray Pressure: Increasing the spraying pressure results in finer atomization, while decreasing the pressure produces larger droplets.

- Adjust Fluid Viscosity: Thinner coating materials atomize more easily than thicker materials. Adjusting the viscosity by adding solvents or thinners can affect the atomization.

10. What are the common troubleshooting steps for a spraying machine that is not spraying?

- Check Power Supply: Ensure that the machine is properly connected to a power source and that the power switch is turned on.

- Inspect Fluid Supply: Check if there is adequate coating material in the reservoir and that the fluid line is clear and not clogged.

- Examine Spray Tip: Clean or replace the spray tip if it is clogged or damaged.

- Inspect Filter: Check and replace the filter if it is clogged, as it can restrict the flow of coating material.

- Check Air Supply (for air-assisted sprayers): Ensure that the air compressor is providing sufficient air pressure and volume.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Spraying Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Spraying Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Spraying Machine Operator is responsible for operating and maintaining spraying machines used in various industrial and agricultural settings. Their primary duties include:

1. Machine Operation

• Operate spraying machines to apply coatings, chemicals, or other substances onto surfaces or objects.

• Adjust machine settings, such as pressure, flow rate, and nozzle size, to achieve optimal application results.

• Monitor machine performance and make necessary adjustments to ensure efficient operation.

2. Material Preparation and Handling

• Prepare spraying materials, such as paints, coatings, or chemicals, according to specifications.

• Handle and store materials safely, ensuring proper ventilation and adherence to MSDS guidelines.

• Clean and maintain spray equipment, including nozzles, hoses, and filters.

3. Quality Control and Inspection

• Inspect surfaces or objects before and after spraying to ensure proper coverage and quality.

• Identify and correct any defects or imperfections in the spraying process.

• Maintain records of spraying operations, including materials used, settings, and any issues encountered.

4. Safety and Compliance

• Adhere to all safety regulations and guidelines related to spraying operations.

• Wear appropriate personal protective equipment, such as respirators, gloves, and goggles.

• Handle and dispose of spraying materials in accordance with environmental regulations.

Interview Tips

To ace the interview for a Spraying Machine Operator position, consider the following tips and hacks:

1. Research the Company and Role

• Visit the company’s website to learn about their products, services, and culture.

• Review the job description thoroughly to understand the specific requirements and responsibilities of the role.

2. Highlight Relevant Experience

• Quantify your experience with spraying machines, stating the types of machines operated and materials applied.

• Emphasize your skills in machine operation, material preparation, and quality control.

3. Prepare for Technical Questions

• Study the basics of spraying machine operation, including the principles of spraying, nozzle selection, and troubleshooting.

• Be prepared to discuss your knowledge of safety regulations and environmental compliance.

4. Practice Common Interview Questions

• Prepare thoughtful answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?”

• Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

5. Showcase Your Safety Mindset

• Highlight your commitment to safety by describing your experiences in adhering to safety protocols and handling hazardous materials.

• Discuss your understanding of safety regulations and your willingness to follow proper procedures.

6. Ask Thoughtful Questions

• Prepare a list of intelligent questions about the role, the company, and the industry.

• Asking questions demonstrates your interest and engagement, and it gives you an opportunity to clarify any aspects of the job.

Next Step:

Now that you’re armed with the knowledge of Spraying Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Spraying Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini